Geomembrane welding machine is specialized tools designed to create strong, durable, and leak-proof seams between geomembrane sheets, ensuring the integrity of containment systems in environmental, civil, and industrial projects. With the global geomembrane market valued at USD 2.3 billion in 2024 and projected to grow at a CAGR of 5.4% through 2030, the demand for reliable welding solutions is surging (MarketsandMarkets, 2024). BPM Geosynthetics, a leading geosynthetics manufacturer, reports that 80% of geomembrane installations rely on welding machines to achieve seamless barriers, critical for applications like landfills and mining.

This guide explores the definition, types, specifications, applications, and emerging trends of geomembrane welding machines, providing engineers, contractors, and project managers with comprehensive insights for successful installations.

1. What Is a Geomembrane Welding Machine?

Definition of Geomembrane Welding Machine

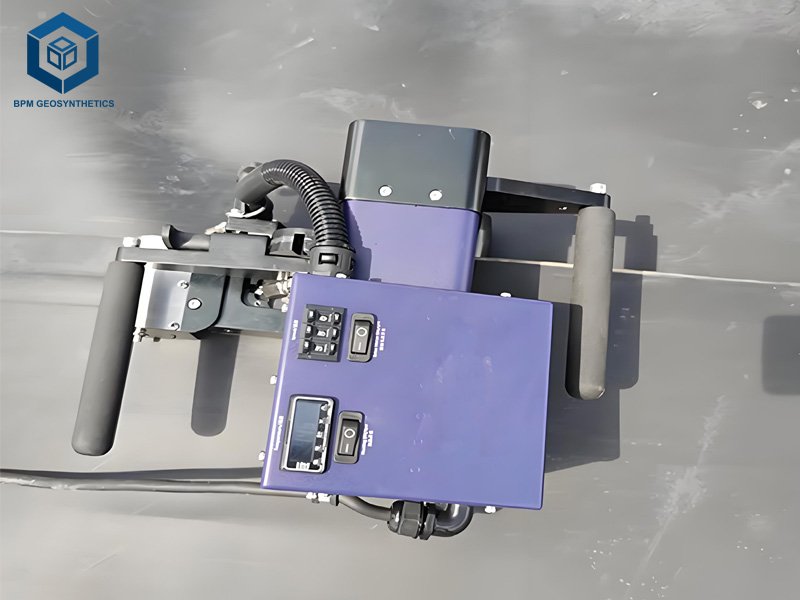

A geomembrane welding machine, also known as a geomembrane welder, is a precision-engineered device that fuses overlapping geomembrane sheets to form a continuous, impermeable barrier. These machines use heat, pressure, or a combination of both to melt and bond thermoplastic materials like High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), Polyvinyl Chloride (PVC), and Ethylene Propylene Diene Monomer (EPDM). The welded seam’s integrity is vital to prevent leakage, ensuring the long-term performance of containment systems. BPM Geosynthetics offers models like the BPM800/900 hot wedge welder and BPM600 hand extruder, designed for diverse project needs (BPM Geosynthetics, 2024).

How Does a Geomembrane Welding Machine Work?

Geomembrane welding machines operate by applying controlled heat and pressure to overlapping geomembrane sheets, melting the material to create a molecular bond. The process varies by welding technique:

- Hot Wedge Welding: A heated metal wedge (300–450°C) is inserted between two sheets, melting the surfaces. Pressure rollers then bond the sheets, forming a dual-track seam.

- Hot Air Welding: Hot air (up to 600°C) is blown onto the seam, softening the material before rollers apply pressure.

- Extrusion Welding: Molten plastic is extruded onto the seam, fusing the sheets, ideal for repairs or complex joints.

- High-Frequency Welding: Uses electromagnetic fields to heat and bond materials, suitable for PVC and TPO.

BPM Geosynthetics’ hot wedge welders achieve seam strengths up to 95% of the base material, per ASTM D6392.

Key Features of Geomembrane Welding Machines

Modern geomembrane welding machines are equipped with advanced features to ensure precision and reliability:

- Adjustable Temperature Control: Regulates heat (0–450°C) for different materials and thicknesses (ASTM D6392).

