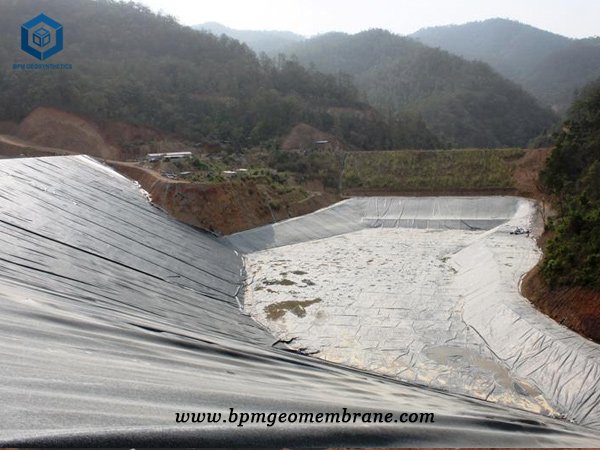

BPM Peru received a request from a customer to purchase HDPE pond liners and other geosynthetic products for an anti-seepage lining tailings treatment project. Peru’s mining and petrochemical energy industries are well-developed, leading to an increased demand for mineral products and a subsequent increase in beneficiation tailings. Proper treatment of tailings is crucial to address environmental and economic concerns.

The treatment method of tailings is generally as the filling material of the underground mining goaf of the mine, that is, the water-sand filling material or the aggregate of cemented filling; perhaps some of them are directly covered with soil on the tailings accumulation site to cultivate crops or plant trees. In fact, the most economical way to deal with tailings is still sand making from tailings and materials used as building materials. For example, the treated tailings can be used as cement, tile, aerated concrete, permeable bricks, fire-resistant materials, fire-proof insulation materials, and glass. Ceramsite, concrete aggregate and other materials, tailings sand can replace part of the machine-made sand to make concrete, build roads, road materials, etc.

The advantage of using geomembrane pondliner for tailings dams is that when tailings contain toxic or radioactive substances or heavy metal ions, in principle it is not allowed to contain harmful substances to pollute the groundwater, so seepage prevention treatment is required.

What is The BPM Textured HDPE Pondliner?

As the leading geosynthetic products manufacturer and wholesaler, The Best Project Material Co., Ltd (BPM) has dedicated to manufacturing and supplying one stop geosynthetic solutions and services to worldwide customers since its foundation in 2010. We have over 120 professional staff and 16,000 square meters manufacturing factory equipped with state of the art production lines. Our innovative, high quality geosynthetic solutions include geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids, etc. All BPM brand geosynthetic products have been pass the certificates of ISO9001, ISO14001, Soncap, SASO, BV and passed the test of SGS and Intertek etc.As a waterproofing liner, HDPE geomembrane pond liner is favored over other materials for its modest economic and operational advantage. Economically, HDPE geomembrane pondliner is superior thanks to its relatively straightforward manufacturing process, which has driven up supply and kept prices low in contrast to other kinds of geomembranes.

Furthermore, hdpe geomembrane pondliner is a very stable polyolefin that is chemically inert and able to maintain long-term integrity and durability. These properties make the HDPE membrane a popular choice to waterproof and mining, landfill and other containment applications.

Why Chose Textured HDPE Pondliner Peru for Tailings Treatment Project?

BPM Textured geomembrane podnliner is produced by the spray texture technology. It is designed with one or two side textured surface. Except for the excellent properties of smooth geomembrane, it also has better interface friction coeffcient and UV resistance. This increased the slope stability and skid resistance which fit for steep slope or vertical geotechnical projects such as mining.

We recommended the 2mm textured geomembrane pond liner and 400g PP geotextile to the customer. Through communication, the customer finally chose the 1.5mm textured geomembrane and 270g PP geotextile. We sent the customer product pictures, production videos, and certification certificates etc, and communicate product details with customers.

But the customer needs to increase the rough surface height based on the American standard. We will communicate the customer’s requirements with the production department, and test according to the customer’s specifications and indicators, produce two pcs of 2m*2m samples, and samples.After the customers received them, they immediately arranged to go to the local laboratory for testing. Our products fully met the requirements and finally reached a cooperation.

Specifications of Textured Geomembrane HDPE Pondliner for Tailings Treatment Project

- Total textured geomembrane quantity –52,150m2

- Geomembranespecification – 1.5mm

- Each roll size is 7m*50m

We sent the production schedule to the customer, test each batch of products, and feedback the test data to the customer in time, so that the customer can know more about the production situation and product quality at any time.

About BPM

As the the professional geomembrane manufacturer and supplier, BPM has been dedicated to supplying one stop geomembranes and services to worldwide customers since its foundation in 2010. Our main innovative, high quality geosynthetics products include geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids, etc. All BPM brand HDPE geomembranes have passed the certificates of the ISO9001, ISO14001, TUV, Soncap, SASO, BV certificates and the test of SGS and Intertek etc. Our geomembrane products have been exported to over 36 countries. If you have any questions or inquiries, please contact us.