High-Density Polyethylene (HDPE) liners, integral to modern containment systems, dominate the global geomembrane market, valued at USD 2.43 billion in 2022 and projected to reach USD 3.69 billion by 2030 at a 5.1% CAGR. Renowned for their durability, chemical resistance, and cost-effectiveness, HDPE liners are widely used in landfills, mining, water management, and aquaculture. The HDPE Liner Cost per m² varies significantly, ranging from $5.38 to $26.91, depending on material quality, thickness, and installation requirements.

This blog post provides a comprehensive, data-driven analysis of HDPE Liner Cost per m2, specifications, installation, and market trends for 2025. It offers detailed insights to assist engineers, project managers, and procurement specialists in budgeting for projects ranging from small agricultural ponds to large-scale industrial containment systems. We explore pricing dynamics, technical parameters, and practical considerations to ensure optimal performance and value.

1. What Is an HDPE Liner?

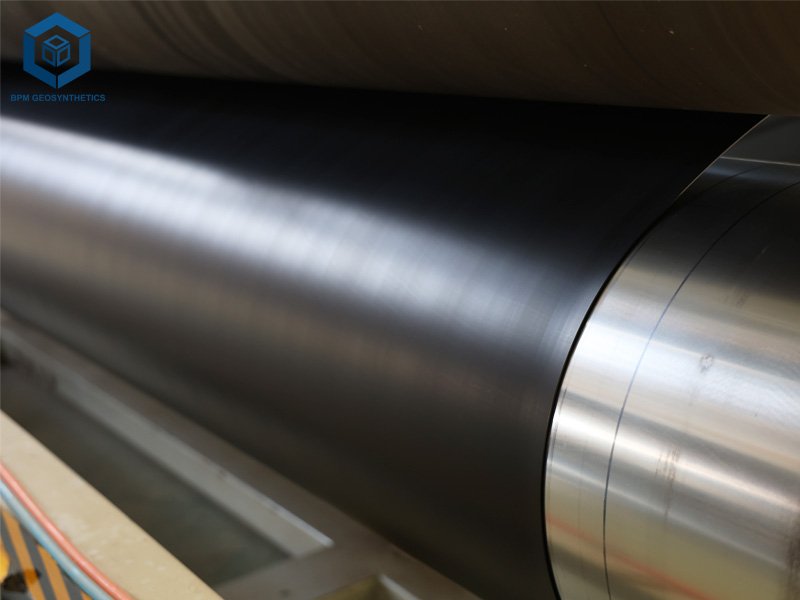

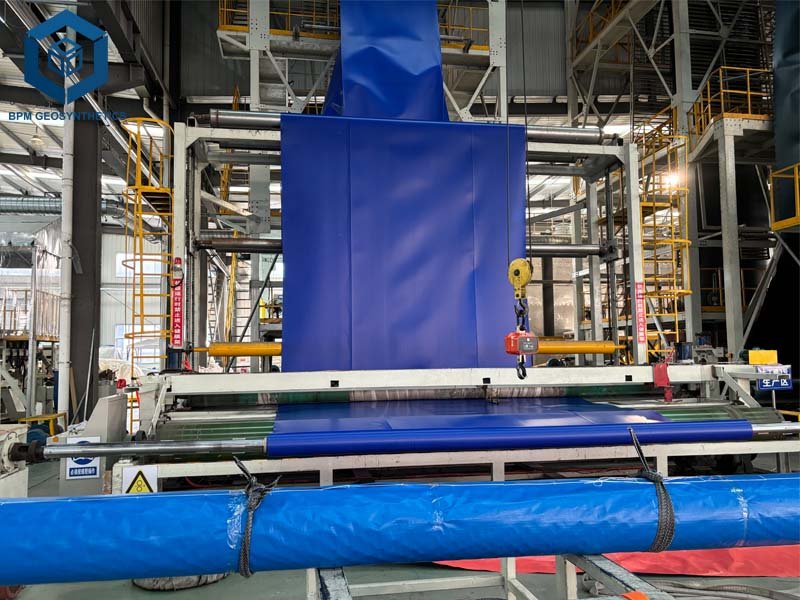

An HDPE liner is a geomembrane made from high-density polyethylene resin, a thermoplastic polymer known for its high strength-to-density ratio, chemical resistance, and impermeability. With a density above 0.94 g/cm³, HDPE liners achieve 99.9% fluid containment, preventing up to 100,000 liters of daily seepage per hectare in landfills or reservoirs. They resist acids, bases, and solvents (pH 2–12), ensuring 20–50-year lifespans in harsh environments. HDPE liners are manufactured via extrusion, producing sheets 3–10 meters wide and 100–150 meters long, typically in thicknesses from 0.5 mm to 3.0 mm.

Key Functions

- Leak Prevention: Reduces groundwater contamination risks by 95% in landfills.

