In the demanding fields of civil engineering, environmental protection, and resource management, the integrity of containment systems is non-negotiable. Whether it’s safeguarding precious groundwater, managing hazardous waste, lining critical infrastructure, or enabling sustainable mining operations, the High-Density Polyethylene (HDPE) geomembrane stands as a cornerstone of reliable and long-lasting containment. Its exceptional strength, chemical resistance, and UV stability make it the material of choice for an astonishing array of critical applications.However, the market for HDPE geomembranes is diverse, with numerous manufacturers offering products that vary significantly in quality, specifications, and specialized features. Selecting the Best HDPE geomembranes for a specific project requires a deep understanding of its properties, compliance with industry standards, and consideration of the unique demands of the application.

At The Best Project Material Co., Ltd (BPM Geomembrane), we are at the forefront of geosynthetic innovation, committed to providing engineers, project managers, and environmental specialists with the highest quality containment solutions. Drawing on extensive industry expertise and a meticulous review process, our team has thoroughly evaluated the leading HDPE geomembranes available in 2025. We’ve delved into detailed specifications, manufacturing processes, installation considerations, and real-world performance data to bring you a comprehensive guide to the top performers. Our goal is to provide unparalleled insights and data-driven recommendations, empowering you to make the most informed decision for your next critical containment project.

1. The 5 Best HDPE Geomembranes Review

- Best Overall HDPE Geomembrane: BPM Smooth HDPE Geomembrane

- Best Textured HDPE Geomembrane for Slopes: BPM Textured HDPE Geomembrane

- Best for Extreme Chemical Resistance: Solmax HDPE Geomembrane

- Best for Elevated Temperatures: GSE HDPE Geomembrane

- Best for Very Large-Scale Projects (Pre-Fabrication): AGRU Sure-Grip HDPE Liner

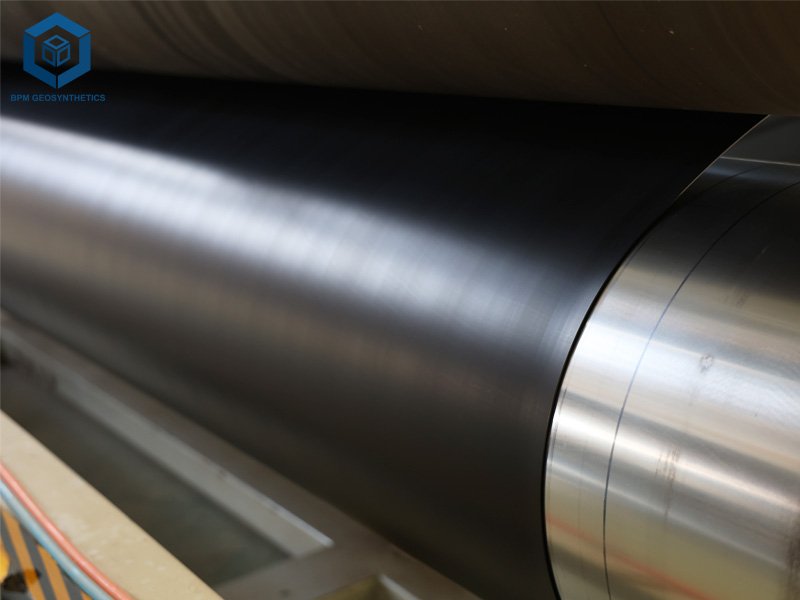

1.1 Best Overall HDPE Geomembrane: BPM Smooth HDPE Geomembrane

Key Features: High tensile strength, excellent chemical resistance, exceptional UV stability, low permeability, high puncture resistance, easily weldable.

What we like: The BPM Smooth HDPE Geomembrane from The Best Project Material Co., Ltd. (BPM Geosynthetics) truly stands out as the best overall choice due to its balanced performance across all critical parameters. Manufactured from virgin HDPE resin, it boasts exceptional tensile strength (typically 27-30 MPa for 1.5mm thickness, following GRI GM13), ensuring robust long-term performance under significant stress. Its chemical resistance is unparalleled, making it suitable for a wide array of industrial effluents and hazardous waste. With a carbon black content of 2-3%, it offers superior UV stability, crucial for exposed applications. The very low permeability (hydraulic conductivity of 10−14 to 10−16 cm/s) provides a nearly impermeable barrier, and its excellent weldability ensures high-integrity seams. This liner is a workhorse, delivering consistent, reliable performance for a vast range of demanding projects.

What we don’t: While excellent in overall performance, its smooth surface may require careful consideration on very steep slopes, where textured options might offer better friction.

