High-Density Polyethylene (HDPE) geomembrana, also known as HDPE geomembrane, is a premier geosynthetic material designed for impermeable containment in environmental, civil, and industrial applications. Valued at USD 2.1 billion in 2024, the global geomembrane market is projected to grow at a CAGR of 5.8% through 2030, with HDPE geomembranes holding a 60% share due to their exceptional durability, chemical resistance, and cost-effectiveness (Technavio, 2024). BPM Geosynthetics, a leading manufacturer, reports that Geomembrana in HDPE is the material of choice for 70% of containment projects worldwide, from landfills to aquaculture.

This guide delves into the definition, properties, specifications, applications, installation, and emerging trends of HDPE geomembrana, offering engineers, contractors, and project managers comprehensive insights to drive informed decisions.

1. What Is Geomembrana in HDPE?

Definition of Geomembrana in HDPE

Geomembrana in HDPE, also known as HDPE geomembrana, is a synthetic, low-permeability liner crafted from high-density polyethylene resin, a thermoplastic polymer with a density range of 0.940–0.965 g/cm³. It functions as a robust barrier to prevent the migration of liquids, gases, or contaminants in geotechnical and environmental projects. Compared to other geomembranes like PVC or LLDPE, HDPE geomembrana offers superior tensile strength and chemical inertness, making it ideal for high-risk containment. BPM Geosynthetics uses 100% virgin HDPE resin, blended with 2–3% carbon black, antioxidants, and UV stabilizers to ensure a service life of up to 50 years.

How Is Geomembrana in HDPE Made?

The manufacturing process of HDPE geomembrana ensures precision and durability, adhering to ASTM D5199 and GRI-GM13 standards. Key steps include:

- Resin Mixing: Virgin HDPE resin is combined with additives like carbon black (UV resistance), antioxidants, and stabilizers.

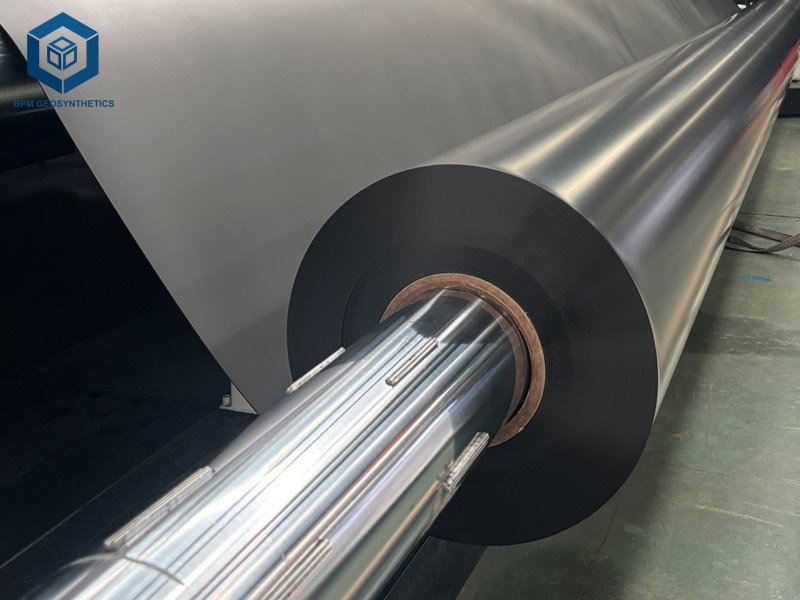

- Extrusion: The mixture is melted and extruded into a continuous sheet, typically 0.5–3.0 mm thick, using blown film or flat die extrusion.

- Cooling and Sizing: The sheet is cooled, trimmed to widths of 4–10 meters, and rolled into lengths up to 100 meters.

- Texturing (Optional): Nitrogen gas or embossing creates textured surfaces for enhanced friction on slopes.

BPM Geosynthetics reports a thickness tolerance of ±3%, ensuring consistent performance across applications.

Key Properties of Geomembrana in HDPE

HDPE geomembrana’s effectiveness is rooted in its material properties, validated by industry-standard testing:

- Chemical Resistance: Resists acids, alkalis, and solvents, suitable for pH 2–12 environments (ASTM D5322).

- Impermeability: Permeability coefficient <1×10⁻¹³ cm/s, blocking 99.9% of fluid migration (ASTM D5887).

- UV Resistance: Carbon black ensures 90% strength retention after 1600 hours of UV exposure (ASTM D7238).

- Tensile Strength: 15–35 MPa, enduring mechanical stress (ASTM D6693).

- Puncture Resistance: ≥500 N for 1.5 mm thickness, ideal for rocky subgrades (ASTM D4833).

- Temperature Range: Performs reliably from -50°C to 80°C, per ASTM D746.

- Stress Crack Resistance: ≥500 hours, ensuring long-term integrity (ASTM D5397).

These attributes position HDPE geomembrana as the leading choice for 65% of environmental containment projects, per the Geosynthetic Institute.

2. Technical Specifications of Geomembrana in HDPE

Standard Sizes and Thicknesses

HDPE geomembrana is available in a range of sizes and thicknesses to meet diverse project requirements:

- Thickness: 0.5 mm, 0.75 mm, 1.0 mm, 1.5 mm, 2.0 mm, 3.0 mm (20–120 mils).

