Root barriers are essential tools in modern landscaping, civil engineering, and urban planning, designed to manage and redirect the growth of tree and plant roots to prevent damage to infrastructure, landscapes, and utilities. With the global geomembrane market, including root barriers, valued at $2.57 billion in 2024 and projected to grow at an 8.6% CAGR to $4.24 billion by 2030, their importance in sustainable development is undeniable. Root barriers protect sidewalks, foundations, pipelines, and pavements from invasive roots, which can cause costly repairs—estimated at $4,000–$10,000 for foundation damage in the U.S. alone. In regions like Kenya, where urban expansion and agriculture intersect, root barrier is critical for controlling invasive species like bamboo and Japanese knotweed.

This ultimate guide explores the definition, features, types, specifications, life expectancy, and considerations for choosing root barrier, providing detailed insights to help homeowners, contractors, and arborists make informed decisions.

1. What Is A Root Barrier?

A root barrier is a physical or chemical barrier installed underground to redirect or inhibit the growth of tree or plant roots, preventing them from damaging nearby structures such as sidewalks, driveways, foundations, and utility lines. By guiding roots downward or containing their spread, root barriers protect infrastructure while preserving the health of trees and plants. They are commonly used in urban landscaping, residential properties, and commercial projects to mitigate risks like cracked pavements (costing $1,500–$5,000 to repair) and foundation settlement caused by soil moisture depletion.

Root barriers work by creating an impermeable or semi-permeable boundary that roots cannot penetrate, forcing them to grow deeper or in a controlled direction. They are particularly effective for aggressive species like bamboo, which can grow 2–3 feet per day, or trees with expansive root systems, such as oaks and pecans, which can extend 2–3 times the canopy width. According to the International Society of Arboriculture, root barriers reduce infrastructure damage by up to 90% when properly installed.

Why Use Root Barriers?

- Infrastructure Protection: Prevents roots from lifting sidewalks, cracking foundations, or invading sewer lines, saving 50–70% on repair costs.

- Tree Health: Encourages deeper root growth, improving tree stability and access to groundwater.

- Environmental Benefits: Reduces the need for chemical herbicides, promoting eco-friendly landscaping.

- Invasive Species Control: Contains aggressive plants like bamboo or Japanese knotweed, which can spread 10–20 feet underground.

Common Applications

- Urban Landscaping: Protects sidewalks, curbs, and roads in cityscapes, where 60% of tree-related damage occurs.

- Residential Properties: Safeguards foundations, driveways, and pools from root intrusion.

- Agriculture: Controls root spread in orchards and farms, reducing competition for water and nutrients.

- Green Roofs: Prevents root penetration into waterproofing membranes, extending roof lifespan by 20–30%.

2. Key Features of Root Barrier

Root barriers are engineered with specific features to ensure durability, functionality, and environmental compatibility. Below are the critical attributes that define high-quality root barriers, based on 2025 industry standards:

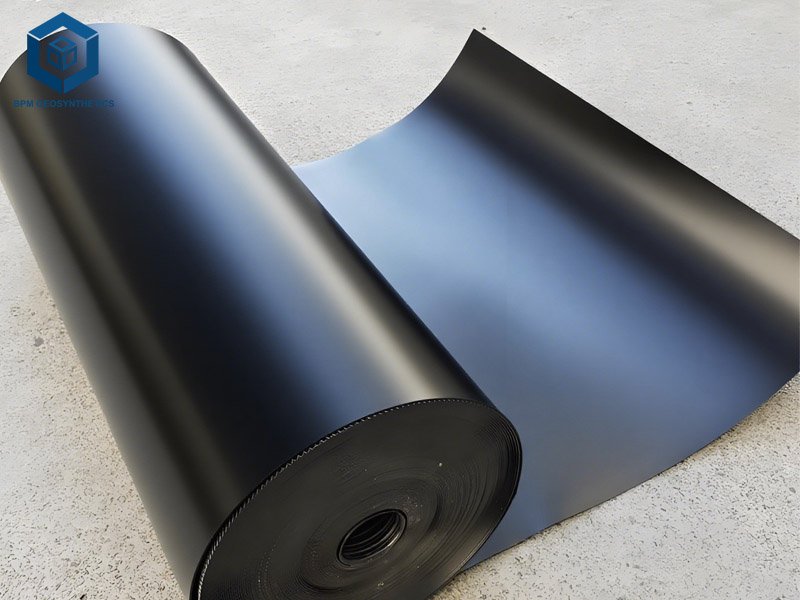

2.1 Root Barrier – Material Composition

- High-Density Polyethylene (HDPE): Accounts for 47% of root barrier materials due to its durability, flexibility, and UV resistance. Offers tensile strength of 15–20 MPa (ASTM D6693) and puncture resistance of 2,000–4,409 N (ASTM D4833).

- Polypropylene (PP): Lightweight and recyclable, with tensile strength of 10–15 MPa, used in woven and non-woven barriers.

- Low-Density Polyethylene (LDPE): Flexible and cost-effective, used in triple-coated barriers like Root Barrier C3, with a puncture resistance of 4,409 N.

- Chemical Barriers: Incorporate herbicides like trifluralin, creating a root-repellent zone effective for 15–20 years.

- Natural Materials: Jute or coir for temporary, biodegradable barriers, suitable for erosion control but with lower durability (2–5 years).

2.2 Root Barrier – Thickness

- 40–60 mil (1.0–1.5 mm): Common for residential applications, offering sufficient strength for small to medium trees.

- 80–100 mil (2.0–2.5 mm): Used for commercial projects or aggressive species, providing superior puncture resistance.

- Custom Thickness: Up to 120 mil for heavy-duty applications like Japanese knotweed containment.

2.3 Root Barrier – Design Features

- Ribbed Surfaces: Vertical ribs (90° flared) guide roots downward, reducing circling by 80%.

- Seam Strength: Continuous rolls (80–100 ft) minimize seams, reducing root intrusion risk by 95% compared to panel-style barriers.

- UV Stabilization: Extends lifespan by 20–30% in exposed conditions, with 5–10 years of UV resistance for HDPE.

- Permeability Options: Non-permeable barriers (HDPE) block water and roots, while permeable barriers (geotextiles) allow water passage for specific applications.

2.4 Root Barrier – Dimensions

- Widths: 12–48 inches (30–122 cm), with 24 inches standard for most applications.

- Lengths: Rolls up to 100–780 ft, reducing seams and installation time by 15%.

- Depth: 12–48 inches, depending on tree species and soil conditions, with 24–36 inches common for urban trees.

2.5 Root Barrier – Certifications

- ISO 9001 and CE: Ensure quality and durability, with CE1214-CPD-4688 for HDPE barriers.

- NSF/ANSI 61: Confirms safety for applications near water systems or edible plants.

- FLL Compliance: Meets German green roof standards for root penetration resistance.

These features make root barriers versatile, durable, and adaptable to various environments, from urban sidewalks to rural farms.

3. What Are Types of Root Barrier?

Root barriers are classified based on their material, permeability, and installation method. Below are the primary types available in 2025:

3.1 Root Barrier – Physical Barriers

Physical barriers redirect roots without harming the plant, making them the most eco-friendly option. They account for 80% of the market due to their versatility and durability.

- HDPE Barriers: HDPE root barrier – High-strength, non-permeable barriers with 80–100 mil thickness, ideal for aggressive roots like bamboo. Cost: $0.50–$2.00 per square foot.

- Polypropylene Barriers: Woven or non-woven, used for lighter applications like garden beds. Cost: $0.30–$1.00 per square foot.

- LDPE Barriers: Flexible, triple-coated options like Root Barrier C3, used for Japanese knotweed containment. Cost: $0.40–$1.50 per square foot.

- Metal Barriers: Stainless steel or aluminum for high-strength applications, costing $2.00–$5.00 per square foot but prone to corrosion over time.