Typical Specifications:

- Typical Thicknesses Available:5 mm, 0.75 mm, 1.0 mm, 1.5 mm, 2.0 mm, 2.5 mm, 3.0 mm

- Conformance Standard:GRI GM13

- Tensile Strength (Yield/Break, 1.5mm):≥15.0 MPa/≥27.0 MPa

- Elongation (Yield/Break, 1.5mm):≥12%/≥700%

- Tear Resistance (1.5mm):≥140 N

- Puncture Resistance (1.5mm):≥400 N

- Carbon Black Content:0% – 3.0% (for UV stability)

- Hydraulic Conductivity:10−14 to 10−16 cm/s

- Applications:Landfill liners, hazardous waste containment, municipal waste ponds, reservoirs, mining heap leach pads.

1.2 Best Textured HDPE Geomembrane for Slopes: BPM Textured HDPE Geomembrane

Key Features: High friction coefficient, excellent shear strength, high tensile strength, chemical resistance, UV stability, low permeability.

What we like: For projects involving steep slopes or requiring enhanced friction between the geomembrane and adjacent layers (e.g., soil, geotextile, other geomembranes), the BPM Textured HDPE Geomembrane is the undisputed leader. Its roughened surface, achieved through specialized manufacturing processes (e.g., nitrogen-blown or pattern calendering), provides significantly higher interface friction and shear strength compared to smooth liners. This is critical for preventing sliding failures on slopes in applications like landfill cells, mining impoundments, and reservoirs. It maintains all the core benefits of smooth HDPE, including high tensile strength, chemical resistance, and UV stability, while adding this crucial engineering advantage.

What we don’t: The manufacturing process for texturing can sometimes slightly increase the material cost and may require specialized welding techniques for certain textures, though most are still fusion weldable.

Typical Specifications:

- Typical Thicknesses Available:0 mm, 1.5 mm, 2.0 mm, 2.5 mm, 3.0 mm

- Conformance Standard:GRI GM13 (with additional friction testing)

- Asperity Height (Typical):2 to 0.8 mm (for single-sided texture)

- Interface Friction Angle (with typical soil):≥25∘ to 35∘

- Applications:Steep slope liners (landfills, mining, reservoirs), erosion control, base liners with high shear stress requirements.

1.3 Best for Extreme Chemical Resistance: Solmax HDPE Geomembrane

Key Features: Specifically formulated for enhanced chemical compatibility, very low permeability, high stress crack resistance, excellent durability.

What we like: While all HDPE geomembranes offer good chemical resistance, Solmax manufactures specialized HDPE formulations designed for the most aggressive chemical environments. These products are rigorously tested against a wide range of hazardous waste streams and industrial chemicals, often exceeding standard GRI GM13 requirements for chemical compatibility and environmental stress crack resistance (ESCR). This makes them the top choice for highly contaminated sites, industrial process ponds, and hazardous waste landfills where long-term chemical attack is a primary concern. Their commitment to research and development in polymer science for extreme applications is commendable.

Typical Specifications:

- What we don’t:These specialized formulations can come at a premium price point. Ensuring correct chemical compatibility for unique or complex waste streams still requires specific lab testing.

- Typical Thicknesses Available:5 mm, 2.0 mm, 2.5 mm

- Conformance Standard:Exceeds GRI GM13, with additional chemical compatibility testing protocols.

- Environmental Stress Crack Resistance (ESCR – ASTM D5397, 100% Igepal):Often 1000+ hours for specialized resins (vs. 500 hours for standard).

- Oxidative Induction Time (OIT – ASTM D3895):High, ensuring long-term resistance to oxidation by chemicals.

- Applications:Hazardous waste landfills, industrial process ponds, chemical containment facilities, secondary containment for aggressive substances.

1.4 Best for Elevated Temperatures: GSE HDPE Geomembrane

Key Features: High-temperature resistant formulations, excellent long-term durability at elevated temperatures, UV stability, chemical resistance.

What we like: In applications where the geomembrane will be exposed to consistently elevated temperatures (e.g., certain mining processes, power plant ash ponds, or projects in extremely hot climates), standard HDPE can experience accelerated aging. GSE (now part of Solmax) offers specialized HDPE geomembranes engineered to maintain their mechanical and chemical properties even under sustained thermal stress. These products feature enhanced thermal stabilizers and optimized molecular structures to resist thermal oxidation and degradation over extended periods, ensuring long-term integrity in high-temperature environments.

What we don’t: Like specialized chemical-resistant products, these high-temperature formulations will typically have a higher cost per square meter.

