Geomembran HDPE, also known as HDPE Geomembrane, is he preferred product for lining projects. It is designed to protect structures from the ingress of moisture, water, liquids, radon, carbon dioxide and methane together with chemicals.

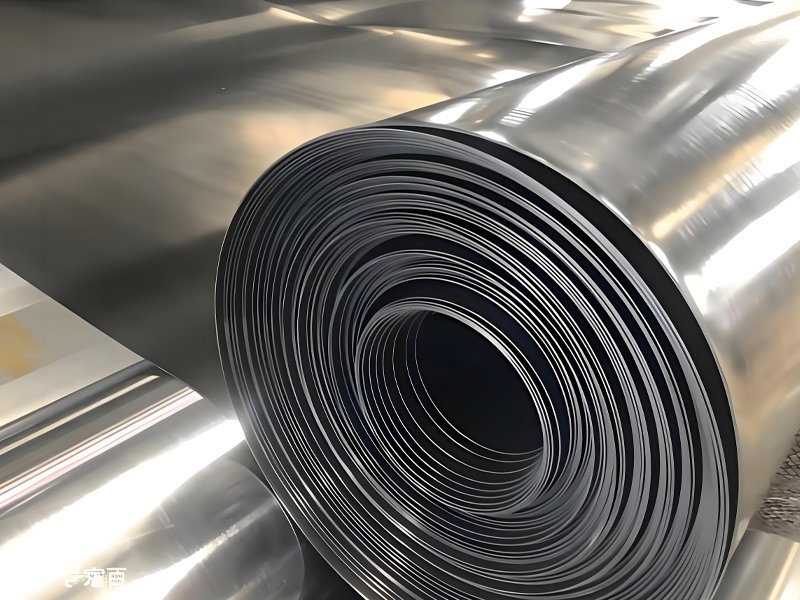

As the geomembane liner manfuacturer and supplier, BPM Geosynthtetics offers high quality HDPE geomembrane liner with thickness of 0.2 mm – 3.0 mm or 20 – 120 mil. OEM/ODM are available.

1. What Is Geomembran HDPE?

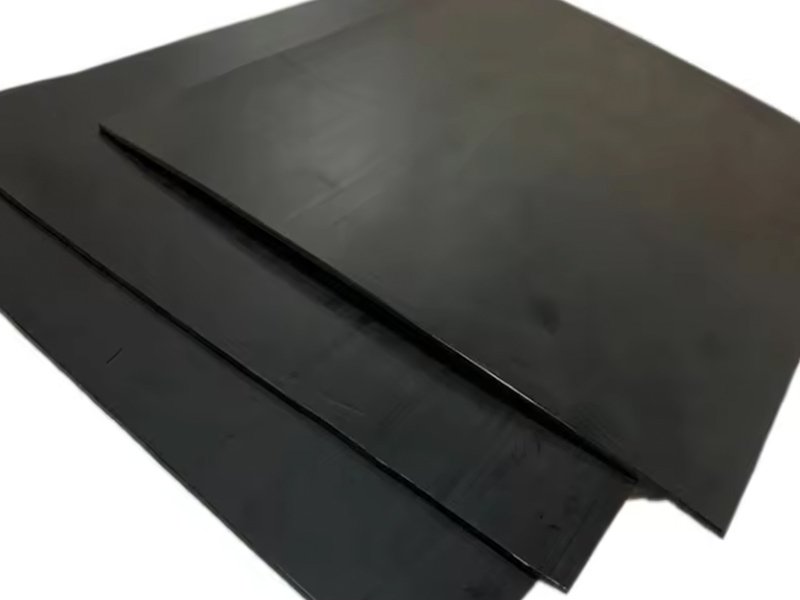

Geomembran HDPE (High-Density Polyethylene) is a type of geomembrane that is manufactured through extrusion in a flat die and calender. It is composed of high-density polyethylene premium (97.5%), carbon black (2.5%), and antioxidants. This composition provides excellent weather resistance and a high level of stress cracking resistance.

Geomembran HDPE is primarily used as a waterproof barrier in various hydraulic works and environmental projects. In hydraulic applications, it serves as a reliable barrier for water reservoirs used in agriculture, canals, treatment plants, settling ponds, evaporation ponds, farms, golf courses, and more. It effectively prevents water seepage and ensures proper containment.

In environmental projects, HDPE geomembrans act as barriers to contain liquid or solid contaminants. They are commonly used in waste landfills, leachate containment, slurry containment, mining waste containment, and protection against leaks in industries such as petrochemical, airports, harbors, and more. The geomembrane HDPE liner prevents the migration of contaminants, thus safeguarding the surrounding environment.

BPM offers different types of geomembran HDPE liner products, including smooth geomembrane, textured geomembrane, and composite geomembrane. These liners are made from high-quality polyethylene primary resin, with the addition of carbon black, anti-aging agents, anti-ultraviolet absorbents, and stabilizers. The production process involves three-layer co-extrusion blow molding or calendaring technology, ensuring the geomembranes’ durability and effectiveness.