3.2 Root Barrier – Chemical Barriers

Chemical barriers use herbicides like trifluralin embedded in geotextile fabric to deter root growth. They are effective for 15–20 years but may affect surrounding ecosystems if not carefully managed.

- Typar Biobarrier: Combines geotextile with trifluralin nodules, creating a root-free zone. Cost: $1.00–$3.00 per square foot.

- Applications: Best for non-edible plant areas due to chemical release, used in 10% of commercial projects.

3.3 Root Barrier – Permeable vs. Non-Permeable Barriers

- Non-Permeable: HDPE or LDPE barriers block water and roots, ideal for foundations and utilities. Cost: $0.50–$2.00 per square foot.

- Permeable: Geotextile barriers with copper foil or woven fabrics allow water passage while blocking roots, used in drainage-sensitive areas. Cost: $0.30–$1.50 per square foot.

3.4 Root Barrier – Installation Configurations

- Linear Barriers: Installed along sidewalks or driveways to protect linear infrastructure. Depth: 18–36 inches.

- Surround Barriers: Encircle tree root balls to contain growth in all directions, ideal for urban tree pits. Depth: 24–48 inches.

- Root Pruning Barriers: Used to redirect existing roots, requiring professional installation to avoid tree stress. Cost: $1.00–$2.50 per square foot.

4. Key Differences of Types Of Root Barrier

Understanding the differences between root barrier types is crucial for selecting the right solution. Below is a detailed comparison based on material, application, cost, and performance:

| Type | Material | Permeability | Cost ($/sq ft) | Applications | Strength (N) | Lifespan (Years) |

| HDPE | High-Density Polyethylene | Non-Permeable | 0.50–2.00 | Foundations, sidewalks, bamboo | 2,000–4,409 | 50–100 |

| Polypropylene | Woven/Non-Woven PP | Permeable/Non-Permeable | 0.30–1.00 | Garden beds, light infrastructure | 1,000–2,000 | 20–50 |

| LDPE | Low-Density Polyethylene | Non-Permeable | 0.40–1.50 | Japanese knotweed, tree pits | 4,409 | 50–100 |

| Chemical (Trifluralin) | Geotextile + Herbicide | Permeable | 1.00–3.00 | Non-edible plant areas | 1,000–2,000 | 15–20 |

| Metal | Stainless Steel/Aluminum | Non-Permeable | 2.00–5.00 | Heavy-duty, industrial applications | 5,000+ | 20–50 |

Key Differences

- Durability: HDPE and LDPE offer the longest lifespans (50–100 years) due to UV stabilization and high puncture resistance. Chemical barriers last 15–20 years due to herbicide depletion.

- Cost: Polypropylene is the most affordable ($0.30–$1.00 per square foot), while metal barriers are the most expensive ($2.00–$5.00 per square foot).

- Environmental Impact: Chemical barriers risk ecosystem disruption, while HDPE and polypropylene are recyclable and eco-friendly.

- Installation Complexity: Permeable barriers require less precise sealing, reducing labor costs by 10–15% compared to non-permeable HDPE.

- Applications: HDPE and LDPE are versatile for aggressive roots, while chemical barriers are niche for specific commercial uses.

5. Main Considerations When Choosing Best Root Barrier

Selecting the right root barrier requires careful evaluation of project needs, tree species, and environmental conditions. Below are the key considerations to ensure optimal performance:

Tree Species and Root Behavior

- Aggressive Roots: Species like bamboo, willows, and poplars require deep (36–48 inches) HDPE or LDPE barriers with 80–100 mil thickness.

- Shallow Roots: Ornamental trees like maples or cherries need 12–18 inch barriers, saving 20–30% on material costs.

- Tap Roots: Pecan trees with deep tap roots require barriers extending to 30–36 inches to prevent soil drying under foundations.

Soil and Environmental Conditions

- Expansive Clay Soils: Non-permeable HDPE barriers retain moisture, reducing differential settlement by 80%.

- Sandy Soils: Permeable geotextiles allow drainage while controlling roots, ideal for coastal areas.

- UV Exposure: UV-stabilized HDPE or LDPE barriers are essential for partially exposed installations, lasting 5–10 years above ground.

