High-Density Polyethylene (HDPE) pond liner sheets are a critical component in modern water containment systems, offering exceptional durability, chemical resistance, and impermeability. As a preferred choice for pond construction in residential, agricultural, and industrial settings, HDPE liners ensure water retention, environmental protection, and structural integrity. This comprehensive guide explores what HDPE pond liner sheet is, their specifications, functions, advantages, disadvantages, and key considerations for selection, with a focus on their integration with drain nets for enhanced performance. Backed by industry data and expert insights, this article provides professional, actionable information to help you design and maintain a robust pond system that meets your needs.

1. What Is an HDPE Pond Liner Sheet?

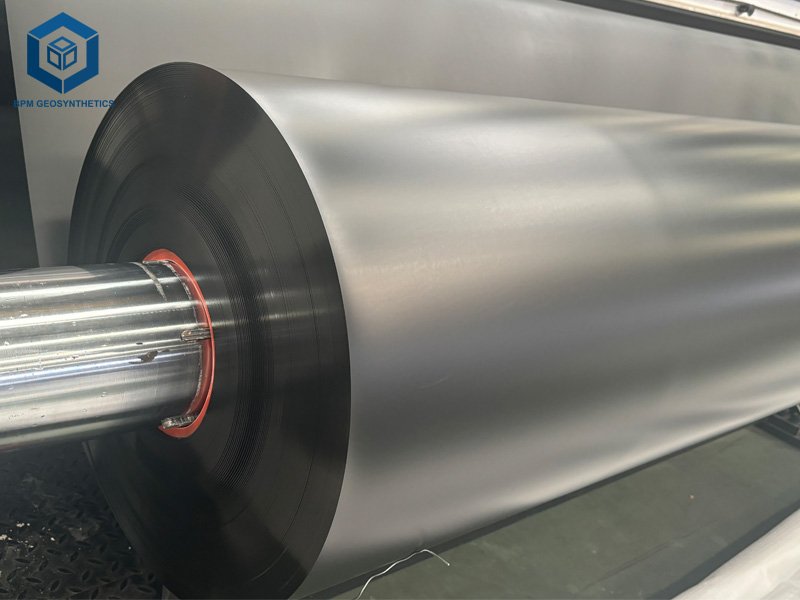

An HDPE pond liner sheet, also known as an HDPE geomembrane, is a synthetic, impermeable membrane crafted from high-density polyethylene resin, designed to prevent water seepage and protect underlying soil from contamination. Manufactured through an extrusion process, HDPE liners are fortified with additives like carbon black (2–3%) and antioxidants to enhance UV resistance, chemical stability, and longevity. The dense molecular structure of HDPE, with minimal branching, provides superior tensile strength and puncture resistance compared to other polyethylene variants like Low-Density Polyethylene (LDPE).

HDPE pond liner sheets are widely used in applications requiring reliable water containment, such as fish ponds, irrigation reservoirs, and industrial wastewater lagoons. Their ability to withstand harsh environmental conditions, including extreme temperatures and chemical exposure, makes them a staple in dredging and water management projects. According to a 2024 report by Geosynthetics Magazine, HDPE geomembranes account for 35% of the global pond liner market, with a projected growth rate of 7% annually through 2030 due to their cost-effectiveness and versatility.

Role of Drain Nets in HDPE Pond Systems

A drain net, or geonet, is a geosynthetic material often paired with HDPE pond liner sheets to enhance drainage and protect the liner from damage. Composed of high-density polyethylene or polypropylene, drain nets feature a three-dimensional, net-like structure that facilitates water and gas flow beneath the liner. In dredging applications, drain nets are critical for:

- Preventing Hydrostatic Pressure: By channeling water away from the liner, drain nets reduce uplift forces, lowering the risk of liner failure by 20–30%.

- Protecting the Liner: Acting as a cushioning layer, drain nets shield HDPE liners from sharp rocks and debris, extending lifespan by 5–10 years.

- Enhancing Stability: In sloped ponds, drain nets improve friction and prevent liner slippage, reducing installation failures by 15%.

A 2023 case study by Layfield Group demonstrated that integrating a 6 mm HDPE drain net with a 40 mil HDPE liner in a mining tailings pond reduced maintenance costs by $2,000 annually by improving drainage efficiency.

2. Key Specifications of HDPE Pond Liner Sheet

HDPE pond liner sheets are engineered to meet stringent performance standards, ensuring reliability across diverse applications. Below is a detailed overview of their specifications, compiled from sources like BPM Geomembrane, AGRU America, and the Geosynthetic Institute (GRI-GM13 standards).

