CASE STUDY

- Location – South Africa

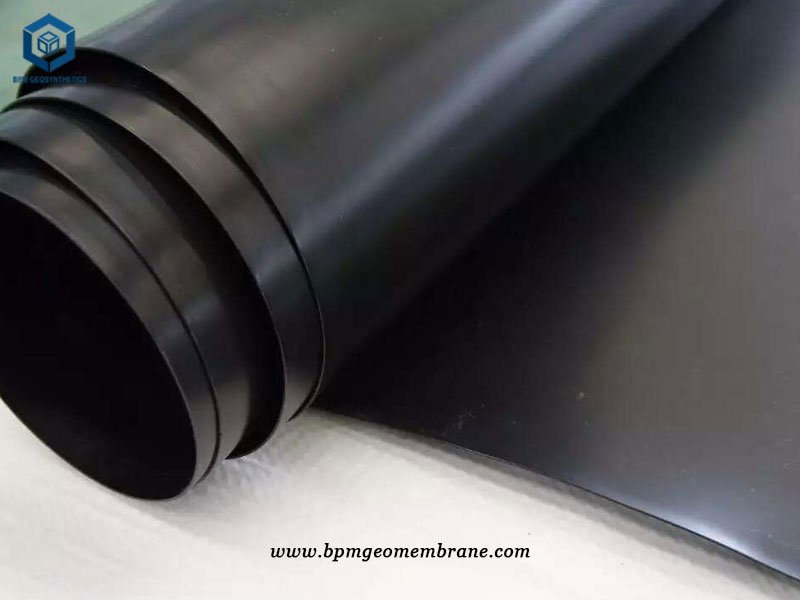

- Product(s) – HDPE Landfill Plastic Liner

- Application – Mining Project

Issue

An important issue for landfills is leachate contamination control. After the landfill starts, the inflow of rainwater, surface water and the decomposition of the garbage itself will produce a large amount of sewage, which we call leachate. This liquid pollutant is high in content, complex in composition and fast infiltrating into the ground, which will cause serious pollution to groundwater for hundreds of years.

Solution

In landfill systems, the HDPE geomembrane liner is crucial. It acts as the main barrier against leaks. High-quality resin and production techniques ensure a strong anti-seepage wall.

HDPE geomembrane offers great value for sealing landfills. Made from high-density polyethylene, it’s tightly sealed. This stops flies and insects while preventing bacteria growth. It keeps bad smells contained within the landfill.

This geomembrane liner prevents water seepage too. On top of blocking flies and odors, it also stops rainwater and dew from entering the landfill.

With a long lifespan, the geomembrane excels in durability. Buried underground, it lasts over 50 years. Even exposed to the elements, its life reaches 50 years.

BPM’s South African client embarked on a large landfill project, aiming to manage leachate effectively. BPM advised on HDPE liner specifications and offered installation guidance.

For the HDPE geomembrane trench, follow these rules:

- Trench edge to slope: at least 800mm gap.

- No right angles; arcs preferred in design.

- Staggered ditch cross-section based on paving style.

- Undisturbed subsoil during groove excavation.

- Trench bottom flat, free of loose dirt.

- Design-compliant depth and slope walls.

- Prevent flooding before backfilling.

- Timely backfill with quality assurance.

Landfill cover system layers (top to bottom):

- Exhaust layer: Ensure gas pressure <0.75kPa. Use 25-50mm coarse material, permeability >1×10^-2cm/s, min 30cm thick. Alternative: geocomposite net.

- Anti-seepage layer: Combine geomembrane and geotextile for impermeability. Choose HDPE or LLDPE >0.75mm thick, permeability <1×10^-7cm/s. Geotextiles needed on both sides.

Benefits

(1) Geomembrane landfill plastic liner can reduce the infiltration of rainwater and other external water into the garbage heap, and achieve the purpose of reducing landfill leachate;

(2) The landfill plastic liner can control the odor emission of the landfill and the release and collection of combustible gas from the upper part of the landfill in an organized manner to achieve the purpose of pollution control and comprehensive utilization;

(3) The landfill liner can inhibit the reproduction and spread of pathogenic bacteria and their communicators, mosquitoes and flies;

(4)The geomembrane landfill liner can prevent surface runoff from being polluted, avoid the spread of garbage and its direct contact with humans and animals;

(5) The geomembrane landfill liner can prevent soil erosion;

(6) The geomembrane landfill liner can promote the stabilization of the garbage heap as soon as possible;

(7) The geomembrane landfill plastic liner can provide a surface that can be landscaped, provide soil for the growth of vegetation, facilitate the reuse of landfill land, etc.

Summary

HDPE geomembrane geomembrane landfill liner is a kind of waterproof barrier material based on high polymer polymer. HDPE geomembrane is made of high-quality virgin resin, the main component is 97.5% high density, about 2.5% carbon black, anti-aging agent, antioxidant, ultraviolet absorber, stabilizer and other auxiliary materials.

The HDPE landfill liner has good resistance to environmental stress cracking and chemical corrosion resistance, good chemical corrosion resistance. It also has a large operating temperature range and a long service life, and is widely used in biogas digesters, tailings storage sites, and channel seepage prevention , Dam seepage prevention subway project, etc.

Specifications of Landfill Plastic Liner for Mining Project in South Africa

- Total HDPE Geomembranequantity – 98,000 squares meters

- Geomembrane Specifications– 2mm

- Each roll size is 7m*50m

About BPM

BPM has been specializing in delivering one stop geosynthetics products and solutions to worldwide customers since its foundation in 2007. BPM had provided many types of effective and state of the art geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids to over 81 countries. Our main customers are from Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia, etc.

BPM is not only manufacturing best quality geosynthetic products but also providing professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.