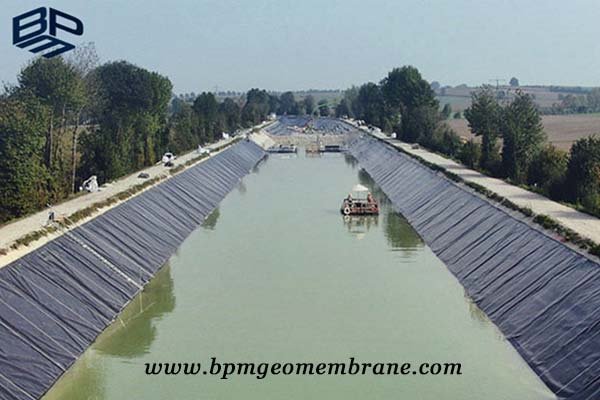

Geomembrane canal lining or canal liner is the kind of geomembrane liner which offers a cost-effective solution to mitigate water loss caused by seepage. Studies suggest that irrigation canals can lose approximately 30-40% of water due to seepage. Implementing canal liners helps to minimize this loss, ensuring a more efficient utilization of water resources in irrigation systems. BPM Geomembrane is the geomembrane liner manufacturer and suppleir, we offer total lining geomembrane canal lining solutions for irrigation systems.

1. What Is Canal Lining?

Canal lining is a technique used to reduce seepage loss of irrigation water by adding an impermeable layer to the edges of the canal trench. This impermeable layer, typically made of high-density polyethylene (HDPE) geomembrane, acts as a barrier to prevent water from seeping into the surrounding soil. Seepage can lead to significant water losses, ranging from 30 to 50 percent, making irrigation systems inefficient and contributing to water scarcity.

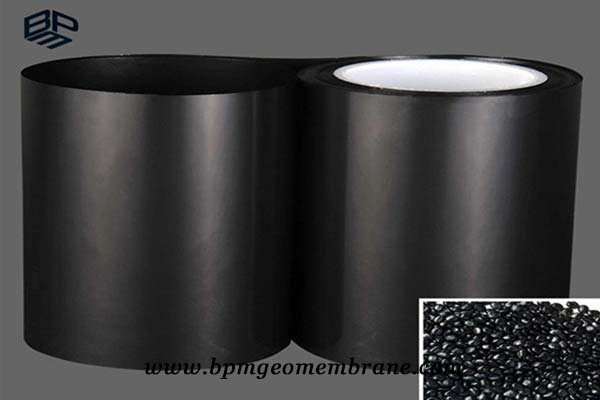

HDPE geomembrane, a milky white translucent to opaque thermoplastic resin material, is commonly used for canal lining. It possesses several desirable properties, including heat resistance, cold resistance, chemical stability, high rigidity, toughness, mechanical strength, tear resistance, and resistance to environmental stress cracking. These properties make HDPE geomembrane an ideal choice for canal lining applications.

The primary purpose of canal lining is to improve water utilization in agricultural irrigation, as more than half of freshwater usage is attributed to this sector. Inefficient canal systems with inadequate seepage prevention measures result in low water utilization coefficients. Currently, only about 20% of the total canal length incorporates anti-seepage technology.

However, the use of HDPE geomembrane for canal lining has proven to be effective in improving water utilization rates and slowing the decline of groundwater levels. Additionally, it provides a protective barrier for the soil, preventing salinization and maintaining soil quality.

By implementing canal lining techniques with HDPE geomembrane, the seepage losses can be significantly reduced, leading to more efficient irrigation systems, increased water availability, and improved sustainability in agriculture. This not only benefits farmers by conserving water resources but also contributes to overall water resource management and environmental protection.

2. What Is The Effect of Canal Lining of Irrigation Canal?

The effect of canal lining on irrigation canals can be significant. When a canal surface is lined with a geomembrane liner, it becomes smoother, resulting in reduced resistance against the flow of water. This smoothness allows water to flow with higher velocity compared to an unlined channel.

The increased velocity of flow in a lined canal enhances the channel’s capacity to carry water. It allows for a greater volume of water to be transported through the canal, improving the overall efficiency of the irrigation system.

