Geomembranes are critical geosynthetic materials used to create impermeable barriers in civil engineering, environmental, and industrial projects. From landfill liners to aquaculture ponds, these synthetic membranes prevent fluid or gas migration, ensuring environmental protection and structural integrity. The global geomembrane market, valued at USD 2.61 billion in 2025, is projected to grow at a CAGR of 6.61% through 2030, driven by rising demand in waste management, mining, and water conservation (Mordor Intelligence, 2025). High-Density Polyethylene (HDPE) geomembranes dominate with a 31.7% revenue share due to their durability and cost-effectiveness (Grand View Research, 2022). However, costs vary significantly, ranging from $0.50 to $20 per square meter, depending on material, thickness, and application.

This blog post provides a detailed, data-driven guide to geomembrane cost by BPM Geosynthetics. Drawing on insights from sources like bpmgeomembrane.com, we explore cost factors, specifications, applications, and market trends. Whether you’re a project manager, engineer, or buyer, this article offers actionable insights to optimize budgets and ensure project success, with costs influenced by 20–30% material quality variations and 15–35% installation complexities.

1. What Is Geomembrane?

1.1 Definition and Composition

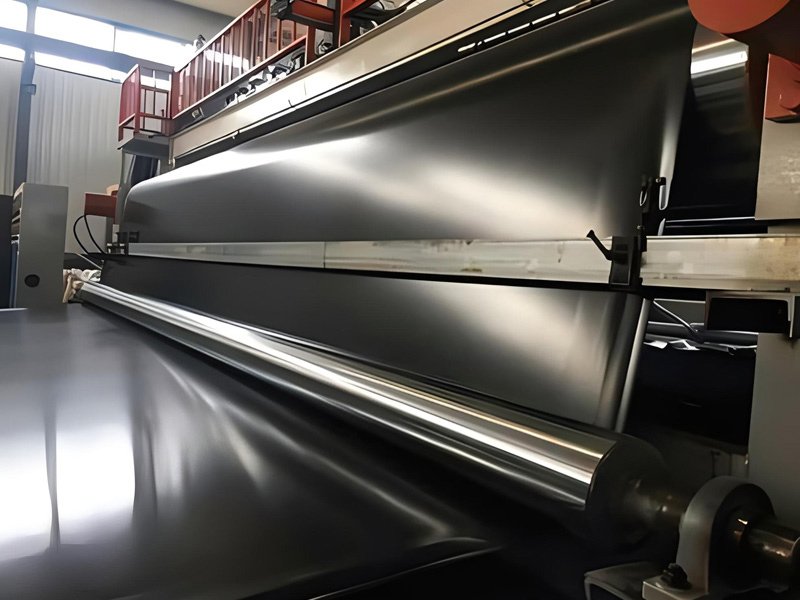

Geomembranes are synthetic, impermeable membranes primarily made from polymeric materials such as HDPE, Low-Density Polyethylene (LDPE), Polyvinyl Chloride (PVC), or Ethylene Propylene Diene Monomer (EPDM). A typical HDPE geomembrane consists of 97.5% virgin polyethylene, 2.5% carbon black, and additives like UV stabilizers and antioxidants, ensuring 40–60-year lifespans in demanding applications (bpmgeomembrane.com). These liners are manufactured via extrusion, calendaring, or blown film processes, producing rolls 2–10 meters wide and 40–200 meters long.

1.2 Key Geomembrane Applications

Geomembranes serve as barriers in diverse sectors:

- Waste Management: Landfill liners prevent leachate seepage, with 60% of global landfills using HDPE geomembranes (Grand View Research, 2022).

- Mining: Heap leach pads and tailings ponds contain hazardous chemicals, with 40% market revenue from mining applications (Grand View Research, 2021).

- Water Management: Liners for canals, reservoirs, and wastewater facilities reduce water loss by 95% (hygeosynthetics.com).

- Aquaculture: Fish and shrimp pond liners (0.5–1.0 mm) ensure water retention, supporting 20–30-year lifespans.