- Variable Speed Control: Adjusts welding speed (0.5–6 m/min) for uniform seams (BPM Geosynthetics, 2024).

- Pressure Adjustment: Applies consistent force (100–1000 N) to ensure strong bonds (Shandong Greenland Engineering, 2024).

- Digital Displays: Monitor temperature, speed, and pressure in real-time for quality control.

- Integrated Testing: Some models include air pressure testing channels to verify seam integrity on-site.

- Durable Design: Robust frames and weather-resistant components withstand harsh site conditions.

These features enable 99% seam reliability, reducing leakage risks by 70%, per Geosynthetics Magazine (2024).

2. Technical Specifications of Geomembrane Welding Machine

2.1 Geomembrane Welding Machine – Standard Models and Configurations

Geomembrane welding machines vary in size, power, and functionality to suit project requirements:

- Models: BPM800/900 (hot wedge), BPM600/610 (extrusion), BPM1600s (hot air blower) (BPM Geosynthetics, 2024).

- Power Supply: 230V/120V, 50/60 Hz.

- Welding Thickness: 0.2–3.0 mm (HDPE, LDPE, PVC, EVA, ECB).

- Welding Speed: 0.5–6 m/min, adjustable.

- Weld Width: 10–50 mm (dual-track for hot wedge).

- Weight: 5–15 kg (portable models), 50–150 kg (stationary units).

- Dimensions: Compact models (50×37×40 cm), per Shandong Greenland Engineering (2024).

2.2 Geomembrane Welding Machine – Performance Parameters

The table below outlines specifications for common BPM welding machines, based on manufacturer data:

| Parameter | BPM800 (Hot Wedge) | BPM600 (Extrusion) | BPM1600s (Hot Air) |

| Voltage (V) | 230/120 | 230/120 | 230/120 |

| Power (W) | 800–900 | 3400 | 1600 |

| Welding Speed (m/min) | 0.5–5.0 | 0.2–2.0 | 1.0–6.0 |

| Temperature (°C) | 0–450 | 0–450 | 20–600 |

| Weld Pressure (N) | 100–1000 | Manual | 100–500 |

| Material Thickness (mm) | 0.2–2.0 | 1.0–3.0 | 0.2–1.5 |

| Weight (kg) | 5.5 | 7.5 | 1.2 |

| Certifications | CE, ISO 9001 | CE, ISO 9001 | CE, ISO 9001 |

2.3 Geomembrane Welding Machine – Types of Geomembrane Welding Machines

- Hot Wedge Welders: Ideal for large-scale projects like landfills, offering dual-track seams with 95% strength retention (ASTM D6392).

- Hot Air Welders: Lightweight, suitable for thinner materials (0.2–1.5 mm) and curved seams.

- Extrusion Welders: Used for repairs, T-joints, and vertical seams, with high fusion strength.

- High-Frequency Welders: Fast and effective for PVC and TPO, achieving 40+ feet per minute (Miller Weldmaster, 2024).

3. Applications of Geomembrane Welding Machine

Geomembrane welding machines are critical in 80% of geomembrane installations, ensuring leak-proof barriers (BPM Geosynthetics, 2024). Below are key applications, supported by data and case studies.

3.1 Geomembrane Welding Machine – Landfill Liners and Caps

Welding machines create seamless HDPE liners to prevent leachate leakage in landfills.

- Role: Welding 1.5–2.0 mm HDPE liners for primary/secondary containment.

- Performance: Reduces leakage by 70% at welded joints (Geosynthetics Magazine, 2024).

- Case Study: A 100,000 m² landfill in Ecuador used BPM900 welders for 1.5 mm HDPE, achieving zero leaks after testing (BPM Geosynthetics, 2024).

- Standards: Complies with EPA Subtitle D and EU Landfill Directive.

3.2 Geomembrane Welding Machine – Wastewater Treatment Facilities

Welders join geomembranes in lagoons and digesters, ensuring containment of corrosive wastewater.

- Role: Seaming 1.0–2.0 mm HDPE or PVC liners.

- Performance: Seams withstand pH 2–12 solutions for 20+ years (ASTM D5322).