Typical Specifications:

- Typical Thicknesses Available:5 mm, 2.0 mm

- Conformance Standard:GRI GM13, with extended high-temperature OIT and thermal aging tests.

- High-Pressure Oxidative Induction Time (HP-OIT – ASTM D5885):Significantly higher values compared to standard HDPE, indicating superior resistance to thermal degradation. (e.g., 500+ minutes vs. 200+ minutes for standard).

- Long-Term Thermal Aging (ASTM D5721):Demonstrated performance after prolonged exposure to elevated temperatures.

- Applications:Mining heap leach pads operating at elevated temperatures, ash ponds, solar ponds, hot water containment.

1.5 Best for Very Large-Scale Projects (Pre-Fabrication): AGRU Sure-Grip HDPE Liner

Key Features: Exceptional factory pre-fabrication capabilities, unique stud design for concrete integration, high quality control, robust material properties.

What we like: For massive projects where minimizing field seams is paramount, AGRU stands out for its ability to produce incredibly large, factory-welded panels of HDPE geomembrane. This drastically reduces installation time, cost, and the potential for field seam failures. While not all projects require their signature Sure-Grip studs for concrete integration, their overall manufacturing quality, consistency, and capacity for large-scale production make them a top choice for projects like large reservoirs, municipal solid waste landfills, and power plant cooling ponds. Their focus on precision manufacturing results in a highly reliable product.

What we don’t: AGRU products are typically at the higher end of the price spectrum. The specific Sure-Grip feature is only relevant if integrating with concrete structures.

Typical Specifications:

- Typical Thicknesses Available:5 mm, 2.0 mm, 2.5 mm

- Conformance Standard:GRI GM13 (and often exceeds it), with specialized factory QC procedures.

- Panel Size:Can be custom pre-fabricated to thousands of square meters, significantly reducing field seaming.

- Applications:Large municipal landfills, vast reservoirs, primary and secondary containment in power plants, industrial facilities requiring minimal field welding.

2. Understanding Best HDPE Geomembrane Specifications & Key Performance Parameters

Choosing the right HDPE geomembrane requires more than just picking a reputable brand. A deep dive into its technical specifications and performance parameters, often governed by industry standards like GRI GM13, is essential.

2.1 GRI GM13: The Industry Benchmark for Best HDPE Geomembranes

GRI GM13 is a widely accepted and rigorous specification developed by the Geosynthetic Research Institute. It outlines the minimum, maximum, and typical average values for various physical, mechanical, and durability properties of HDPE geomembranes. Adherence to GRI GM13 ensures a baseline level of quality and performance. Key parameters covered by GRI GM13 include:

- Thickness:Measured in millimeters (mm) or mils (1 mil = 0.0254 mm). This is a fundamental property affecting strength and durability.

- Density (ASTM D1505):Typically 0.939 to 0.941 g/cm³ (or higher for special formulations). A critical indicator of the polyethylene type.

- Tensile Properties (ASTM D6693):

- Tensile Strength at Yield:The stress at which the material begins to deform permanently.

- Tensile Strength at Break:The maximum stress the material can withstand before breaking.

- Elongation at Yield:The strain at the yield point.

- Elongation at Break:The total strain at the point of rupture. High elongation at break (e.g., >700%) indicates good flexibility and ability to conform to differential settlement.

2.2 Types of Best HDPE Geomembranes: Smooth vs. Textured

The surface finish of an HDPE geomembrane plays a crucial role in its application:

- Smooth HDPE Geomembrane:

- Characteristics:Flat, uniform surface.

- Advantages:Excellent impermeability, lowest hydraulic conductivity, easiest to weld, ideal for flat applications or where slip is desired (e.g., secondary containment beneath primary liner).

- Applications:Base liners for ponds, reservoirs, tunnels, municipal landfills (bottom liner).

- Textured HDPE Geomembrane:

- Characteristics:Roughened surface (either single-sided or double-sided) created during manufacturing (e.g., co-extrusion with nitrogen gas or embossing).

- Advantages:Significantly increased interface friction angle and shear strength, crucial for stability on steep slopes. Prevents sliding between the geomembrane and adjacent soil or geosynthetic layers.

- Applications:Landfill slopes, mining heap leach pad slopes, steep reservoir embankments, critical where stability against sliding is paramount.

2.3 Best HDPE Geomembranes – Welding and Installation: The Foundation of Integrity

Even the highest quality HDPE geomembrane will fail if not properly installed and welded.

- Thermal Fusion Welding:The predominant method for joining HDPE geomembrane sheets. It involves heating the geomembrane edges to their melting point and pressing them together to form a homogeneous bond.

