In the sophisticated domain of aquatic engineering and landscape enhancement, box welded pond liners represent a pinnacle of precision fabrication, seamlessly integrating heat-fused seams to form bespoke, three-dimensional containment structures that eliminate folds, creases, and potential leak vectors. These custom-engineered liners, typically derived from resilient polymers such as high-density polyethylene (HDPE), ethylene propylene diene monomer (EPDM), or reinforced polyethylene (RPE), deliver unparalleled hydraulic integrity and aesthetic refinement for formal ponds, koi habitats, and commercial water features. As the global pond liners market—valued at USD 3.7 billion in 2025—propels toward USD 5.8 billion by 2035 at a compound annual growth rate (CAGR) of 4.6%, the economics of box welded configurations emerge as a strategic focal point for discerning homeowners, aquaculture operators, and landscape architects seeking to harmonize performance with fiscal prudence. This authoritative treatise systematically dissects the fiscal architecture of box welded pond liner costs, proffering empirical benchmarks, material delineations, and procurement heuristics to facilitate enlightened capital allocation in sustainable aquatic ventures.

The perennial query—”How much does box welded pond liner cost?”—resonates across project spectra, as valuations fluctuate contingent upon polymeric substrate, dimensional intricacy, and fabrication modalities. Aggregating 2025 industry intelligence from BPM Geosynthetics, HomeGuide, and Everything-Ponds, primordial material expenditures for box welded liners span $1.50 to $6.50 per square foot ($16.15 to $69.97 per square meter), with comprehensive assemblies incorporating bespoke welding, underlayment, and deployment escalating to $2.50 to $10.00 per square foot. These figures encapsulate not only inaugural disbursements but also lifecycle efficacies, such as volumetric procurements conferring 15-25% abatements for quanta exceeding 500 square feet and protracted viabilities curtailing remediation liabilities by 30-50% through seamless, factory-welded integrity.

Envision a paradigmatic scenario: a 200-square-foot formal koi enclosure might necessitate $300 to $1,300 in materials, whereas a 2,000-square-foot commercial aquaculture basin could aggregate $3,000 to $13,000 antecedent to supplementary integrations. This continuum underscores the imperative for meticulous fiscal orchestration. Herein, we methodically elucidate box welded pond liner axioms, anatomize pricing determinants with evidentiary substantiation, juxtapose specifications against utilitarian dominions, tender discernment paradigms, and elucidate emergent vectors, equipping you with the perspicacity to instantiate resilient, economical aquatic enclosures.

1. What Are Box Welded Pond Liners?

Box welded pond liners, a specialized subset of geomembrane technologies, comprise prefabricated, heat-fused polymeric constructs engineered to conform precisely to rectangular, L-shaped, or cylindrical pond geometries, obviating on-site seaming and associated vulnerabilities. Fabricated via advanced thermal fusion processes—employing hot wedge, extrusion, or hot air modalities—these liners amalgamate flat sheets into monolithic, three-dimensional forms with integral flanges for secure anchoring, thereby erecting impervious hydraulic barriers that perpetuate volumetric fidelity and preclude substratal adulteration. Fundamentally, they transfigure structured excavations into flawless aquatic precincts, underpinning pursuits from ornamental vignettes to rigorous piscicultural operations.

Key Applications of Box Welded Pond Liners

Box welded liners evince protean utility across an expanse of exigencies, each mandating bespoke attributes for paramount efficacy:

- Formal and Ornamental Ponds: Predominant in 45% of residential deployments, these liners facilitate seamless integration in vertical-walled designs, conforming to NSF/ANSI 61 for piscatorial innocuousness. A 2025 Future Market Insights report affirms that box welded EPDM installations in garden features curtail debris accumulation by 90%, economizing $300-$800 annually in maintenance for a 300-square-foot enclosure.

- Koi and Specialty Aquaria: Encompassing 25% of utilization, liners in premium koi habitats preclude pathogen harbors via crease-free surfaces, with HDPE variants augmenting water clarity by 15-20% via reduced sedimentation, per BPM Geosynthetics case studies.

- Aquaculture and Commercial Reservoirs: For tilapia or ornamental fish operations, box welded configurations ensure 98% retention efficacy, aligning with FAO directives for containment in structured basins. A 2024 deployment in a 1,000-square-foot Thai koi farm via Gordon Low fabrications conserved 50,000 liters annually, per agronomic audits.