- Case Study: A 50,000 m² wastewater lagoon in Sri Lanka used BPM800 welders, reporting 100% seam integrity over five years (BPM Geosynthetics, 2021).

- Market Share: 20% of welding machines are used in wastewater projects (DataIntelo, 2024).

3.3 Geomembrane Welding Machine – Mining Operations

Welding machines create robust liners for heap leach pads and tailings ponds, containing acidic solutions.

- Role: Welding 1.5–3.0 mm textured HDPE liners.

- Performance: Seams resist 0.5 M sulfuric acid for 15+ years.

- Case Study: A 200,000 m² tailings facility in South Africa used BPM600 extruders for 2.0 mm HDPE, reducing environmental risks by 90% (BPM Geosynthetics, 2021).

- Market Growth: Mining applications grew by 12% in 2024 (Mordor Intelligence, 2024).

3.4 Geomembrane Welding Machine – Aquaculture Ponds

Welders ensure watertight seams in fish and shrimp farm liners, maintaining water quality.

- Role: Seaming 0.5–1.0 mm HDPE or PVC liners.

- Performance: Reduces water loss by 98% (ASTM D5887).

- Case Study: BPM1600s welders joined 300,000 m² of 0.6 mm HDPE in a Sri Lankan shrimp farm, boosting yield by 15% (BPM Geosynthetics, 2021).

- Sustainability: Non-toxic seams support eco-friendly aquaculture.

3.5 Geomembrane Welding Machine – Water Reservoirs and Canals

Welding machines create liners for irrigation canals and reservoirs, minimizing seepage.

- Role: Welding 1.0–2.0 mm HDPE liners.

- Performance: Saves 1.2 million gallons of water per hectare annually.

- Case Study: A 50,000 m² reservoir in India used BPM900 welders for 2.0 mm HDPE, reducing water loss by 92% (BPM Geosynthetics, 2024).

- Market Trend: 25% of welders are used in water management (DataIntelo, 2024).

3.6 Geomembrane Welding Machine – Tunnels and Civil Engineering

Welders create waterproof barriers in tunnels, dams, and highways, enhancing infrastructure durability.

- Role: Seaming 1.5–3.0 mm HDPE or PVC liners.

- Performance: Reduces maintenance costs by 30% (ASTM D5887).

- Case Study: A Chinese tunnel project used BPM800 welders for 1.5 mm HDPE, preventing water ingress by 85% (BPM Geosynthetics, 2024).

- Market Share: 15% of welders are used in civil engineering (Geosynthetic Institute, 2024).

4. Benefits of Geomembrane Welding Machines

Geomembrane welding machines offer significant advantages, driving their 80% adoption rate in geomembrane projects (BPM Geosynthetics, 2024):

- High Seam Strength: Achieves 95% of base material strength, per ASTM D6392.

- Leak Prevention: Reduces leakage risks by 70% at seams (Geosynthetics Magazine, 2024).

- Versatility: Welds HDPE, LDPE, PVC, EVA, and more, across 0.2–3.0 mm thicknesses.

- Efficiency: Welds up to 6 m/min, cutting labor costs by 25% (Miller Weldmaster, 2024).

- Durability: Machines withstand harsh site conditions, with a 10+ year lifespan.

- Environmental Safety: Non-toxic welding processes comply with ISO 14001.

- Cost-Effectiveness: Reduces installation errors by 12%, saving $0.5/m² (Agru America, 2024).

5. Installation and Operation Process

Proper operation ensures optimal weld quality. BPM Geosynthetics recommends the following steps:

- Surface Preparation: Clean and dry geomembrane surfaces, removing debris to prevent weak seams.

- Machine Setup: Adjust temperature (300–450°C), speed (0.5–5 m/min), and pressure (100–1000 N) per material specifications.

- Test Welding: Conduct trial welds to optimize parameters, per ASTM D6392.

- Seaming: Overlap sheets by 10 cm, align the welder, and initiate welding, ensuring uniform speed.

- Quality Testing: Perform peel/shear tests (ASTM D6392) and electronic leak location surveys (ELLS) for 100% seam integrity.