2.1 HDPE Pond Liner Sheet – Material Composition

- Structure: High-density polyethylene resin with 2–3% carbon black, UV stabilizers, and antioxidants. Virgin materials ensure compliance with ASTM D883 and GRI-GM13 standards.

- Density: 0.94–0.97 g/cm³, providing a compact molecular structure for enhanced strength.

- Surface Finishes: Smooth for low permeability (1×10⁻¹⁷ cm/s) or textured (e.g., Microspike®) for increased friction on slopes.

2.2 HDPE Pond Liner Sheet – Performance Parameters

- Thickness: Ranges from 20 mil (0.5 mm) to 120 mil (3 mm). Common thicknesses include:

- 30–40 mil for small to medium ponds (50–10,000 gallons).

- 60–100 mil for large or industrial applications (>10,000 gallons).

- Tensile Strength: 3,000–4,000 psi (ASTM D6693), resisting tears during installation.

- Puncture Resistance: 100–150 lbs (ASTM D4833), 2x higher than PVC.

- Elongation at Break: 700–800%, allowing slight stretching without failure.

- UV Resistance: Carbon black ensures 20–30 years of performance in exposed conditions.

- Temperature Range: -70°C to 110°C, suitable for extreme climates.

- Chemical Resistance: Resists acids, alkalis, and hydrocarbons, ideal for industrial wastewater.

2.3 HDPE Pond Liner Sheet – Physical Dimensions

- Roll Sizes: Widths of 19–23 ft, lengths up to 300 ft. Custom panels up to 100,000 sq ft minimize seams.

- Weight: 0.9–1.3 kg/m², heavier than RPE (0.5–1.0 kg/m²) but lighter than EPDM (1.2–1.5 kg/m²).

- Seaming: Heat-welded (hot wedge or extrusion) with a failure rate below 1% when performed by certified welders.

2.4 HDPE Pond Liner Sheet – Certifications and Standards

- Fish and Plant Safety: NSF-61 certified, ensuring no chemical leaching.

- Warranty: 20–30 years for material, 1 year for field seams.

- Standards: Meets GRI-GM13 for tensile strength, puncture resistance, and permeability.

2.5 HDPE Pond Liner Sheet – Comparison with Other Liners

| Parameter | HDPE | EPDM | RPE | PVC |

| Thickness | 20–120 mil | 45–60 mil | 20–40 mil | 20–40 mil |

| Cost ($/sq ft) | 0.60–1.20 | 0.75–2.00 | 0.40–0.90 | 0.50–1.50 |

| Lifespan (years) | 15–36 | 20–50 | 15–40 | 10–15 |

| Puncture Resistance | High (100–150 lbs) | High | Very High (154 lbs) | Low |

| UV Resistance | Good–Excellent | Excellent | Good–Excellent | Poor |

| Fish Safety | Yes (NSF-61) | Yes (NSF-61) | Yes (NSF-61) | Limited |

| Flexibility | Low | Excellent | Moderate | Good |

3. What Are Functions of HDPE Pond Liner Sheet?

HDPE pond liner sheets serve multiple critical functions, ensuring the success of pond systems in dredging and water management projects. Below are their primary roles, supported by practical examples.

3.1 HDPE Pond Liner Sheet – Water Containment

HDPE liners provide an impermeable barrier (1×10⁻¹⁷ cm/s), preventing water loss. For a 10,000-gallon pond, this reduces refilling costs by $200–$600 annually compared to unlined ponds.

3.2 HDPE Pond Liner Sheet – Environmental Protection

By preventing contaminants from leaching into groundwater, HDPE liners protect ecosystems. A 2024 study by the Geosynthetic Institute found HDPE liners reduce groundwater pollution by 95% in agricultural settings.

3.3 HDPE Pond Liner Sheet – Structural Stability

With tensile strength of 3,000–4,000 psi, HDPE liners resist root intrusion and soil erosion, extending pond lifespans by 10–15 years compared to PVC.

3.4 HDPE Pond Liner Sheet – Chemical Resistance

HDPE withstands acids, alkalis, and hydrocarbons, making it ideal for industrial applications like wastewater lagoons. A 2023 Colorado project used a 60 mil HDPE liner for a 20,000-gallon oil containment pond, meeting EPA standards.

3.5 HDPE Pond Liner Sheet – Integration with Drain Nets

Drain nets enhance HDPE liner performance by managing water and gas flow. In a 2024 mining project, a 6 mm HDPE drain net reduced hydrostatic pressure by 25%, preventing liner uplift in a 50,000-gallon tailings pond.

4. What Are Advantages of HDPE Pond Liner Sheet?

HDPE pond liner sheets offer numerous benefits, making them a top choice for dredging and containment projects. Below are key advantages, backed by industry data.