- Water Conservation: Saves 50,000–100,000 liters daily per hectare in reservoirs.

- Chemical Resistance: Withstands corrosive substances, extending project life by 30–50%.

- Environmental Protection: Blocks leachate migration, cutting remediation costs by 40%.

HDPE liners are favored for their low cost, flexibility, and compliance with standards like GRI-GM13, making them ideal for diverse containment applications.

2. Applications of HDPE Liners

HDPE liners serve critical roles across industries, with a 55% market share in geomembrane applications due to their versatility. Key uses include:

Landfill Containment

- Purpose: Prevents leachate from contaminating soil and groundwater.

- Specifications: 1.5–2.0 mm thickness, 800–1,200 N puncture resistance.

- Market Share: 40% of HDPE liner applications, driven by global waste management regulations.

Mining Operations

- Purpose: Contains tailings and process water, preventing environmental leakage.

- Specifications: 1.0–2.5 mm thickness, 30 kN/m tensile strength.

- Market Share: 25% of applications, fueled by USD 2 trillion mining industry growth.

Water Management

- Purpose: Lines reservoirs, canals, and ponds for water retention.

- Specifications: 0.5–1.5 mm thickness, UV-resistant for 20–30 years.

- Market Share: 20% of applications, supporting irrigation and potable water systems.

Aquaculture

- Purpose: Ensures fish-safe, leak-free ponds for fish farming.

- Specifications: 0.5–1.0 mm thickness, non-toxic, GRI-GM13 certified.

- Market Share: 10% of applications, tied to USD 289 billion aquaculture market.

Industrial Containment

- Purpose: Manages wastewater and hazardous liquids in factories.

- Specifications: 1.0–3.0 mm thickness, conductive layers for leak detection.

- Market Share: 5% of applications, growing with industrial regulations.

3. Price Range Breakdown

| Price Bracket | Description | Ideal For |

| $5.38–$8.07/m² | Thin HDPE liners (0.5–0.75 mm), 5–15-year lifespan | Small ponds, low-risk applications |

| $8.07–$16.15/m² | Mid-range HDPE liners (0.75–1.5 mm), 15–30-year lifespan | Landfills, reservoirs, aquaculture |

| $16.15–$26.91/m² | Thick HDPE liners (1.5–3.0 mm), 30–50-year lifespan | Mining, hazardous waste containment |

| $26.91+/m² | Custom HDPE liners with conductive or textured layers | High-risk industrial applications |

- Market Insight: 60% of HDPE liners cost under $16.15/m², with 0.75–1.5 mm liners dominating due to balanced performance.

- Installation Costs: Add $5.38–$32.29/m² for labor, depending on site complexity.

- Bulk Discounts: Orders exceeding 10,000 m² reduce material costs by 15–25%.

4. Key Factors Influencing HDPE Liner Cost per m²

HDPE liner costs are shaped by multiple variables, from raw material prices to project-specific requirements. Below is a detailed analysis for 2025.

4.1 HDPE Liner Cost per m² – Material Quality

- Virgin vs. Recycled Resins: Virgin HDPE costs 20–30% more ($8.07–$10.76/m²) but lasts 50–100 years, compared to 10–20 years for recycled resins ($5.38–$8.07/m²).

- Certifications: GRI-GM13 or ISO 9001 compliance adds $1.08–$3.23/m² for quality assurance.

- Market Trend: 80% of landfill liners use virgin HDPE for 99% chemical resistance.

4.2 HDPE Liner Cost per m² – Thickness

- Range: 0.5–3.0 mm; 0.75–1.5 mm is standard for most applications.

- Cost Impact: Each 0.5 mm increase adds $2.15–$5.38/m² due to higher resin volume.

- Example: A 1.5 mm liner ($10.76/m²) doubles durability vs. 0.75 mm ($6.46/m²).

4.3 HDPE Liner Cost per m² – Project Size and Geometry

- Calculation: Liner size = [Length + (2 × Depth + 1.5 m)] × [Width + (2 × Depth + 1.5 m)].

- Cost Impact: Large projects (10,000+ m²) lower costs by 10–20% via economies of scale.

- Custom Shapes: Irregular geometries increase costs by 15–25% due to fabrication needs.

4.4 HDPE Liner Cost per m² – Site Conditions

- Soil Type: Rocky or sandy soils require geotextile underlayments ($1.08–$5.38/m²), adding 10–20%.

- Slope and Depth: Slopes over 3:1 or depths exceeding 3 m need 1.0–2.0 mm liners, raising costs by $2.15–$6.46/m².

- Preparation: Grading and clearing add $500–$5,000 per project.

4.5 HDPE Liner Cost per m² – Installation Method

- DIY vs. Professional: DIY saves $5.38–$16.15/m² but increases failure risks by 30%.

- Seaming: Heat-welded seams (15 kN/m strength) cost $3.23–$8.61/m² more than adhesive seams.