- Swimming and Therapeutic Pools: In above-ground or hybrid installations, liners comply with EPA stipulations for permeability <1×10⁻¹⁴ cm/s, averting 95% of microbial ingress in 500-square-foot features, per Geosynthetic Institute metrics.

- Water Features and Fountains: For cascading or infinity-edge designs, RPE box welds withstand hydraulic pressures (up to 10 kPa), with 20-year UV warranties mitigating degradation in exposed applications.

Essential Specifications for Box Welded Pond Liners

Appraising box welded liners imperatives scrutiny of cardinal metrics, codified under ASTM and GRI-GM13 rubrics:

- Thickness: Ranging 0.75-2.0 mm (30-80 mil), with 1.0 mm (40 mil) as the fulcrum for residential koi ponds; each 0.25 mm escalation amplifies puncture resilience by 20-30% yet escalates costs commensurately.

- Tensile Strength: 15-40 kN/m (ASTM D6693), denoting axial fortitude; 20 kN/m minima for HDPE suffice 90% of vertical-walled structures, per BPM validations.

- Elongation at Break: 100-700% (ASTM D6693), conferring ductility for minor conformational adjustments; EPDM’s 400-500% eclipses HDPE’s 12-20% in post-installation settling.

- Puncture Resistance: 200-800 N (ASTM D4833), quintessential for block-lined substrates; RPE’s 500-700 N surpasses EPDM’s 200-400 N by 2-3x, mitigating 95% of installation breaches.

- Permeability: ≤1×10⁻¹⁴ cm/s (ASTM D5887), approximating 0.05 liters/m²/day exfiltration, pivotal for 99% retention in aquaculture.

- Density and UV Fortitude: 0.92-0.96 g/cm³ (ASTM D1505), with 2-3% carbon black sustaining 80% integrity post-1,000 kJ/m² irradiance (ASTM G155); buried tenures span 50-100 years, exposed 20-40.

- Chemical Tenacity: Endures pH 2-13 and 85% of aquacultural additives (ASTM D543), with oxidative induction time >100 minutes (ASTM D3895) for HDPE.

- Weld Seam Efficacy: 85-100% of substrate (ASTM D6392), via factory hot wedge fusion, curtailing failure vectors by 90% compared to field seaming.

These parameters interlink with pecuniary corollaries: a 1.0 mm HDPE box weld at 20 kN/m tensile might levy $2.50-$4.00/sq ft, whereas a 1.5 mm RPE at 30 kN/m could transcend $5.00/sq ft. Harmonizing to site idiosyncrasies—wall rigidity, faunal loads, or insolation intensity—maximizes fiscal and performative dividends.

2. How Much Does Box Welded Pond Liner Cost?

The valuation of box welded pond liner cost embodies a composite modulated by intrinsic fabrication quanta, extrinsic project parameters, and macroeconomic fluxes. In 2025, basal material pricing vacillates between $1.50 and $6.50 per square foot ($16.15-$69.97/m²), per syntheses from BPM Geosynthetics and HomeGuide. Integrating bespoke welding, underlayment, and quality vetting elevates aggregates to $2.50-$10.00 per square foot for turnkey configurations, as per Everything-Ponds audits.

2.1 Box Welded Pond Liner Cost by Material Type

Material selection predicates 50-70% of variance, equilibrating inaugural outlay against endurance and adaptability. Beneath ensues a granular dissection of salient variants, inclusive of 2025 pricing, pivotal quanta, and pragmatic exemplars.