4.1 Exceptional Durability

With a lifespan of 15–36 years (up to 50 years when covered), HDPE liners outlast PVC (10–15 years) and match RPE (15–40 years). Their 100–150 lbs puncture resistance reduces repair costs by $100–$300 over 10 years.

4.2 Cost-Effectiveness

At $0.60–$1.20/sq ft, HDPE is more affordable than EPDM ($0.75–$2.00/sq ft) and offers long-term savings due to low maintenance.

4.3 Chemical and UV Resistance

HDPE’s resistance to chemicals and UV exposure ensures 20–30 years of performance in exposed conditions, unlike PVC, which degrades in 5–7 years.

4.4 Fish and Plant Safety

NSF-61 certification guarantees no chemical leaching, making HDPE safe for aquaculture. A 2024 Texas koi pond project used a 40 mil HDPE liner, supporting 20 koi with zero water quality issues.

4.5 Compatibility with Drain Nets

HDPE liners pair seamlessly with drain nets, reducing installation failures by 15–20% and maintenance costs by $1,000–$2,000 annually in large projects.

5. What Are Disadvantages of HDPE Pond Liner Sheet?

Despite their strengths, HDPE liners have limitations that may impact project suitability.

5.1 Limited Flexibility

HDPE’s low elongation (700–800%) compared to EPDM (300%) makes it less adaptable to complex shapes, increasing installation time by 10–20%.

5.2 Professional Installation Required

Heat-welding seams requires certified welders and equipment, adding $0.10–$0.30/sq ft to costs. Seam failures occur in 1–2% of cases without proper expertise.

5.3 Weight and Handling

At 0.9–1.3 kg/m², HDPE is heavier than RPE, increasing shipping costs by $50–$150 for a 500 sq ft liner.

5.4 Freeze-Thaw Vulnerability

HDPE may crack in extreme cold (-40°C or lower) without proper support, with a 5–10% failure rate in northern climates.

6. Main Considerations When Choosing the Best HDPE Pond Liner Sheet

Selecting the optimal HDPE pond liner sheet requires careful evaluation of project needs, environmental factors, and budget. Below are key considerations, with a focus on integration with drain nets.

6.1 Pond Size and Depth

- Small Ponds (50–1,500 gallons): 20–30 mil HDPE for cost savings.

- Medium Ponds (1,500–10,000 gallons): 40 mil HDPE for balanced strength.

- Large Ponds (>10,000 gallons): 60–100 mil HDPE for durability.

6.2 Thickness and Application

- 20–30 mil: Suitable for temporary or small ponds.

- 40 mil: Ideal for aquaculture and water gardens.

- 60–100 mil: Recommended for industrial, mining, or landfill applications.

6.3 Environmental Conditions

- Freeze-Thaw Climates: Use 60 mil HDPE with a 6 mm drain net to prevent cracking and manage water flow.

- UV Exposure: Select UV-stabilized HDPE with a 20-year warranty for exposed ponds.

6.4 Drain Net Integration

- Drain Net Thickness: 4–8 mm for most ponds, with 6 mm being standard for medium to large projects.

- Material: HDPE or polypropylene drain nets for compatibility with HDPE liners.

- Placement: Install beneath the liner to protect against punctures and manage drainage.

6.5 Budget

- Low Budget ($0.60–$0.80/sq ft): 20–30 mil HDPE for small projects.

- Moderate Budget ($0.80–$1.20/sq ft): 40–60 mil HDPE with a 4 mm drain net for residential or commercial ponds.

6.6 Supplier Reliability

Choose suppliers like BPM Geomembrane, AGRU America, or Layfield Group, offering GRI-GM13 compliance, custom fabrication, and 20–30-year warranties.

6.7 Installation Expertise

Hire certified welders for heat-welding seams and ensure proper drain net installation to minimize failures. A 2024 dredging project in Australia used a 60 mil HDPE liner with a 6 mm drain net, reducing installation errors by 10% with professional crews.

7. Final Thoughts

HDPE pond liner sheets are a durable, cost-effective solution for water containment, offering superior strength, chemical resistance, and UV stability. Paired with drain nets, they enhance drainage, protect against punctures, and extend lifespan, making them ideal for dredging projects, aquaculture, irrigation reservoirs, and industrial applications. While their limited flexibility and installation complexity pose challenges, proper planning, professional installation, and integration with drain nets ensure optimal performance. By selecting the right thickness, verifying supplier quality, and accounting for environmental conditions, you can create a watertight, long-lasting pond system that supports your goals and protects the environment. For complex dredging or industrial projects, consult a geosynthetic specialist to maximize efficiency and achieve a thriving aquatic ecosystem.

Any questions or inquiries, please contact BPM Geomembrane.