Installation Requirements

- Depth and Width: Barriers should extend 2–3 feet beyond the tree’s drip line and 1–2 inches above ground to prevent root overgrowth.

- Seam Integrity: Continuous rolls (100 ft) reduce seam failures by 95% compared to panel-style barriers.

- Professional Installation: Required for chemical barriers and deep installations (>36 inches), costing $1.00–$2.50 per square foot.

Budget Constraints

- Low Budget: Polypropylene or lightweight HDPE (40–60 mil) at $0.30–$1.00 per square foot for small projects.

- High Budget: Heavy-duty HDPE (80–100 mil) or metal barriers for commercial or invasive species control, costing $1.50–$5.00 per square foot.

Regulatory and Safety Considerations

- Certifications: Choose ISO 9001 or FLL-compliant barriers for quality assurance.

- Environmental Safety: Avoid chemical barriers near edible plants or water sources to prevent contamination.

- Local Regulations: Check municipal codes for urban installations, as some cities mandate specific barrier depths.

Project Scale and Application

- Residential: 12–24 inch HDPE barriers for driveways and foundations, costing $500–$2,000 for 100 linear feet.

- Commercial: 36–48 inch HDPE or LDPE barriers for tree pits and sidewalks, costing $5,000–$20,000 for large projects.

Consulting an arborist or invasive species expert ensures the barrier matches the tree species and site conditions, reducing failure risk by 90%.

6. What is Life Expectancy of Root Barrier?

The life expectancy of root barriers depends on material, installation quality, and environmental conditions. Below are the lifespans based on 2025 data:

- HDPE Barriers: 50–100 years when buried in natural soils (pH 4–9, <25°C), with UV-stabilized options lasting 5–10 years above ground.

- LDPE Barriers: 50–100 years in buried conditions, with triple-coated options like Root Barrier C3 offering 50+ years for invasive species control.

- Polypropylene Barriers: 20–50 years, with woven options lasting longer than non-woven due to higher tensile strength.

- Chemical Barriers: 15–20 years, limited by herbicide depletion (e.g., trifluralin in Typar Biobarrier).

- Metal Barriers: 20–50 years, reduced by potential corrosion in acidic soils (pH <4).

- Natural Barriers (Jute/Coir): 2–5 years, biodegradable and suitable for temporary erosion control.

Factors Affecting Lifespan

- Soil Conditions: Acidic soils (pH <4) reduce metal barrier lifespan by 20–30%, while neutral soils (pH 4–9) maximize HDPE durability.

- UV Exposure: Non-UV-stabilized barriers degrade 50% faster above ground, lasting 2–5 years.

- Installation Quality: Proper seam sealing and geotextile underlayment extend lifespan by 20–30%.

- Maintenance: Annual inspections and repairs for tears or shifts increase lifespan by 10–15%.

Maintenance Tips for Longevity

- Inspect Annually: Check for root intrusion or barrier shifts, costing $0.01–$0.05 per square foot.

- Protect Seams: Use HDPE sealant tape or welding to reinforce overlaps, reducing failure risk by 95%.

- Geotextile Underlayment: Adds a protective layer, costing $0.30–$1.50 per square foot, to prevent punctures.

- Monitor Tree Growth: Adjust barrier depth for aggressive species if roots grow beyond initial projections.

With proper installation and maintenance, HDPE and LDPE barriers can last over a century, offering long-term value for infrastructure protection.

7. Final Thoughts

Root barriers are a critical investment for protecting infrastructure and landscapes from invasive roots, with costs ranging from $0.30–$5.00 per square foot depending on material and application. HDPE and LDPE barriers offer the longest lifespans (50–100 years) and highest durability, making them ideal for aggressive species and urban projects. By understanding key features, types, and installation considerations, you can select a barrier that balances cost, performance, and environmental impact. Proper installation, maintenance, and supplier selection ensure long-term protection, saving 50–70% on repair costs.

Contact BPM Geomembrane for tailored solutions to safeguard your property in 2025 and beyond.