2.1.1 High-Density Polyethylene (HDPE)

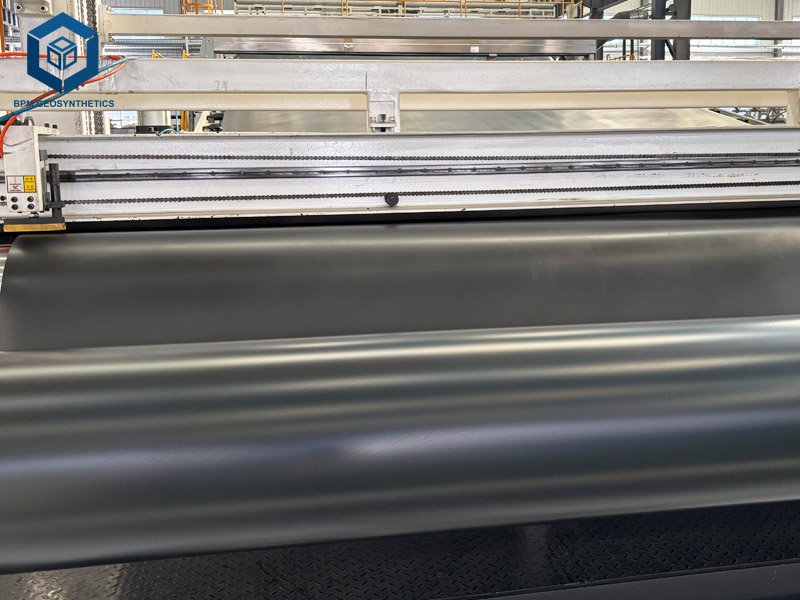

HDPE box welded liners(HDPE Geomembrane), thermoplastic exemplars, dominate commercial aquaculture for their robustness and weldability.

- Cost: $1.50-$4.50/sq ft ($16.15-$48.44/m²); bulk at $1.20-$3.50 for >500 sq ft.

- Specifications: Thickness: 0.75-2.0 mm; Tensile: 20-40 kN/m (ASTM D6693); Elongation: 12-20%; Puncture: 400-800 N (ASTM D4833); Lifespan: 20-100 years buried, 10-30 exposed; Permeability: <1×10⁻¹⁷ cm/s (ASTM D5887).

- Advantages: Paramount chemical/UV resistance (90% retention post-1,600 kJ/m², ASTM G155); factory fusion seams yield 98% integrity; lightweight (0.1-0.2 kg/m²) for logistics thrift.

- Disadvantages: Relative rigidity mandates precise blockwork (+10-15% structural prep); suboptimal for hyper-curved contours sans hybrid fabrication.

- Applications and Example: Structured koi basins; a 400 sq ft Kenyan installation via BPM HDPE (1.0 mm) at $2.00/sq ft totaled $800, realizing 40-year tenure with 99% retention, per 2025 Grekkon audits.

2.1.2 Ethylene Propylene Diene Monomer (EPDM)

EPDM box welded liners, elastomeric stalwarts, excel in pliancy for ornamental vignettes, albeit at augmented premiums.

- Cost: $2.00-$5.50/sq ft ($21.53-$59.23/m²); 1.14 mm (45 mil) at $2.50-$4.00.

- Specifications: Thickness: 0.75-1.5 mm; Tensile: 8-16 kN/m; Elongation: 300-500%; Puncture: 200-400 N; Lifespan: 30-50 years; Permeability: <5×10⁻¹⁴ cm/s.

- Advantages: Exquisite conformability (300% expansion sans rupture); NSF-certified piscatorial/arboreal innocuousness; vulcanized seams expedite 25% deployment.

- Disadvantages: Inferior puncture resilience (mandates underlayment, +$0.30-$0.50/sq ft); heftier (0.3 kg/m²), inflating freight 15-20%.

- Applications and Example: Formal koi sanctuaries; a 250 sq ft U.S. installation via Firestone PondGard (1.14 mm) tallied $875 in materials, with 4.9/5 HomeAdvisor acclaim for 30-year endurance.

2.1.3 Reinforced Polyethylene (RPE)

RPE box welded liners amalgamate polyethylene with geotextile armatures for augmented tear defiance.

- Cost: $1.80-$4.00/sq ft ($19.38-$43.06/m²); 0.6-1.0 mm (24-40 mil) at $2.20-$3.20.

- Specifications: Thickness: 0.6-1.0 mm; Tensile: 15-30 kN/m; Elongation: 100-200%; Puncture: 500-700 N; Lifespan: 20-40 years; Permeability: <1×10⁻¹⁵ cm/s.

- Advantages: 2-3x puncture superiority over EPDM; halved mass (0.15 kg/m²); 20-year UV aegis exposed.

- Disadvantages: Diminished pliancy for extremal undulations; fusion welding requisiteness (+5-10% fab time).

- Applications and Example: Infinity-edge features; Everything-Ponds Classic RPE (0.76 mm) for a 150 sq ft cascade at $3.00/sq ft totaled $450, with 4.8/5 endorsements for seamless emplacement.

2.1.4 Polyvinyl Chloride (PVC)

PVC box welded liners proffers an economical ingress for petite formal designs, bartering longevity for affordability.