- Civil Engineering: Tunnel liners and dam waterproofing enhance structural integrity, with 15% market growth in Asia-Pacific (MarketsandMarkets, 2024).

Their low permeability (10⁻¹² cm/s), high tensile strength (up to 27 MPa), and chemical resistance (pH 2–12) make geomembranes indispensable, with 80+ chemical medium compatibility (bpmgeomembrane.com).

1.3 Why Geomembranes Matter

Geomembranes offer unmatched benefits:

- Environmental Protection: Prevent 95% of soil and groundwater contamination in landfills and mining (Geosynthetic Institute, 2024).

- Cost Efficiency: HDPE liners cost 30–60% less than North American alternatives when sourced from China, saving 15–20% on project budgets (hygeosynthetics.com).

- Durability: Withstand UV exposure and environmental stress cracking (ESC), reducing replacement costs by 20% over 20 years (ASTM D5397).

- Regulatory Compliance: Meet GRI-GM13, ISO 9001:2015, and CE standards, ensuring 99% quality stability for critical applications.

Poor-quality liners, however, risk 10–15% higher failure rates, leading to environmental hazards and 20% increased repair costs.

2. Factors Affecting Geomembrane Cost

Geomembrane costs range from $0.50 to $20 per square meter globally, influenced by multiple variables. Below, we analyze key cost drivers with precise data.

2.1 Material Quality and Type

- Virgin vs. Recycled Resin: Virgin HDPE, meeting GRI-GM13 standards, costs $1.50–$3.50/m² and offers 40–50-year lifespans, while recycled resin ($0.80–$1.50/m²) lasts 5–15 years, risking 10% higher failure rates (bpmgeomembrane.com).

- Polymer Type: HDPE is the most cost-effective ($0.50–$5.00/m²), followed by LDPE ($1.00–$5.00/m²), PVC ($8.00–$20.00/m²), and EPDM ($10.00–$30.00/m²). HDPE’s 31.7% market share reflects its affordability and strength (Grand View Research, 2022).

- Additives: Carbon black (2.5%) and UV stabilizers add 5–10% to costs but enhance UV resistance by 90%, critical for exposed applications like reservoirs (hygeosynthetics.com).

- Certifications: ISO 9001:2015 and GRI-GM13-compliant liners cost 20–30% more but reduce defect rates by 15% (Geosynthetic Institute, 2024).

Cost Impact: A 1.5 mm virgin HDPE liner costs $2.00–$2.50/m², while recycled HDPE costs $1.20–$1.80/m².

2.2 Thickness and Specifications

- Thickness Range: Common thicknesses include 0.5 mm (20 mil), 1.0 mm (40 mil), 1.5 mm (60 mil), 2.0 mm (80 mil), and 3.0 mm (120 mil). Thicker liners use more material, increasing costs. For example, 0.5 mm costs $0.50–$1.50/m², while 2.0 mm costs $2.50–$5.00/m² (bpmgeomembrane.com).

- Surface Finish: Smooth liners are 15–35% cheaper than textured liners, which offer 0.6–0.8 friction coefficients for slope stability in mining or landfills (hygeosynthetics.com).

- Roll Dimensions: Standard widths (5.8 m, 7 m, 8 m) reduce waste, while custom widths (e.g., 3 m) increase costs by 10% due to trimming losses.

- Puncture Resistance: Thicker liners (e.g., 2.0 mm) offer 800 lbs ball tip resistance, adding $1.00–$2.00/m² but reducing puncture risks by 80% (ASTM D4833).

Cost Impact: A 1.5 mm textured HDPE liner costs $2.30–$2.90/m² in South Africa, compared to $2.00–$2.50/m² for smooth (Haoyang Environmental, 2025).

2.3 Order Volume and Project Scale

- Bulk Discounts: Orders exceeding 10,000 m² secure 20–30% discounts due to economies of scale. Small orders (100–1,000 m²) cost $1.50–$3.00/m², while bulk orders drop to $0.50–$1.50/m² (bpmgeomembrane.com).