By reducing resistance and improving flow capacity, canal lining helps to minimize water losses due to seepage. This is especially important in areas where seepage can result in significant water loss, leading to inefficiency and reduced water availability for irrigation purposes.

The increased velocity of water flow in a lined canal can also help in flushing out sediment and debris that may accumulate in the channel. This can prevent clogging and maintain the proper functioning of the irrigation system.

The effect of canal lining on irrigation canals is the promotion of improved water flow efficiency, increased water-carrying capacity, and reduced water losses due to seepage. These benefits contribute to more effective water management and utilization in agricultural practices, ultimately enhancing crop productivity and sustainability.

3. What Material is Used for Canal Lining?

Canal lining is a crucial measure employed to prevent water flow through the bed and sides of a canal. Various materials can be utilized for constructing canal linings, including geomembrane canal liners, cement, bricks, boulders, plastics, compacted earth, and concrete. Among these options, geomembrane canal liners have emerged as a cost-effective and widely adopted choice for canal lining.

Geomembrane canal liners are synthetic membranes made from materials like high-density polyethylene (HDPE), low-density polyethylene (LDPE), or polyvinyl chloride (PVC). These liners are designed to create an impermeable barrier that resists water seepage and effectively controls water flow within the canal.

One of the primary reasons for the popularity of geomembrane canal liners is their cost-effectiveness. Compared to traditional materials like cement, bricks, or boulders, geomembrane liners offer a more economical solution for canal lining without compromising on performance. Not only are they relatively inexpensive to procure, but they also require less labor and time for installation.

Geomembrane canal liners provide a highly efficient barrier against water seepage due to their excellent impermeability. They are specifically engineered to have low permeability coefficients, ensuring minimal water loss and maximum water conservation within the canal system. This translates to improved water resource management and enhanced overall irrigation efficiency.

Geomembrane canal liners offer several other benefits. They are lightweight, flexible, and easy to transport, making them convenient to work with during installation. These liners also exhibit high chemical resistance, UV resistance, and durability, ensuring long-term performance and minimal maintenance requirements.

4. Why Choose BPM Geomembrane Canal lining for Water Channel Project In Mumbai

Our customer in Mumbai sought our assistance with a canal lining project to address seepage issues around a golf course. The golf course was built on well-drained soil, causing water from the lakes to seep out during the summer months when water was most needed for the lawns. To combat this problem, our customer required a seepage control solution using a geomembrane liner for canal lining.

In response to their request, we promptly provided samples of our HDPE geomembrane liner and comprehensive product information. We explained to the customer why HDPE geomembrane is renowned for its excellent anti-seepage performance, leading to its growing popularity in preventing pond seepage. The key lies in our use of non-toxic, tasteless, and odorless particles as raw materials, with a melting point ranging from 110°C to 130°C and a relative density between 0.918 and 0.965. These materials offer exceptional chemical stability, high rigidity, toughness, mechanical strength, and resistance to environmental stress cracking and tearing. As a result, our geomembrane effectively controls seepage.

After two weeks, the customer confirmed the quality of our HDPE geomembrane and expressed satisfaction. They proceeded to sign the order contract and construction agreement promptly, indicating their trust in our product and their readiness to move forward with the project.

By choosing BPM Geomembrane for their canal lining needs, our customer in Mumbai will benefit from an effective seepage control solution. They can prevent water loss and ensure that the golf course’s water requirements are met, even during the dry summer months. Our high-quality HDPE geomembrane liner will provide a reliable and durable barrier, minimizing seepage and optimizing water utilization.

We take pride in our ability to provide timely and efficient solutions to our customers’ specific requirements. With our geomembrane products and expertise, we aim to assist customers in enhancing their infrastructure projects, ensuring long-term success and satisfaction.

5. Specifications of Canal Lining Anti-seepage Geomembrane

- Thickness: 0.5mm

- Specifications :200 g/0.5 mm/200 g, a 6×50 meter/piece

- Total: 50,000 square meters

6. About BPM

BPM had exported many types of effective and states of the art geomembranes, geotextile and other geosynthetics to over 36 countries. We are also providing professional design and installation service. OEM and ODM are also available.

If you have any questions or inquiries, please contact us, we will reply as soon as possible.