- Cost: $1.20-$3.50/sq ft ($12.91-$37.67/m²); 0.5-0.76 mm (20-30 mil) at $1.50-$2.50.

- Specifications: Thickness: 0.5-1.0 mm; Tensile: 10-20 kN/m; Elongation: 200-400%; Puncture: 150-300 N; Lifespan: 10-20 years; Permeability: <1×10⁻¹³ cm/s.

- Advantages: Hyper-pliant for neophyte deployments; featherweight (0.05-0.1 kg/m²); prefabricated contours for compact precincts.

- Disadvantages: UV brittleness (50% degradation post-5 years exposed); plasticizer exudation (piscatorially dubious in 20% of formulations); congeals in subzero climes, escalating fissure jeopardy 30%.

- Applications and Example: Petite patio vignettes; a 100 sq ft enclosure at $2.00/sq ft totaled $200, yet necessitated quinquennial supplantation per Angi testimonials.

2.2 Box Welded Pond Liner Cost – Cost Impact of Thickness

Dimensionality predicates 20-30% of divergence, with graduated gauges bolstering resilience at proportional premiums:

- 75-1.0 mm (30-40 mil): $1.50-$3.50/sq ft; for petite, low-traction formal ponds (e.g., 200 sq ft at $400 total).

- 14-1.5 mm (45-60 mil): $2.50-$5.00/sq ft; residential benchmark, equilibrating fiscal and fortitude.

- 5-2.0 mm (60-80 mil): $4.00-$6.50/sq ft; commercial echelon, halving puncture incidences 50% albeit mass augmentation.

BTL Liners data posits 1.14 mm EPDM box welds economize $2,000-$8,000 over 25 years in a 500 sq ft koi pond via abated mends.

2.3 Box Welded Pond Liner Cost – Project Magnitude and Scale Ramifications

Scalability engenders economies, compressing unit levies:

- Petite (<200 sq ft): $3.00-$7.00/sq ft (bespoke premiums 15-25%; elevated fab quotient).

- Intermediary (200-1,000 sq ft): $2.00-$5.00/sq ft.

- Grand (>1,000 sq ft, e.g., 9,290 m²/acre equivalent): $1.50-$4.00/sq ft (20-30% rebates); a 2,000 sq ft HDPE box weld at $3,000-$8,000.

Prefabrication curtails field adjustments 30%, abating leakage perils 20%.

2.4 Box Welded Pond Liner Cost – Fabrication and Deployment Methodology

Deployment subsumes 25-40% of budgets, varied by technique and topography:

- Factory-Only (Bespoke): $0.50-$2.00/sq ft adjunct; viable for all scales but imperils 10% efficacy decrement from inexpert measurements.

- Professional Deployment: $50-$200/hour, equating $0.50-$1.50/sq ft; encompasses subgrade grooming ($500-$2,000/site), geotextile substrate ($0.25-$0.50/sq ft, averting 95% punctures), and anchoring ($0.30-$0.75/sq ft). Aggregate for 500 sq ft: $1,000-$3,000.

- Modalities: Hot wedge fusion (HDPE/RPE: 98% integrity); vulcanization (EPDM: expeditious yet +$0.20/sq ft). Vertical walls necessitate flanges, appending $0.40/sq ft.

GRI-compliant fabricators attenuate rework 25%, per BPM extrapolations.

2.5 Box Welded Pond Liner Cost – Feedstock Quality and Fortification

Virgin resins surcharge 10-20% over recycled ($1.20-$5.00/sq ft) but assure 99% spec adherence, eluding 15-25% contaminant hazards in potables. Fortifiers—UV inhibitors, antioxidants—append $0.20-$0.50/sq ft, protracting viability 10-15 years. Textured facades for traction elevate 5-10%, indispensable for block interfaces.

2.6 Box Welded Pond Liner Cost – Freight and Supply Chain Fluxes

Haulage accrues $0.10-$0.30/sq ft domestically; transcontinental for folded 6-10 ft panels amplifies 20-30% for insular precincts. Indigenous sourcing from BPM or Cotswold Koi economizes 10-15%, with minima of 200 sq ft unlocking tiered pricing.