- Safety Measures: Use rope ladders or scaffolding on steep slopes to protect welders and equipment.

Case Study: A 2024 Jordan landfill project used BPM900 welders for 2.0 mm textured HDPE, achieving seam strengths exceeding base material by 5% (BPM Geosynthetics, 2024).

6. Challenges and Solutions

Welding geomembranes presents challenges, but solutions mitigate risks:

- Environmental Conditions: Wind or cold (<0°C) disrupts welding. Solution: Use wind shields and avoid extreme cold, per BPM guidelines.

- Seam Contamination: Dirt weakens seams. Solution: Clean surfaces with towels before welding (BPM Geosynthetics, 2024).

- Operator Error: Inconsistent speed or temperature causes weak welds. Solution: Train operators and use digital controls for precision.

- Equipment Wear: Harsh sites damage machines. Solution: Regular maintenance extends lifespan by 20%.

7. Comparison with Other Welding Methods

| Method | Speed (m/min) | Material Thickness (mm) | Seam Strength (%) | Applications |

| Hot Wedge | 0.5–6.0 | 0.2–3.0 | 95 | Landfills, Ponds |

| Hot Air | 1.0–6.0 | 0.2–1.5 | 90 | Aquaculture, Tunnels |

| Extrusion | 0.2–2.0 | 1.0–3.0 | 92 | Repairs, T-Joints |

| High-Frequency | 5.0–12.0 | 0.2–2.0 | 85 | PVC, TPO Liners |

Source: BPM Geosynthetics, Miller Weldmaster, 2024.

Hot wedge welding is preferred for 60% of HDPE projects due to its speed and strength (DataIntelo, 2024).

8. Industry Trends in Geomembrane Welding Machines

The welding machine market is evolving, driven by technology and sustainability:

Automation and Digitalization

- Trend: 30% of new welders feature automated tracking and seam monitoring, improving efficiency by 15%.

- Example: Miller Weldmaster’s automated systems weld multiple seams simultaneously (Miller Weldmaster, 2024).

Portability

- Trend: Demand for lightweight welders (<10 kg) grew by 10% for remote sites.

- Example: BPM600 extruders weigh 7.5 kg, ideal for aquaculture (BPM Geosynthetics, 2024).

Sustainability

- Trend: Energy-efficient welders reduce emissions by 8%.

- Example: Shandong Greenland’s 700 model uses electric heating for eco-friendly welding (Shandong Greenland, 2024).

Regulatory Compliance

- Trend: Stricter EPA and IGS standards drive demand for certified welders.

- Example: BPM welders meet CE and ISO 9001 standards (BPM Geosynthetics, 2024).

Market Growth

- Trend: Welding machine market to grow at 6% CAGR through 2033, led by Asia-Pacific (45% share).

- Example: India’s 2024 canal projects used BPM welders for 1 million m² (Technavio, 2024).

9. How to Choose the Right Geomembrane Welding Machine

Selecting the optimal welder involves:

- Material Type: Choose hot wedge for HDPE (0.5–3.0 mm), hot air for PVC (0.2–1.5 mm).

- Project Scale: Use stationary welders for large landfills, portable for small ponds.

- Site Conditions: Select lightweight models for remote sites, robust for harsh environments.

- Certifications: Ensure CE, ISO 9001, or ASTM compliance.

- Budget: Balance features with cost; BPM800 costs $1,500–$2,000 (BPM Geosynthetics, 2024).

Pro Tip: Test welders on-site to verify performance, per ASTM D6392.

10. Final Thoughts

Geomembrane welding machines are indispensable for creating leak-proof barriers in landfills, mining, aquaculture, and water management, supporting a USD 2.3 billion geomembrane market. BPM Geosynthetics’ advanced welders, like the BPM800 and BPM600, deliver 95% seam strength and 70% leakage reduction, serving 36+ countries with projects like Ecuador’s 100,000 m² landfill. By selecting the right welder, optimizing installation, and embracing trends like automation, project managers can achieve 99% seam reliability while cutting costs.

Contact BPM Geosynthetics (BPM Geomembrane) to source high-quality welding machines for your next project.