- Hot Wedge Welding:Most common, creates dual tracks with an air channel for non-destructive testing (NDT). Provides fast, strong, and consistent seams.

- Extrusion Welding:Used for repairs, patches, and complex geometries. Molten HDPE resin is extruded into the seam, fusing the sheets.

- Quality Control (QC) and Quality Assurance (QA):

- Non-Destructive Testing (NDT):Air pressure testing (for dual-track welds), vacuum box testing (for extrusion welds), and spark testing are used to verify seam integrity.

- Destructive Testing (DT):Samples are cut from the seams and tested for shear strength and peel adhesion in a lab. This ensures the weld is as strong as or stronger than the parent material.

- Trained Technicians:Welding and testing must be performed by highly experienced and certified technicians.

2.4 Best HDPE Geomembranes – Durability and Lifespan: A Long-Term Investment

HDPE geomembranes are designed for exceptional longevity, often specified for service lives exceeding 100 years in buried applications.

- UV Resistance:Carbon black content and dispersion are crucial for resisting UV degradation in exposed applications.

- Oxidative Resistance:Antioxidants protect the polymer chains from oxidation over time, a process accelerated by heat and certain chemicals. HP-OIT is a key indicator.

- Chemical Resistance:The polymer’s inherent resistance to a broad range of chemicals prevents swelling, dissolution, or degradation.

- Stress Crack Resistance:Resistance to brittle fracture under sustained stress in the presence of certain chemicals.

3. Choosing the Right Best HDPE Geomembranes for Your Project

Selecting the ideal HDPE geomembrane involves a comprehensive assessment of project-specific needs and conditions.

Best HDPE Geomembranes – Application-Specific Requirements:

- Landfills (MSW, Hazardous Waste):

- Bottom Liners:Typically 1.5mm to 2.5mm smooth HDPE for base, with potential for 1.5mm textured on side slopes. Requires excellent chemical resistance, ESCR, and long-term durability. Paired with geotextile protection.

- Caps/Covers:Often 1.0mm to 1.5mm textured HDPE on slopes for stability, 1.0mm smooth on flatter areas. UV stability is critical if exposed.

- Mining (Heap Leach Pads, Tailings Impoundments):

- Liners:5mm to 2.5mm textured HDPE is common for primary and secondary liners due to steep slopes and often hot, aggressive chemical solutions (e.g., cyanide). High temperature and chemical resistance are paramount.

- Overliner/Process Ponds:Often 1.0mm to 1.5mm smooth HDPE.

- Reservoirs & Ponds (Potable Water, Irrigation):

- Thickness Liners:0.2mm to 2.0mm smooth or textured HDPE, depending on slope and subgrade. Non-toxic formulation (if for potable water), UV stability if exposed.

- Wastewater Treatment Lagoons:

- Geomembrane: 0.5mm to 2.5mm smooth or textured HDPE, depending on chemical nature of effluent. Excellent chemical resistance and ESCR are critical.

- Canals & Tunnels:

- Liners:0.75mm to 1.5mm smooth or textured HDPE for waterproofing and seepage control.

- Power Plants (Ash Ponds, Cooling Ponds):

- Liners:0.5mm to 2.5mm smooth or textured HDPE, often requiring high-temperature resistant formulations.

Best HDPE Geomembranes – Site-Specific Considerations:

- Subgrade Conditions:

- Rough/Rocky:Requires thicker geomembrane and robust geotextile protection (e.g., BPM Needled Punched Geotextile) to prevent punctures.

- Smooth/Stable:Allows for thinner geomembrane.

- Differential Settlement:Requires a geomembrane with high elongation at break to accommodate movement without failure (all HDPE excels here, but consider LLDPE for extreme cases).

- Slope Steepness:

- Flat to Moderate Slopes (0-3H:1V):Smooth HDPE can be suitable.

- Steep Slopes (>3H:1V):Textured HDPE is highly recommended to ensure stability and prevent sliding of overlying layers.

- Climate:

- High UV Exposure:Ensure sufficient carbon black content (2.0-3.0%) and UV stabilizers for long-term performance.

- Extreme Temperatures (Hot/Cold):Consider specialized high-temperature resistant formulations if sustained heat is an issue. HDPE generally performs well in cold, but installers must be mindful of flexibility during deployment.

- Chemical Exposure:

- Specific Effluents:Always perform or request chemical compatibility tests for the exact chemicals to be contained, especially for hazardous waste or industrial processes. Solmax and GSE offer specialized chemical-resistant options.

Best HDPE Geomembranes – Budget and Lifecycle Cost:

- Initial Material Cost:Varies by thickness, surface finish (textured is usually slightly more), and specialized formulations (e.g., high-temp, enhanced chemical resistance).

