HDPE Smooth Geomembrane is a low-permeable synthetic membrane liner and geotechnical engineering material that finds extensive use in water and waste containment applications.

1. What Is HDPE Smooth Geomembrane?

HDPE smooth geomembrane refers to a specialized material made from high-density polyethylene (HDPE) that is used in civil and environmental engineering projects. It is characterized by its smooth surface, which provides a barrier against the seepage of liquids. HDPE geomembranes are known for their excellent chemical resistance, durability, and flexibility.

These HDPE geomembranes are widely used in various applications, including landfill waterproofing systems. In such projects, the HDPE smooth geomembrane serves as a critical component to prevent the leakage of waste materials and contaminants into the surrounding environment. Failure of the geomembrane liner can have severe consequences, which is why quality inspections and proper installation are essential.

In some cases, dual waterproofing systems may be implemented in large-scale waste containment projects to ensure redundancy and minimize the risk of failure. This involves the use of multiple layers of HDPE smooth geomembrane to provide added protection.

When selecting an HDPE smooth geomembrane, it is important to consider factors such as the specific project requirements, including size and color. BPM, a reputable manufacturer and supplier with over 13 years of experience, offers a wide range of HDPE smooth geomembranes in various sizes and colors at competitive factory prices.

Choosing the best HDPE smooth geomembrane for a project is crucial for ensuring optimal performance, durability, and the overall success of the project.

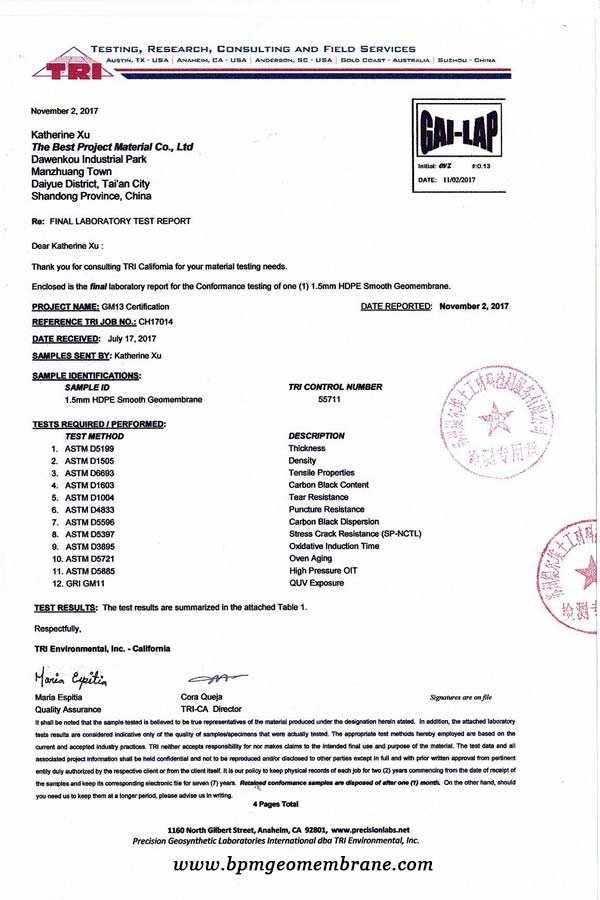

2. Testing of BPM HDPE Smooth Geomembrane Approved by GAI-LAP in USA

We are pleased to inform our American client that BPM’s HDPE smooth geomembrane has successfully undergone comprehensive testing at TRI/Environmental USA, a member of the Geosynthetic Accreditation Institute-Laboratory Accreditation Program (GAI-LAP) specializing in geomembrane testing.

The testing process involved providing HDPE geomembrane samples to the client for evaluation. Basic physical properties testing was completed within the first month, while the evaluation of oven aging and high-pressure oxidative induction time (OIT) took approximately three months. The latter stage is particularly important as it assesses the long-term properties and durability of the geomembrane.

We are proud to announce that the testing report for BPM’s 1.5mm HDPE smooth geomembrane landfill liner has received approval from GAI-LAP. The testing values of our HDPE geomembrane liner not only met but significantly exceeded the GM13 standard, with some values surpassing it by up to 40%. This demonstrates the exceptional quality and performance of our HDPE geomembrane products.

We are confident that our high-quality HDPE smooth geomembrane will meet and surpass the requirements of your waste containment project. Our commitment to providing reliable and durable geomembrane solutions ensures that your project will be carried out with the utmost efficiency and effectiveness.

Please feel free to reach out to us with any further inquiries or to proceed with your order. We look forward to the opportunity to serve you and contribute to the success of your project.

3. What Are Advantages of BPM HDPE Smooth HDPE Geomembrane?

BPM HDPE smooth geomembranes offer a combination of low permeability, durability, chemical resistance, flexibility, and seam integrity. These advantages make them an excellent choice for various containment applications, including environmental protection, water management, waste management, and industrial applications.

3.1 Virgin Raw Material

BPM HDPE smooth geomembranes are made from high-quality virgin raw materials, ensuring consistent quality and performance.

3.2 Low Permeability

HDPE geomembranes have low permeability, providing an effective barrier against the migration of liquids, gases, and contaminants. This characteristic is essential for containment applications where leakage prevention is crucial.