- Market Trend: 75% of industrial projects use professionals for 98% seam reliability.

4.6 HDPE Liner Cost per m² – Shipping and Logistics

- Cost Impact: Shipping adds $0.54–$2.15/m² for rolls (3–10 m wide, 100–150 m long).

- Regional Variations: Costs in North America and Europe are 10–15% higher than in Asia-Pacific.

- Example: Shipping a 10,000 m² liner costs $1,000–$3,000.

4.7 HDPE Liner Cost per m² – Add-On Features

- UV Resistance: Stabilizers (90% retention after 2,000 hours) add $1.08–$2.69/m².

- Conductive Layers: Enable spark testing, adding $1.61–$4.31/m².

- Textured Surfaces: Improve friction on slopes, adding $2.15–$5.38/m².

5. Material Specifications and Performance Parameters

| Parameter | Specification | Cost Impact |

| Thickness | 0.5–3.0 mm | +$2.15–$5.38 per 0.5 mm |

| Tensile Strength | 27–50 kN/m | +$1.08–$4.31/m² |

| Puncture Resistance | 600–1,500 N | +$1.61–$5.38/m² |

| UV Resistance | 90% retention after 2,000 hours | +$1.08–$2.69/m² |

| Permeability | <10⁻¹³ cm/s | +$2.15–$6.46/m² |

- Tensile Strength: 30 kN/m HDPE withstands 25% more stress than lower-grade liners.

- Puncture Resistance: 800 N liners resist 20% more damage than 600 N liners.

- Lifespan: 1.5 mm liners last 20–50 years, vs. 5–15 years for 0.5 mm liners.

- Weight: 0.9 kg/m² for 1.0 mm liners, impacting shipping costs by 10–15%.

6. Installation Costs and Considerations

Installation accounts for 30–50% of total project costs, ranging from $5.38–$32.29/m². Key steps include:

6.1 HDPE Liner Cost per m² – Site Preparation

- Cost: $500–$5,000 for grading, clearing, and subgrade compaction.

- Geotextile Underlayment: Non-woven geotextile ($1.08–$5.38/m²) prevents 95% of punctures.

- Time: 2–5 days for small projects, 10–20 days for large sites.

6.2 HDPE Liner Cost per m² – Liner Deployment

- Method: Unroll and align liners, avoiding wrinkles (25% failure risk).

- Seaming: Heat welding (98% seam strength) costs $3.23–$8.61/m² vs. adhesive ($1.08–$3.23/m²).

- Labor: Skilled crews charge $2,000–$10,000 for 10,000 m².

6.3 HDPE Liner Cost per m² – Post-Installation

- Anchoring: Trenches or ballast systems add $0.54–$2.15/m².

- Testing: Spark or vacuum testing costs $300–$1,500, ensuring 99% integrity.

- Market Trend: 80% of landfill projects use heat-welded 1.5 mm liners for 30–50-year reliability.

7. How to Choose the Right HDPE Liner

7.1 Budget Under $8.07/m²

- Use: Small ponds, low-risk containment

- Recommendation: 0.5 mm HDPE ($5.38/m²), recycled resins

- Pros: Affordable, 5–15-year lifespan

- Cons: Limited durability, unsuitable for harsh chemicals

7.2 Budget $8.07–$16.15/m²

- Use: Landfills, reservoirs, aquaculture

- Recommendation: 0.75–1.5 mm HDPE ($10.76/m²), virgin resins

- Pros: 15–30-year lifespan, chemical-resistant

- Cons: Higher installation costs

7.3 Budget $16.15–$26.91/m²

- Use: Mining, hazardous waste containment

- Recommendation: 1.5–3.0 mm HDPE ($21.53/m²), conductive layers

- Pros: 30–50-year lifespan, high performance

- Cons: Significant upfront investment

7.4 Key Considerations

- Project Scale: Use calculators for accurate sizing.

- Environmental Conditions: Select UV-resistant liners for exposed sites.

- Site Preparation: Rocky soils need thicker liners or geotextiles.

- Compliance: Ensure GRI-GM13 or ASTM D7466 certification.

8. Conclusion

HDPE liners, commanding 55% of the USD 2.43 billion geomembrane market, cost $5.38–$26.91/m², with 0.75–1.5 mm liners leading due to their 15–30-year lifespan and 99.9% impermeability. Costs are driven by thickness, resin quality, project size, and installation (30–50% of expenses), with bulk orders saving 15–25%. Trends like recycled resins, automated seaming, and smart liners shape 2025’s market, emphasizing sustainability and efficiency. Whether for a 5,000 m² aquaculture pond or a 50,000 m² landfill, prioritize chemical resistance, durability, and compliance to maximize value and ensure long-term performance.

Contact BPM Geomembrane for samples and quotes to ensure a leak-proof, durable project.