The geomembran HDPE liner plays a important role in preventing landfill leachate from contaminating the soil. It acts as a barrier between the waste and the surrounding environment. Additionally, the construction structure, combined with the anti-seepage geomembrane HDPE liner, allows for the proper discharge of landfill leachate through flood pipes, contributing to effective waste management.

Geomembran HDPE liners offer a reliable and efficient solution for waterproofing and containment in hydraulic and environmental applications, providing long-lasting protection for various projects.

2. What Are Advantages of Geomembran HDPE Liner for Landfill Project?

Geomembran HDPE liners have many advantages including chemical stability, anti-aging properties, high mechanical strength, cost-effectiveness, environmental friendliness, and ease of welding, make them highly suitable for landfill projects. They provide a reliable and efficient solution for preventing the migration of contaminants and protecting the environment.

2.1 Chemical Stability

Geomembrane HDPE liners exhibit excellent chemical stability, making them resistant to a wide range of substances such as high and low temperatures, asphalt, oil, tar, acid, alkali, and salt. This stability ensures long-term durability and effectiveness in containing landfill waste and preventing contamination.

2.2 Anti-Aging Properties

HDPE geomembrane liners have exceptional anti-aging and anti-ultraviolet capabilities. They are designed to withstand prolonged exposure to sunlight and harsh environmental conditions without significant degradation. This ensures that the liners maintain their integrity over an extended period, providing a reliable material guarantee for effective anti-seepage performance in landfill projects.

2.3 High Mechanical Strength

Geomembrane HDPE liners possess good mechanical strength, including breaking tensile strength and breaking elongation. This strength allows them to withstand the stresses and strains associated with landfill operations, including waste compaction, without experiencing significant damage or failure.

2.4 Cost-Effectiveness and Efficiency

HDPE geomembrane liners are cost-effective and efficient compared to traditional waterproofing materials. The use of new production technologies and scientific manufacturing processes allows for improved anti-seepage performance while lowering the overall production cost. This makes HDPE geomembrane liners a cost-effective solution for landfill projects.

2.5 Environmental Protection and Non-Toxicity

Geomembrane HDPE liners are made from non-toxic and environmentally friendly materials. The anti-seepage principle of HDPE liners involves a general physical change without the production of harmful substances. This makes them a safe and environmentally sound choice for landfill projects, aquaculture, and drinking water ponds.

2.6 Good Welding Effect

HDPE geomembrane liners can be easily welded using specialized welding machines. The welding process creates strong and reliable seams, with the strength of the weld often exceeding that of the base material. This facilitates efficient and effective installation, ensuring the integrity of the liner system and minimizing the risk of leakage.

3. How Thick Is The Geomembran HDPE?

Geomembrane HDPE is commonly employed in anti-seepage and waterproof projects, with thicknesses ranging from 0.5mm to 3.0mm (20mil to 120 mils). Available options include 0.75mm, 1.0mm, 1.25mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm, 3.5mm, and more. Among these, the 1.5mm thickness of geomembrane HDPE stands out as the optimal choice for landfills due to its exceptional durability, flexibility, and cost-effectiveness.

The 1.5mm geomembrane HDPE strikes a balance between strength and flexibility, enabling it to withstand the demanding conditions of landfill environments. Its robust construction ensures long-lasting performance, effectively preventing seepage and contamination. Additionally, the material’s flexibility allows for easy installation, conforming to the contours of the landfill site.

The 1.5mm thickness offers cost advantages compared to thicker geomembranes without compromising the anti-seepage effectiveness. Its affordability makes it an attractive solution for landfill projects, delivering a reliable and efficient barrier against leachate migration while optimizing overall project costs.

4. Case Study of Geomembran HDPE Liner for Landfill Project in Indonesia

BPM received an inquiry from Indonesian clients regarding their landfill project. Our sales team engaged in detailed discussions with them, providing information on the specifications and performance of our geomembrane liner products. We also sent them samples for testing. Impressed with the quality, the clients decided to visit our company in China to inspect our operations.

During their visit, the clients evaluated our production processes and ensured that our products met their requirements in terms of quality and price. After thorough consideration, we successfully reached an agreement for cooperation.

The specifications for the geomembrane HDPE liner in the landfill project in Indonesia were as follows: the project size was 58m*103m, requiring a total quantity of 13,066 square meters of geomembrane liner. The chosen thickness for the liner was 1.5mm, and each roll had dimensions of 7m*100m.

Through effective communication, product testing, and on-site inspections, BPM was able to establish a successful collaboration with the Indonesian clients, providing them with the appropriate geomembrane HDPE liner solution for their landfill project.

5. About BPM Geomembrane

As the the professional geomembrane manufacturer and supplier, BPM has been dedicated to supplying one stop geomembranes and services to worldwide customers since its foundation in 2010. All BPM geomembranes have passed the certificates of the ISO9001, ISO14001, TUV, Soncap, SASO, BV certificates and the test of SGS and Intertek etc. Our geomembrane products have been exported to over 36 countries.

BPM brand geomembrane products mainly include Smooth Geomembrane, Textured Geomembrane, Composite Geomembrane, etc. BPM is also providing professional design and installation service.

If you have any questions or inquiries, please contact us.