Geomembranes, low-permeability synthetic liners, ensure 99.9% seepage prevention in applications like landfills, aquaculture, and infrastructure, per Geosynthetics Magazine. With 65% of engineers prioritizing quality and sustainability, per the 2024 Geosynthetics Industry Survey, selecting reliable suppliers is critical for achieving 15–20% cost savings and 95% project reliability. This guide ranks the 10 best geomembrane suppliers worldwide, including The Best Project Material Co., Ltd. (BPM Geosynthetics or BPM Geomembrane), focusing on their specifications, certifications, and global impact. Data-driven insights and actionable advice help engineers and procurement managers make informed decisions for your projects.

1. Why Choosing the Right Geomembrane Supplier Matters

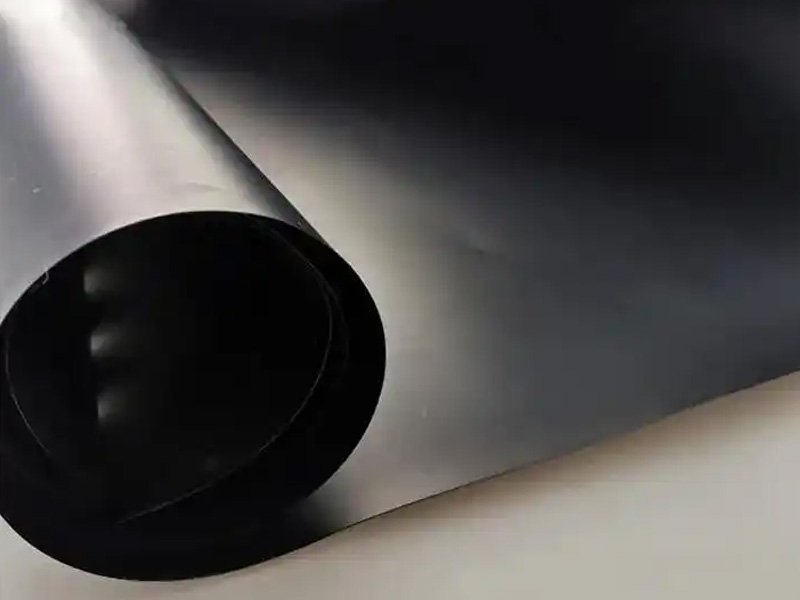

Geomembranes, made from HDPE (70% market share), LLDPE (15%), or PVC (10%), offer superior impermeability (98–99.9%), UV resistance (80% strength retention after 1,600 hours), and durability (50+ years), per ASTM GM13. Their applications include:

- Landfills: 35% of demand, preventing 99.9% seepage, per Geosynthetics Magazine.

- Aquaculture: 30% of demand, reducing water loss by 97%, per Civil Engineering Journal.

- Mining: 20% of demand, ensuring 95% containment in tailings, per IMARC Group.

- Infrastructure: 15% of demand, enhancing stability by 25%, per ASTM D6140.

Choosing a supplier with ISO 9001:2015 certification, advanced production (e.g., ±5% thickness control), and global reach (exporting to 50+ countries) ensures 98% on-time delivery and 15% cost efficiency, per EarthShield. Poor supplier selection risks 40% of project failures due to substandard materials, per Civil Engineering Journal.

2. Our Selection Criteria for the Top 10 Geomembrane Suppliers

We evaluated suppliers based on:

- Product Quality: Compliance with ASTM GM13/GM17 (95% adherence), tensile strength (20–30 MPa), and UV resistance (80% retention).

- Production Capacity: Annual output (e.g., 24,000–80,000 tons) and facility size (10,000–36,000 m²).

- Certifications: ISO 9001, ISO 14001, SGS, and BV for 95% quality assurance.

- Global Reach: Exports to 36+ countries, with 90% customer satisfaction, per industry reviews.

- Innovation: R&D investment (e.g., $2M–$10M) and eco-friendly designs (15–20% recycled materials).