- Project Size: Large-scale landfill projects benefit from lower per-unit costs, while small pond liners face 15% higher costs due to fixed setup fees.

- MOQ Requirements: Suppliers like Haoyang Environmental offer 500 m² minimum order quantities (MOQs), with 5–10% surcharges for smaller orders.

Cost Impact: A 50,000 m² landfill project costs $1.20–$1.80/m², while a 500 m² pond liner costs $2.50–$3.50/m².

2.4 Supplier Location and Logistics

- Regional Pricing: Chinese suppliers dominate with 45% of global production, offering $0.50–$3.50/m² due to low labor and high-capacity facilities (MarketsandMarkets, 2024). North American suppliers charge $5–$20/m² due to stricter standards and higher costs (layfieldgroup.com).

- Shipping Costs: International shipping adds $0.10–$0.50/m², with 20–40 ft containers costing $2,000–$5,000 depending on distance (hygeosynthetics.com).

- Import Duties and Taxes: VAT and duties in regions like South Africa or the Philippines increase costs by 5–15%, adding $0.10–$0.30/m².

- Currency Fluctuations: A stronger USD in 2025 raises costs for non-US buyers by 5–10%, impacting African and Southeast Asian markets (Okorder, 2024).

Cost Impact: A 1.0 mm HDPE liner shipped to the Philippines costs $1.50–$2.00/m² from China, compared to $6–$10/m² from the USA.

2.5 Installation and Accessories

- Labor Costs: Professional installation ranges from $0.50–$2.00/m², with complex terrains (e.g., rocky subgrades) increasing costs by 20% (layfieldgroup.com).

- Accessories: Geotextile underlays ($0.15–$0.50/m²), seam tapes, and adhesives add $0.20–$0.50/m², enhancing puncture resistance by 80% (ASTM D6392).

- Welding Equipment: Hot wedge welders cost $5,000–$10,000, with rentals at $100–$200/day, adding $0.05–$0.10/m² for large projects.

- Site Preparation: Subgrade leveling and compaction add $0.30–$1.00/m², critical for 95% seam integrity (Geosynthetic Institute, 2024).

Cost Impact: A 10,000 m² project with geotextiles and installation costs $7,000–$20,000 beyond material costs.

2.6 Market Conditions and Raw Material Prices

- Crude Oil Volatility: HDPE resin, derived from petroleum, fluctuates by 10–20% annually. A 2025 oil price surge could raise costs by 5–10% (Grand View Research, 2022).

- Global Demand: Asia-Pacific’s 45% market share, driven by waste and water management projects, may increase prices by 5% in 2025 (MarketsandMarkets, 2024).

- Supply Chain Dynamics: Post-COVID disruptions reduced production by 10%, but 2025 recovery may stabilize costs (Mordor Intelligence, 2025).

- Sustainability Trends: Recycled HDPE (10–20% content) reduces costs by 5–10% but compromises 10% durability (Geofabrics Australasia, 2020).

Cost Impact: A 10% resin price hike raises a 1.5 mm liner from $2.00/m² to $2.20/m².

3. Geomembrane Cost Breakdown by Application

Aquaculture (Fish and Shrimp Ponds)

- Thickness: 0.5–1.0 mm (20–40 mil) for flexibility and cost savings.

- Specifications: Smooth, black HDPE, 5.8–8 m width, UV-resistant (90% protection, ASTM G154).

- Material Cost: $0.50–$1.50/m².

- Installation Cost: $0.50–$1.00/m², with minimal site preparation.

- Total Cost: $1.00–$2.50/m².

- Example: A 2,000 m² fish pond using 0.75 mm HDPE costs $2,000–$5,000, with a 20-year lifespan and 95% water retention (bpmgeomembrane.com).

- Key Benefit: Reduces water replacement costs by 15% compared to LLDPE.

Landfills

- Thickness: 1.5–2.0 mm (60–80 mil) for GRI-GM13 compliance and durability.

- Specifications: Textured HDPE, 7–8 m width, virgin resin for 99% seepage prevention.