- Width: 4–10 meters, with 6–8 meters as standard.

- Length: 50–100 meters per roll, customizable up to 200 meters.

- Colors: Black (default), green (municipal projects), white (biogas), blue (aquaculture).

Performance Parameters

The following table outlines key specifications for 1.0 mm and 2.0 mm HDPE geomembrana, based on GRI-GM13 standards:

| Parameter | 1.0 mm HDPE | 2.0 mm HDPE | Test Standard |

| Tensile Strength (MPa) | ≥17 | ≥30 | ASTM D6693 |

| Elongation at Break (%) | ≥700 | ≥700 | ASTM D6693 |

| Puncture Resistance (N) | ≥320 | ≥640 | ASTM D4833 |

| Stress Crack Resistance (hrs) | ≥500 | ≥500 | ASTM D5397 |

| Permeability (cm/s) | <1×10⁻¹³ | <1×10⁻¹³ | ASTM D5887 |

| UV Resistance (% retained) | ≥90 after 1600 hrs | ≥90 after 1600 hrs | ASTM D7238 |

| Carbon Black Content (%) | 2–3 | 2–3 | ASTM D1603 |

Source: BPM Geosynthetics, GRI-GM13.

Smooth vs. Textured HDPE Geomembrana

- Smooth HDPE: Maximizes impermeability and cost-efficiency, ideal for flat surfaces like pond liners. Permeability is 20% lower than textured variants.

- Textured HDPE: Features embossed patterns (e.g., pyramidal, dimpled) to increase friction by 30%, suitable for slopes up to 45° (BPM Geosynthetics, 2024).

3. Major Applications of HDPE Geomembrana

HDPE geomembrana’s versatility drives its use across multiple sectors, with a 2024 market share of 65% in containment applications (Geosynthetic Institute). Below are detailed applications, supported by data and case studies.

3.1 Geomembrana in HDPE – Landfill Liners and Caps

HDPE geomembrana is the cornerstone of landfill containment, preventing leachate from contaminating groundwater.

- Role: Primary/secondary liners, landfill caps.

- Performance: 2.0 mm HDPE liners reduce leachate seepage by 99.9% (ASTM D5887).

- Case Study: A 100,000 m² landfill in Saudi Arabia used 2.0 mm HDPE geomembrana, achieving 95% reduction in contamination risks.

- Standards: Complies with EPA Subtitle D and EU Landfill Directive.

- Market Share: 40% of HDPE geomembrana is used in landfills, per Technavio.

3.2 Geomembrana in HDPE – Wastewater Treatment Facilities

HDPE geomembrana lines anaerobic digesters, lagoons, and sludge ponds, withstanding corrosive chemicals.

- Role: Liners for wastewater lagoons, settling ponds.

- Performance: 1.5 mm HDPE resists pH 2–12 solutions for 20+ years (ASTM D5322).

- Case Study: A 50,000 m² wastewater lagoon in Sri Lanka used 1.0 mm HDPE geomembrana, reporting zero leaks over five years.

- Market Data: 20% of HDPE geomembrana production supports wastewater treatment (Technavio, 2024).

3.3 Geomembrana in HDPE – Mining Operations

HDPE geomembrana contains acidic or cyanide-based solutions in heap leach pads and tailings storage.

- Role: Liners for heap leach pads, tailings ponds.

- Performance: 2.0 mm HDPE withstands 0.1 M sulfuric acid for 15+ years.

- Case Study: A 200,000 m² tailings facility in South Africa used 1.5 mm textured HDPE, reducing environmental impact by 90%.

- Growth: Mining applications grew by 12% in 2024, per Mordor Intelligence.

3.4 Geomembrana in HDPE – Aquaculture Ponds

HDPE geomembrana ensures water quality in fish and shrimp farms, preventing seepage and contamination.

- Role: Liners for aquaculture ponds.

- Performance: 0.6 mm HDPE reduces water loss by 98% (ASTM D5887).

- Case Study: BPM supplied 300,000 m² of 0.6 mm HDPE geomembrana for a Sri Lankan shrimp farm, boosting yield by 15%.

- Sustainability: Non-toxic, recyclable, and compliant with ISO 14001.

3.5 Water Reservoirs and Canals

HDPE geomembrana minimizes seepage in irrigation canals and potable water reservoirs, critical in water-scarce regions.

- Role: Liners for reservoirs, canals, water tanks.

- Performance: 1.5 mm HDPE saves 1.2 million gallons of water per hectare annually.

- Case Study: A 50,000 m² reservoir in India used 2.0 mm HDPE, reducing water loss by 92%.

- Market Trend: 25% of HDPE geomembrana demand comes from water management (DataIntelo, 2024).

3.6 Oil and Gas Containment

HDPE geomembrana provides secondary containment for fuel storage and refineries, preventing soil pollution.

- Role: Secondary containment systems, spill containment.

- Performance: 1.5 mm HDPE resists hydrocarbons for 20+ years (ASTM D5322).