- Installation Cost:Influenced by geomembrane size, number of field seams, site accessibility, and installer experience. Large pre-fabricated panels (e.g., from AGRU) can reduce installation time and cost.

- Long-Term Performance & Maintenance:A higher quality, properly selected and installed HDPE geomembrane will offer a longer service life, reducing future replacement and remediation costs, making it a more cost-effective choice in the long run.

4. Beyond the Geomembrane: Complementary Geosynthetics

A comprehensive containment system often involves more than just a geomembrane. Complementary geosynthetics enhance the performance, extend the life, and ensure the safety of the entire structure.

Geotextiles:

- Protection Geotextiles (e.g., BPM Needled Punched Geotextile Fabric):Placed directly beneath and/or above the geomembrane to prevent punctures from sharp aggregate or other debris. Also provides cushioning and stress distribution. Typically nonwoven, heavy-weight (e.g., 200-800 gsm).

- Filtration Geotextiles (e.g., BPM Continuous Filament Nonwoven Geotextile):Used in drainage layers to prevent fine soil particles from clogging the drainage medium (e.g., gravel, geonet), while allowing water to pass through. Typically nonwoven.

- Separation Geotextiles:Prevents the intermixing of dissimilar soil layers (e.g., preventing clay from contaminating a sand drainage layer). Can be woven or nonwoven.

- Drainage Geotextiles:Facilitate the flow of water within the plane of the geotextile.

Geonets / Geocomposites:

- Geonets:Three-dimensional polymer nets providing high-flow drainage paths for liquids or gases.

- Geocomposites:A combination of two or more geosynthetics (e.g., geonet laminated with geotextiles on one or both sides). They provide both drainage and filtration/protection functions in a single product, simplifying installation and optimizing space. Essential for leachate collection and gas venting systems in landfills.

Geogrids:

- Used for soil reinforcement, providing tensile strength to soil or aggregate layers, particularly in steep slopes or retaining walls, enhancing the stability of the overall structure that supports the geomembrane.

Geocells:

- Three-dimensional cellular confinement systems used for soil stabilization, erosion control, and load distribution on slopes and channels. Can be filled with soil, aggregate, or concrete.

Integrating these geosynthetics effectively is key to a robust and long-lasting containment solution. Manufacturers like BPM Geosynthetics offer a full range of complementary geosynthetics, enabling a complete, engineered solution from a single, reliable source.

5. The Importance of Quality Control and Assurance

For critical containment projects, the quality of the geomembrane, its installation, and the accompanying documentation are paramount.

- Manufacturer’s Quality Control (MQC):This involves rigorous testing at the manufacturing plant to ensure the geomembrane meets specified physical, mechanical, and durability properties (e.g., adherence to GRI GM13). This includes testing raw materials, in-process production samples, and final product rolls.

- Construction Quality Assurance (CQA):This is the oversight performed by independent third-party engineers or technicians during the installation phase. CQA ensures that the geomembrane is installed according to project specifications and industry best practices. Key CQA activities include:

- Subgrade inspection and approval.

- Geomembrane panel deployment verification.

- Field seam preparation and welding parameter monitoring.

- Non-destructive testing (NDT) of all field seams.

- Destructive testing (DT) sampling and laboratory analysis of seam strength.

- Documentation of all activities and test results.

- Proper Documentation:Comprehensive documentation of all materials, testing, and installation procedures is vital for future reference, regulatory compliance, and troubleshooting.

6. Conclusion

The selection of an HDPE geomembrane is a pivotal decision in the success of any containment project. From municipal landfills and hazardous waste sites to vital water reservoirs and complex mining operations, HDPE geomembranes provide the robust, impermeable barrier essential for environmental protection and operational efficiency.

Our in-depth review of the 5 best HDPE geomembranes of 2025, including the versatile BPM Smooth HDPE Geomembrane and the slope-stabilizing BPM Textured HDPE Geomembrane, aims to empower you with the detailed knowledge needed for an informed choice. We’ve highlighted industry leaders like Solmax and GSE for their specialized formulations, and AGRU for its large-scale pre-fabrication capabilities.

By meticulously considering the application type, site conditions, specific chemical exposures, and the long-term performance requirements, coupled with a keen understanding of GRI GM13 standards and rigorous quality control, you can select the optimal HDPE geomembrane. This strategic choice is not merely about material selection; it’s about engineering long-term reliability, ensuring environmental safety, and investing in a sustainable future for your critical infrastructure. Choose wisely, and build with confidence.