Geomembranes, also referred to as geomembrana liners, are synthetic membrane liners made from reinforced polymeric materials with extremely low permeability. They are specifically engineered to possess high tensile strength, durability, and chemical resistance, making them an optimal choice for various environmental and geotechnical applications. BPM geomembranes are usually made of synthetic polymers in sheets ranging from 20 mil to 120 mils or 0.5 to 3 mm thickness.

As the professional geomembrane manufacturer and supplier, BPM offers gemembrane liners with different types and thickness for various applications at best factory price.

Quality Geomembranes We Made

Smooth Geomembrane

BPM smooth geomembrane HDPE liner is fabricated by automatic geomembrane production lines and advanced three layered pressing technology in accordance with GRI GM13 standard. Compared with traditional concrete, asphalt and compacted clay, smooth geomembrane HDPE Liner has proven to be far more cost effective, environmentally safe, excellent durable, chemically resistant, fast deployment and easy transportation.. See more on BPM smooth geomembrane HDPE liner…

Textured Geomembrane

BPM textured HDPE geomembrane is made of imported raw material with advanced manufacturing equipment and professional production technology, they are packed in double woven geotextile and strength belt. Our textured HDPE geomembranes are widely applied for such projects which need increased friction between two layers and high steeper slopes as landfills, mining, retaining backfills and waste containment. More information available on BPM textured HDPE geomembrane…

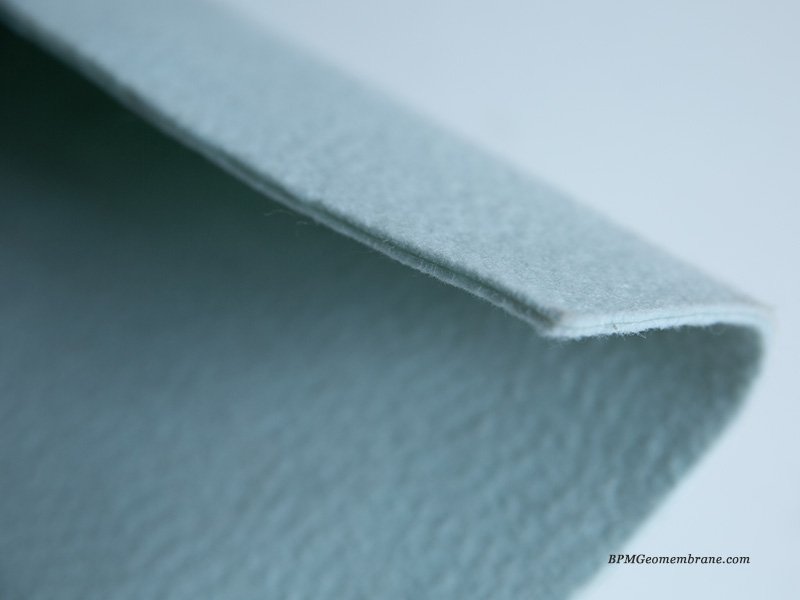

Composite Geomembrane

Composite geomembrane Liner is made by heat-bonding nonwoven or woven geotextile to HDPE geomembranes by calendaring processing technology. It has the functions and advantages of both geotextiles and geomembranes. The geotextile layer increases essential tensile strength and the geomembranes provides excellent impermeability. They are widely used for landfills, roads construction, aquaculture, landscape and agriculture, etc al. Get more about BPM composite Geomembrane liner…

1. What Are Geomembranes?

Geomembranes are impermeable synthetic membrane liners made from various raw polymer resins such as High-Density Polyethylene (HDPE), Linear Low-Density Polyethylene (LLDPE), Polyvinyl Chloride (PVC) or EPDM (Ethylene Propylene Diene Monomer), , and Polypropylene (PP). These resins are processed through extrusion to form sheets of different widths and thicknesses. The properties of geomembranes are influenced by the type of resin used. Additives like antioxidants, plasticizers, fillers, carbon black, and lubricants are often mixed with HDPE and LLDPE resins to enhance performance in different conditions. For instance, carbon black improves resistance against UV radiation, while antioxidants protect against chemical degradation.

Geomembranes often act as large-scale impermeable barriers made of reinforced polymeric materials. They play a crucial role in stabilizing the earth and ensuring containment in applications such as landfill management. By blocking fluids, they can prevent the dispersion of contaminants, and when combined with soil liners or permeable geotextiles, they create composite lining systems for added security.

BPM geomembranes are extensively used across diverse industries including waste management, water treatment, aquaculture, mining, power plants, and civil engineering. They offer reliable solutions for containment and environmental protection in these applications.

2. How To Make Best Geomembranes?

As one of the leading geomembrane liner companies in China, BPM takes pride in manufacturing top-quality geomembranes. With a team of over 160 professionals and a 36,000 square meter factory equipped with state-of-the-art production lines, BPM ensures excellence in geomembrane manufacturing. The factory holds certifications such as ISO9001, ISO14001, and OHSAS18001, and BPM geomembranes have received approvals from TUV, Soncap, SASO, BV, SGS, Intertek, and other esteemed organizations.

Quality control begins with rigorous testing of raw materials, ensuring compliance with BPM’s specifications. The modern factory boasts advanced machines like blowing film technology Geomembrane production lines, extrusion technology Geomembrane production lines, PET Geogrid production lines, and Geotextile production lines. These cutting-edge technologies enable BPM to maintain high product quality, prompt delivery times, and competitive costs, meeting the demands of global customers. BPM’s geomembranes and geosynthetic products are on par with international standards.

BPM geomembranes are manufactured using automatic production lines and advanced pressing technology. Crafted from high-density polyethylene (HDPE) with specially formulated virgin polyethylene resin, these geomembranes offer exceptional quality and performance. The meticulous manufacturing process ensures consistent and reliable HDPE geomembranes that fulfill the stringent requirements of various industries. Whether used for waste containment, lining water treatment facilities, constructing fish ponds, or providing containment in mining operations, BPM geomembranes exhibit durability and resistance to environmental factors. With superior materials and precision manufacturing, BPM geomembranes are trusted solutions for effective containment and protection in a wide range of industrial and engineering applications.

3. What Are Main Categories of BPM Geomembranes?

BPM geomembranes include Smooth HDPE Geomembrane, Textured Geomembrane liner, Composite Geomembrane Liner and LLDPE Geomembrane, etc.

Our smooth HDPE geomembrane liner offers a range of options to suit your specific needs. It is available in three colors icnluding black, white, and green, allowing you to choose the most suitable option for your application. Additionally, the textured geomembrane can be customized with a single or double-sided surface, providing enhanced frictional characteristics and stability.

For projects requiring additional functionality, we offer composite geomembranes, which combine a smooth geomembrane liner with a geotextile layer. This composite design provides added strength, filtration, and separation capabilities, making it ideal for a variety of applications.

For your unique project demands, we offer ODM (Original Design Manufacturing), OEM (Original Equipment Manufacturing), and customization services. This ensures that our geomembrane liners align perfectly with your specific requirements, offering tailored solutions that meet your project’s needs and specifications.

Whether you require a smooth geomembrane liner in a particular color, a textured surface for improved performance, or a composite design for enhanced functionality, our geomembrane liners can be customized to suit your project. BPM geomembrane is dedicated to providing flexible options and delivering products that meet your expectations and deliver superior performance.