- Case Study: A UAE oil refinery used 1.0 mm HDPE for a 10,000 m³ spill containment system, preventing groundwater contamination.

- Standards: Meets API 650 and OSHA requirements.

3.7 Civil Engineering Projects

HDPE geomembrana prevents water infiltration in tunnels, highways, and dams, extending infrastructure lifespan.

- Role: Tunnel liners, roadbed barriers, dam liners.

- Performance: 2.0 mm HDPE reduces maintenance costs by 30% (ASTM D5887).

- Case Study: A Chinese highway project used 1.5 mm HDPE, reducing water damage by 85%.

- Market Share: 15% of HDPE geomembrana is used in civil engineering (Geosynthetic Institute).

4. Benefits of Geomembrana HDPE

HDPE geomembrana outperforms alternatives like PVC or LLDPE, securing a 60% market share (Layfield Group, 2024). Key advantages include:

- Superior Chemical Resistance: Inert to acids, alkalis, and hydrocarbons, ideal for aggressive environments.

- Longevity: Service life of 50 years, reducing replacement costs by 40%.

- Impermeability: Blocks 99.9% of fluid migration (ASTM D5887).

- UV Stability: Retains 90% strength after 1600 hours of UV exposure.

- Cost-Effective: 20–30% cheaper than concrete or clay liners, with 50% faster installation.

- Eco-Friendly: Non-toxic, recyclable, and ISO 14001-compliant.

- Ease of Installation: Thermal welding ensures leak-free seams, cutting labor costs by 25%.

5. Installation Process for Geomembrana in HDPE

Proper installation maximizes HDPE geomembrana performance. BPM Geosynthetics recommends the following steps:

- Subgrade Preparation: Remove sharp objects, compact subgrade to 95% Proctor density.

- Panel Deployment: Unroll panels perpendicular to slopes, allowing 10–15 cm wrinkles for thermal expansion.

- Welding: Use dual-hot wedge welding (300–400°C, 1.5–2.5 m/min) for flat areas or extrusion welding for patches.

- Seam Testing: Conduct peel tests (ASTM D6392), shear tests, and electronic leak location surveys (ELLS) for 100% seam integrity.

- Anchoring: Secure edges in trenches or with mechanical bars to prevent wind uplift.

- Covering: Apply geotextiles or soil to protect from UV and mechanical damage.

Case Study: A 2024 Chilean landfill project installed 75,000 m² of 1.5 mm HDPE geomembrana, achieving zero leaks after ELLS testing.

6. Challenges and Solutions

While HDPE geomembrana is highly effective, challenges may arise:

- Puncture Risk: Sharp subgrade objects can damage liners. Solution: Use geotextile underlays to increase puncture resistance by 20%.

- Thermal Expansion: HDPE expands in heat, causing wrinkles. Solution: Allow 10–15 cm slack during installation.

- Seam Failures: Poor welding can lead to leaks. Solution: Employ certified welders and conduct 100% seam testing.

- UV Degradation: Prolonged exposure weakens liners. Solution: Cover with soil or geotextiles within 30 days.

7. Comparison with Other Geomembranes

| Material | Chemical Resistance | Flexibility | UV Stability | Cost ($/m²) | Applications |

| HDPE | Excellent | Low | Excellent | 1.5–3.0 | Landfills, Mining, Ponds |

| PVC | Moderate | High | Moderate | 1.0–2.5 | Canals, Decorative Ponds |

| LLDPE | Good | High | Good | 1.2–2.8 | Aquaculture, Flexible Liners |

| EPDM | Good | Very High | Excellent | 2.0–4.0 | Roofing, Landscaping |

HDPE geomembrana excels in chemical resistance and durability, making it the top choice for high-risk applications.

8. How to Choose the Right Geomembrana in HDPE

Selecting the optimal HDPE geomembrana requires careful consideration:

- Thickness: Use 0.5–1.0 mm for low-risk projects (e.g., aquaculture); 1.0 mm–2.0 mm for landfills and mining.

- Surface Type: Textured for slopes >10°; smooth for flat surfaces.

- Chemical Exposure: Verify resistance to specific chemicals (e.g., sulfuric acid for mining).

- Certifications: Ensure ASTM, GRI-GM13, or ISO compliance.

- Budget: Balance thickness and texture with costs; 1.0 mm HDPE averages $1.5–2.0/m².

Pro Tip: Request samples and conduct third-party testing (e.g., ASTM D5322) to confirm performance.

9. Final Thoughts

HDPE geomembrana is a pivotal solution for modern containment, offering unmatched impermeability, chemical resistance, and durability across landfills, mining, aquaculture, and water management. With a market poised to reach USD 3.2 billion by 2030, its applications are expanding, fueled by sustainable practices and smart technologies. BPM Geosynthetics’ high-quality liners, compliant with ASTM and GRI-GM13, have served 36+ countries, including 300,000 m² projects like Sri Lanka’s aquaculture farms. By choosing the right thickness, texture, and supplier, and adopting trends like sensor integration, project managers can achieve 99.9% containment efficiency while optimizing costs.

Contact BPM Geosynthetics(BPM Geomembrane)to source premium HDPE geomembrana for your next project.