3. Smooth Surface

The smooth surface of HDPE geomembranes offers excellent resistance to punctures and tears. It reduces the risk of damage during installation and enhances the long-term integrity of containment systems.

3.4 Flexible

Despite its high density and strength, HDPE geomembranes are flexible and can conform to irregular surfaces. This flexibility simplifies installation, especially in projects with complex geometries or uneven substrates.

3.5 Excellent Chemical Resistance

HDPE geomembranes exhibit exceptional resistance to a wide range of chemicals, including acids, alkalis, and organic solvents. This chemical resistance makes them suitable for applications where containment of hazardous substances is required, such as in landfills, industrial ponds, and chemical storage areas.

3.6 Outstanding Stress Crack Capacity

HDPE geomembranes have excellent resistance to stress cracking, which can result from external forces or environmental factors. This property ensures the geomembrane’s stability and prevents the propagation of cracks.

3.7 Durability

HDPE geomembranes are known for their durability and long service life. They can withstand harsh environmental conditions, including exposure to UV radiation, temperature variations, and mechanical stresses, without significant degradation.

3.8 UV Resistance

BPM HDPE smooth geomembranes are formulated with UV stabilizers to enhance their resistance to ultraviolet radiation. This feature extends their lifespan and maintains their integrity when exposed to sunlight.

3.9 Temperature Resistance

HDPE geomembranes have good temperature resistance, allowing them to perform effectively in both hot and cold climates. They can withstand temperature extremes without losing their physical properties or performance.

3.10 Seam Integrity

HDPE geomembranes can be heat-welded to form strong, impermeable seams. This welding technique ensures the integrity of containment systems by creating secure connections between geomembrane panels, preventing leakage or seepage.

3.11 Compliance with GRI GM13 Standard

BPM HDPE smooth geomembranes comply with the Geosynthetic Research Institute’s GM13 standard. This standard establishes guidelines and requirements for the performance and testing of geomembranes, ensuring high-quality products.

3.12 OEM/ODM Availability

BPM offers OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services, allowing for customization and tailored solutions to meet specific project requirements.

4. Case Study Of BPM HDPE Smooth Geomembrane for Landfill In USA

BPM Geomembrane is thrilled to announce that BPM has successfully secured an order for 10,000 square meters of HDPE geomembrane liner for the landfill project. This achievement not only addresses the local waste treatment issue but also provides an effective solution to ensure environmental protection.

In addition to the HDPE geomembrane liner, our customer has also placed orders for geotextile and geocomposite materials. These additional geosynthetic products play a vital role in enhancing the overall performance of the landfill system. Together, the geomembrane, geotextile, and geocomposite materials form a comprehensive system that provides waterproofing, prevents leakage, and facilitates filtration within the landfill project.

By adopting this integrated approach, the waste containment system ensures the overall integrity and efficiency of the landfill. The HDPE geomembrane liner acts as a reliable barrier, preventing the migration of contaminants into the surrounding environment. The geotextile materials offer filtration and separation capabilities, minimizing soil erosion and enhancing drainage efficiency. The geocomposite materials provide additional reinforcement and protection to the overall system.

This comprehensive geosynthetic system meets the requirements and expectations of our valued customer. It not only ensures the effective containment and management of waste but also contributes to the long-term sustainability of the landfill project.

We are grateful for the trust our customer has placed in us and are committed to delivering high-quality products and services. BPM looks forward to a successful collaboration and the opportunity to contribute to the success of the landfill project.

5. Specifications of BPM HDPE Smooth Geomembrane for Landfill Project

For the waste containment project in the USA, BPM offers a 1.0 mm HDPE smooth geomembrane that meets the specific requirements of the application. Here are the specifications of the BPM HDPE smooth geomembrane for the waste containment project:

- Material: High-Density Polyethylene (HDPE)

- Thickness: 1.0 mm (40 mils)

- Roll Width: Customizable based on project requirements

- Roll Length: Customizable based on project requirements

- Color: Black (standard), other colors available upon request

- Surface: Smooth

- Tensile Strength: ≥ 20 MPa (ASTM D6693)

- Elongation at Break: ≥ 400% (ASTM D6693)

- Tear Resistance: ≥ 80 N (ASTM D1004)

- Puncture Resistance: ≥ 200 N (ASTM D4833)

- Carbon Black Content: ≥ 2.0% (ASTM D1603)

- UV Resistance: Excellent (ASTM G154)

- Chemical Resistance: Excellent (resistant to a wide range of chemicals typically found in waste containment environments)

- Seam Strength: ≥ 70% of the parent material (ASTM D6392)

These specifications ensure that the BPM HDPE smooth geomembrane provides a durable, impermeable barrier for waste containment applications. It effectively prevents the seepage of contaminants and protects the environment from potential pollution.

Please note that these specifications can be customized based on the specific requirements of your waste containment project. BPM is dedicated to providing high-quality geomembrane products that meet the highest industry standards and customer expectations.

BPM had provided many types of effective and states of the art geomembranes and other geosynthetics to over 36 countries. BPM is not only manufacturing best quality geomembrane products but also providing professional design and installation service. OEM, ODM, custom development and fabrication are also available.