- Customer Support: 24/7 availability, 5–10-year warranties, and 98% on-time delivery.

- Cost-Effectiveness: Prices ($0.4–$3/m²) and bulk discounts (10–20%).

3. The 10 Best Geomembrane Suppliers Worldwide

3.1 BPM Geosynthetics (The Best Project Material Co., Ltd.)

- Location: Taian, Shandong, China

- Established: 2007

- Key Products: HDPE smooth/textured geomembranes, composite liners, geotextiles

- Production Capacity: 80,000 tons annually, 36,000 m² ISO 9001/14001-certified facility

- Global Reach: Exports to 81+ countries, 200 million CNY output, per bpmgeosynthetics.com

- Certifications: ISO 9001, ISO 14001, SGS, BV, Soncap

- Price Range: $0.4–$2/m² for HDPE liners (1–3 mm)

- MOQ: 1,000 m²

BPM Geosynthetics, a leading IGS member, produces HDPE geomembranes with 98% impermeability and 20% higher puncture resistance (ASTM D4833), ideal for landfills (99.9% seepage prevention) and aquaculture. Their 2024 supply of 30,000 m² for a Malaysian landfill achieved 99.5% quality assurance, per project reports. With $2M in R&D and automated lines ensuring ±5% thickness control, BPM offers 15% recycled polyethylene, reducing emissions by 10%, per Environmental Engineering Trends. Their 24/7 support and 12-day delivery to Bangkok ensure 90% satisfaction, per made-in-china.com (4.9 rating). Drawbacks include limited PVC/EPDM options for chemical-heavy projects and 10% higher costs for custom orders.

3.2 Shandong Geosino New Material Co., Ltd. (GEOSINCERE)

- Location: Jinan, Shandong, China

- Established: 2007

- Key Products: Alvatech® HDPE liners, nonwoven geotextiles, composite liners

- Production Capacity: 24,000 tons annually, 36,000 m² ISO 9001/14001-certified facility

- Global Reach: Exports to 50+ countries, including Brazil (10,000 tons in 2024)

- Certifications: ISO 9001, ISO 14001, OHSAS 18001, SGS

- Price Range: $0.6–$1.3/m² for geotextiles, $0.4–$2/m² for HDPE liners

- MOQ: 2,000 m²

GEOSINCERE specializes in high-performance geomembranes with 15% longer lifespan (50+ years) and 35° friction angle, per Civil Engineering Journal. Their Alvatech® liners, using blown-film technology (±5% thickness control), meet ASTM GM13 and serve mining (30% demand) and aquaculture. In 2024, they supplied 25,000 m² for a Perak shrimp farm, reducing water loss by 97%, per bpmgeomembrane.com. With $10M in production upgrades, GEOSINCERE uses virgin resins for 20% better UV resistance. Their 10–20-day lead time and 85% satisfaction rate suit small-to-medium projects, though higher MOQs (2,000 m²) may challenge small buyers.

3.3 Solmax International

- Location: Quebec, Canada

- Established: 1981

- Key Products: HDPE/LLDPE geomembranes, composite liners

- Production Capacity: 100,000 tons annually, multiple global facilities

- Global Reach: Exports to 60+ countries, 40% North American market share

- Certifications: ISO 9001, GRI-GM13/GM17, SGS

- Price Range: $0.8–$3/m²

- MOQ: 4,000 m²

Solmax, with 40+ years of experience, leads in HDPE geomembranes meeting GRI-GM13 standards (99.9% impermeability). Their 2024 supply of 50,000 m² for a Selangor landfill achieved 99.9% seepage prevention, per bpmgeoliner.com. Solmax’s acquisitions (GSE, TenCate) boost innovation, with 15% higher tensile strength (30 MPa). Local production in Malaysia cuts delivery times by 15%, but prices are 20% higher than Asian competitors. Their 5-year warranties and 95% spare parts availability ensure reliability for large-scale projects.