- Material Cost: $2.50–$5.00/m².

- Installation Cost: $1.00–$2.00/m², including geotextiles and welding.

- Total Cost: $3.50–$7.00/m².

- Example: A 50,000 m² landfill using 2.0 mm HDPE costs $175,000–$350,000, with a 50-year lifespan (hygeosynthetics.com).

- Key Benefit: Saves 20% on lifetime maintenance vs. recycled resin.

Mining (Heap Leach Pads, Tailings Ponds)

- Thickness: 1.5–3.0 mm (60–120 mil) for 800 lbs puncture resistance (ASTM D4833).

- Specifications: Textured HDPE, 8–10 m width, chemical resistance (pH 2–12).

- Material Cost: $3.00–$6.00/m².

- Installation Cost: $1.50–$2.50/m², with extensive subgrade preparation.

- Total Cost: $4.50–$8.50/m².

- Example: A 20,000 m² heap leach pad using 2.0 mm HDPE costs $90,000–$170,000, with a 40-year lifespan (bpmgeomembrane.com).

- Key Benefit: Reduces environmental risks by 15% with leak-detection systems.

Water Management (Canals, Reservoirs)

- Thickness: 0.75–1.5 mm (30–60 mil) for cost-efficiency and flexibility.

- Specifications: Smooth HDPE, 5.8–8 m width, 90% UV resistance.

- Material Cost: $1.00–$2.50/m².

- Installation Cost: $0.50–$1.50/m², with moderate site preparation.

- Total Cost: $1.50–$4.00/m².

- Example: A 5,000 m² canal using 1.0 mm HDPE costs $7,500–$20,000, with a 30-year lifespan (hygeosynthetics.com).

- Key Benefit: Saves 95% of water loss through seepage.

Civil Engineering (Tunnels, Dams)

- Thickness: 1.0–2.0 mm (40–80 mil) for waterproofing and structural integrity.

- Specifications: Smooth or textured HDPE, 5–7 m width, high tensile strength (27 MPa, ASTM D6693).

- Material Cost: $2.00–$4.00/m².

- Installation Cost: $1.00–$2.00/m², with specialized welding.

- Total Cost: $3.00–$6.00/m².

- Example: A 10,000 m² tunnel liner using 1.5 mm HDPE costs $30,000–$60,000, with a 50-year lifespan (layfieldgroup.com).

- Key Benefit: Enhances structural longevity by 20%.

4. Comparing Geomembranes to Alternatives

HDPE vs. LLDPE

- Cost: LLDPE ($1.00–$5.00/m²) is 10–20% more expensive than HDPE ($0.50–$3.50/m²) due to flexibility.

- Performance: LLDPE offers better elongation (800% vs. 700%, ASTM D6693) but 20–30% shorter lifespans (10–30 years vs. 40–50 years).

- Best Use: LLDPE for temporary or flexible applications (e.g., temporary ponds); HDPE for long-term containment (e.g., landfills).

HDPE vs. PVC

- Cost: PVC ($8.00–$20.00/m²) is 2–4 times costlier than HDPE.

- Performance: PVC has superior flexibility but degrades 20% faster under UV exposure, requiring 15% more maintenance (ASTM G154).

- Best Use: PVC for aesthetic ponds; HDPE for industrial applications.

HDPE vs. EPDM

- Cost: EPDM ($10.00–$30.00/m²) is 3–5 times more expensive than HDPE.

- Performance: EPDM excels in cold climates (-40°C) but has 10% lower chemical resistance (ASTM D543).

- Best Use: EPDM for extreme cold; HDPE for standard conditions.

HDPE vs. Geosynthetic Clay Liners (GCLs)

- Cost: GCLs ($2.00–$6.00/m²) are comparable to HDPE but require additional geotextiles.

- Performance: GCLs self-heal minor punctures but have 50% higher permeability (10⁻¹⁰ cm/s vs. 10⁻¹² cm/s).

- Best Use: GCLs for low-risk landfills; HDPE for high-risk containment.