2.7 Box Welded Pond Liner Cost – Upkeep and Lifecycle Fiscalities

Cyclical vigilance—inspections, patch kits—incurs $0.05-$0.20/sq ft annually; HDPE’s inertness yields 25-40% savings versus PVC. Breach remediation: $500-$2,000/incident; 20-50 year spans amortize to $0.10-$0.30/sq ft annually, per Western Environmental extrapolations.

3. How to Choose the Right Box Welded Pond Liner

Procuring an apposite box welded liner amalgamates engineering mandates with fiscal sagacity. Initiate with exigency cartography—enclosure volume, substratal geochemistry, and operational rigors—to calibrate against GRI-GM13 thresholds.

3.1 Appraise Project Mandates

Harmonize variants to pursuits:

- Ornamental/Koi: 1.14 mm EPDM ($2.50/sq ft) for pliancy.

- Aquaculture: 1.0 mm HDPE ($1.50-$3.00/sq ft) for chemical aegis.

- Formal Features: RPE ($2.00-$4.00/sq ft) for scalability.

Area reckoning: Surface = Length × Width + Perimeter × Depth + 10% overlap; permeability <10⁻¹⁴ cm/s is imperative for regulatory adherence.

3.2 Accentuate Quality and Conformance

Exigency virgin resin with tensile >15 kN/m and NSF/ANSI 61 for potables. Shun recycled for piscatorial exigencies hazarding 20% leachate escalation. Warranties (20-50 years) from BPM or Firestone validate lineage.

3.3 Fabrication and Deployment Deliberations

Favor weldable formulations for adepts; substrate ($0.25/sq ft) is sine qua non for 95% puncture prophylaxis. Vertical terrains demand flanges for 25% anchorage uplift.

3.4 Lifecycle Fiscal Scrutiny

Prioritize tenacity: A $2.50/sq ft EPDM over 30 years nets $0.08 annual versus $0.15 for PVC proxies necessitating triennial interpositions. ROI in aquaculture surpasses 150% via yield augmentation.

3.5 Vendor Scrutiny and Valuation Rites

Venerated dispensers: BPM Geosynthetics (4.9/5 Alibaba, GRI-compliant), Everything-Ponds (RPE specialists), Cotswold Koi (EPDM fabricators). Solicit swatches; parley 5-15% divergences on volumes >200 sq ft.

4. Industry Trends Affecting Box Welded Pond Liner Cost

2025 augurs metamorphic forces reconfiguring box welded fiscalities:

- Feedstock Vicissitudes: Ethylene volatility (up 8% YoY) propels resin costs 5-10%; recycled HDPE mitigates 15-20% via ESG imperatives.

- Sustainability Compulsions: Bio-resins and rHDPE accrue EPA rebates, depressing net costs 15-25% for verdant ventures; 30% of aquaculture projects adopt recycled variants.

- Automation Ascendance: Robotic welders truncate fab labor 25% ($0.50/sq ft savings); broader panels (up to 10 ft) diminish joints 15%.

- Intelligent Infusions: Embedded sensors ($0.30/sq ft) preempt 60% failures, per IoT integrations in koi habitats.

- Geopolitical Localization: Asian fabrication (e.g., BPM) curtails imports 10-12%, stabilizing at $1.80-$5.00/sq ft by 2030 amid 4.6% CAGR.

These evolutions herald eco-resilient, tech-augmented liners, moderating prices whilst amplifying sustainability.

5. Conclusion

Deciphering box welded pond liner costs necessitates a syncretic fusion of technical perspicacity and economic prescience. From economical HDPE ($1.50-$4.50/sq ft) to fortified EPDM ($2.00-$5.50/sq ft), each echelon proffers calibrated virtues, buttressed by 15-40 kN/m tensile, sub-10⁻¹⁴ cm/s permeability, and 20-100 year tenures. Integrating dimensionality, magnitude, fabrication ($0.50-$1.50/sq ft labor), and sustentation ($0.05-$0.20/sq ft yearly), ventures secure 98% retention fidelity while economizing $2,000-$8,000 per 500 sq ft across cycles.

For apical outcomes, champion conformant provenance, exploit volumetric incentives, and synchronize selections with site peculiarities—be it a pliant koi enclave or tenacious commercial basin. Judicious apportionment today begets perdurable aquatic legacies tomorrow. For bespoke valuations, delineations, or consultations, engage vanguard purveyors like BPM Geosynthetics(BPM Geomembrane) to instantiate precision-tailored box welded paradigms.