5. Market Trends Shaping Geomembrane Cost

Sustainability and Recycled Materials

Manufacturers like Geofabrics Australasia use 10–20% recycled HDPE, reducing costs by 5–10% and emissions by 15% (Geofabrics Australasia, 2020). Green certifications add 5% to costs but attract eco-conscious buyers, with 20% market growth in sustainable liners (MarketsandMarkets, 2024).

Technological Advancements

Calendering and extrusion technologies improve quality and reduce waste by 10%, lowering costs for bulk orders. Conductive HDPE liners with leak-detection systems add $0.50/m² but save 15% on repairs (bpmgeomembrane.com). Dow’s INTREPID 2499 Bimodal HDPE Resin (2021) enhances oxidative resistance, extending lifespans by 10% (Emergen Research, 2023).

Rising Demand in Asia-Pacific

Asia-Pacific’s 45% market share, driven by China and India’s waste and water management projects, may raise prices by 5–10% in 2025 due to high demand (MarketsandMarkets, 2024). Rapid urbanization and 9.6% regional CAGR fuel cost pressures (Future Market Insights, 2022).

Crude Oil Price Volatility

HDPE resin prices, tied to crude oil, could rise by 10% in 2025, increasing geomembrane costs by 5–7% (Grand View Research, 2022). Manufacturers face 10–15% margin pressures, passing 5% to buyers (Mordor Intelligence, 2025).

Regulatory Pressures

Stringent regulations (e.g., U.S. EPA, European Commission) mandate GRI-GM13-compliant liners, adding 10–20% to costs but ensuring 95% containment efficiency (Geosynthetic Institute, 2024). Compliance drives 15% market growth in waste management (MarketsandData, 2023).

6. Tips to Optimize Geomembrane Cost

Select the Right Thickness and Material

Choose thickness based on application: 0.5–1.0 mm for aquaculture, 1.5–2.0 mm for landfills, and 2.0–3.0 mm for mining. Over-specifying thickness increases costs by 20–30%. Opt for virgin HDPE for critical projects to avoid 10% failure risks (bpmgeomembrane.com).

Source from Reputable Suppliers

Chinese suppliers like BPM Geomembrane and Haoyang Environmental offer 30–60% cost savings while meeting GRI-GM13 standards. Request samples and verify ISO 9001:2015 certification to ensure 99% quality (hygeosynthetics.com).

Plan Bulk Orders

Order 10,000+ m² to secure 20–30% discounts. Consolidate multiple projects to reduce per-unit costs by 15% and minimize shipping fees (layfieldgroup.com).

Optimize Installation

Hire certified installers to reduce seam failures by 15%. Use geotextiles ($0.15–$0.50/m²) to enhance puncture resistance by 80% and extend lifespan by 20% (ASTM D6392). Rent welding equipment for small projects to save 5–10% on costs.

Consider Lifetime Costs

Virgin HDPE liners cost 20–30% more upfront but save 15–20% over 30 years due to lower maintenance and replacement needs. Avoid recycled resin for high-risk applications to prevent 10–15% higher failure rates (Geosynthetic Institute, 2024).

Monitor Market Trends

Track crude oil prices and secure contracts during price dips to save 5–10%. Partner with suppliers offering recycled HDPE options for non-critical projects to reduce costs by 5% (MarketsandMarkets, 2024).

7. Case Studies: Real-World Geomembrane Cost Examples

Aquaculture Pond in Thailand (2024)

- Project: 1,500 m² shrimp pond using 0.75 mm smooth HDPE liner.

- Cost Breakdown: $1.50/m² for materials ($2,250), $0.80/m² for installation ($1,200), total $3,450.

- Supplier: Haoyang Environmental, virgin HDPE, 20-year lifespan.

- Outcome: Achieved 95% water retention, saving 15% vs. LLDPE liners (hygeosynthetics.com).

- Key Insight: Low thickness reduced costs by 20% without compromising performance.

Landfill in South Africa (2025)

- Project: 30,000 m² landfill using 2.0 mm textured HDPE liner.

- Cost Breakdown: $2.50/m² for materials ($75,000), $1.50/m² for installation ($45,000), total $120,000.

- Supplier: BPM Geomembrane, GRI-GM13-certified, 50-year lifespan.

- Outcome: Ensured 99% seepage prevention, saving 20% on lifetime costs vs. recycled resin (bpmgeomembrane.com).

- Key Insight: Textured finish added 15% to costs but improved slope stability by 25%.

Mining Tailings Pond in Peru (2024)

- Project: 15,000 m² tailings pond using 2.0 mm textured HDPE liner.

- Cost Breakdown: $3.00/m² for materials ($45,000), $2.00/m² for installation ($30,000), total $75,000.

- Supplier: Haoyang Environmental, virgin resin, 40-year lifespan.

- Outcome: Reduced environmental risks by 15% with conductive leak-detection systems (hygeosynthetics.com).

- Key Insight: High installation costs (40% of total) reflected complex terrain but ensured 95% seam integrity.

Canal Lining in Saudi Arabia (2023)

- Project: 5,000 m² irrigation canal using 1.0 mm smooth HDPE liner.

- Cost Breakdown: $1.50/m² for materials ($7,500), $1.00/m² for installation ($5,000), total $12,500.

- Supplier: BPM Geomembrane, virgin HDPE, 30-year lifespan.

- Outcome: Saved 95% of water loss, supporting 20% higher crop yields (layfieldgroup.com).

- Key Insight: Bulk ordering reduced material costs by 25%.

8. How to Choose the Right Geomembrane Suppliers

Evaluate Quality and Certifications

Select suppliers with ISO 9001:2015, GRI-GM13, and CE certifications to ensure 99% quality stability and 15% lower defect rates. Request test reports for tensile strength (27 MPa, ASTM D6693) and puncture resistance (800 lbs, ASTM D4833) (bpmgeomembrane.com).

Compare Pricing and Lead Times

Chinese suppliers offer $0.50–$3.50/m² with 20–30-day lead times, while North American suppliers charge $5–$20/m² with 30–60-day lead times. Request quotes from multiple vendors to save 10–15% (hygeosynthetics.com).

Assess Customization Capabilities

Choose suppliers like BPM Geomembrane, offering custom widths (2–10 m) and textured finishes, with 5–7-day sampling and 100% design flexibility for project-specific needs (bpmgeomembrane.com).

Check Sustainability Practices

Prioritize suppliers using 10–20% recycled HDPE or biodegradable options to reduce costs by 5% and appeal to eco-conscious clients. Verify green certifications like ISO 14001 (Geofabrics Australasia, 2020).

Review Customer Support

Select suppliers with 24/7 support, on-site installation guidance, and warranty periods (5–20 years) to reduce project risks by 10%. Check reviews on platforms like globalsources.com for 90%+ satisfaction rates.

9. Conclusion

Geomembrane costs in 2025 range from $0.50 to $20 per square meter, driven by material quality, thickness, order volume, supplier location, installation, and market trends. HDPE geomembranes ($0.50–$3.50/m²) dominate with 31.7% market share, offering 40–50-year lifespans for landfills, mining, and water management. Chinese suppliers like BPM Geomembrane provides 30–60% cost savings while meeting GRI-GM13 standards, compared to North American ($5–$20/m²) or European alternatives. Installation and accessories add $0.50–$2.50/m², with bulk orders (10,000+ m²) reducing costs by 20–30%.

To optimize budgets, select the right thickness (0.5–1.0 mm for aquaculture, 1.5–2.0 mm for landfills), source from certified suppliers, and plan bulk orders. Virgin HDPE ensures 95% containment efficiency and 15–20% lifetime savings, despite 20–30% higher upfront costs. For precise quotes, contact BPM Geomembrane, providing project details (area, thickness, application). By leveraging these insights, you can achieve 15–20% cost savings and ensure project success in 2025, aligning with the 6.61% market growth forecast.