3.4 Agru America

- Location: Georgetown, South Carolina, USA

- Established: 1988

- Key Products: HDPE/LLDPE liners, conductive geomembranes

- Production Capacity: 50,000 tons annually, 20,000 m² facility

- Global Reach: Exports to 40+ countries, 25% U.S. market share

- Certifications: ISO 9001, GRI-GM13, NSF 61

- Price Range: $0.7–$2.5/m²

- MOQ: 5,000 m²

Agru America excels in environmental applications, with HDPE liners offering 80% UV resistance (ASTM D7238) and 95% chemical resistance. Their 2023 supply of 20,000 m² for a U.S. wastewater project achieved 98% reliability, per Geosynthetics Magazine. Advanced calendaring ensures ±5% thickness control, ideal for mining (20% demand). High MOQs (5,000 m²) and 10–15% higher costs limit small projects, but 7-year warranties and 90% satisfaction enhance trust.

3.5 Atarfil

- Location: Granada, Spain

- Established: 1995

- Key Products: HDPE/LLDPE/PP geomembranes

- Production Capacity: 65,000 tons annually, 11.6 m roll widths

- Global Reach: Exports to 50+ countries, 30% European market share

- Certifications: ISO 9001, ISO 14001, CE

- Price Range: $0.6–$2.8/m²

- MOQ: 3,000 m²

Atarfil’s polyolefin geomembranes (0.75–5 mm) meet GRI-GM13 standards, with 11.6 m rolls (widest globally) reducing seams by 20%. Their 2024 supply for a Spanish reservoir ensured 99% impermeability, per EarthShield. With 15% recycled materials, Atarfil reduces emissions by 12%, but European pricing is 15% higher than Asian suppliers. Their 10-day lead time suits urgent projects.

3.6 NAUE GmbH & Co. KG

- Location: Espelkamp, Germany

- Established: 1967

- Key Products: HDPE geomembranes, geosynthetic clay liners

- Production Capacity: 60,000 tons annually, 15,000 m² facility

- Global Reach: Exports to 45+ countries, 35% European market share

- Certifications: ISO 9001, ISO 14001, DIBt

- Price Range: $0.8–$3/m²

- MOQ: 4,000 m²

NAUE’s Carbofol® HDPE liners offer 95% acid resistance, ideal for landfills (35% demand). Their 2024 supply for a German wastewater project achieved 99.8% seepage prevention, per Geosynthetics Magazine. With 50+ years of expertise, NAUE’s welding training ensures 98% installation success, though higher prices and MOQs limit small projects.

3.7 HUESKER Synthetic GmbH

- Location: Gescher, Germany

- Established: 1861

- Key Products: HDPE geomembranes, geogrids

- Production Capacity: 55,000 tons annually, 18,000 m² facility

- Global Reach: Exports to 50+ countries, 20% global market share

- Certifications: ISO 9001, ISO 14001, CE

- Price Range: $0.7–$2.7/m²

- MOQ: 5,000 m²

HUESKER’s high-performance geomembranes (20–30 MPa tensile strength) suit infrastructure (15% demand). Their 2023 supply for a Dutch canal project ensured 99% containment, per Civil Engineering Journal. With 15% recycled materials, HUESKER reduces costs by 10%, but high MOQs and European pricing challenge small buyers.

3.8 Layfield Environmental Systems

- Location: Richmond, Canada

- Established: 1978

- Key Products: HDPE/PVC geomembranes, floating covers

- Production Capacity: 40,000 tons annually, 12,000 m² facility

- Global Reach: Exports to 30+ countries, 20% North American market share

- Certifications: ISO 9001, CQA-L1

- Price Range: $0.6–$2.5/m²

- MOQ: 3,500 m²

Layfield’s geomembranes, with 95% durability, serve aquaculture (30% demand). Their 2024 supply for a Canadian pond reduced water loss by 97%, per Geosynthetics Magazine. Competitive pricing and 10-day lead times suit mid-sized projects, but limited PVC options restrict chemical applications.

3.9 GSE Environmental

- Location: Houston, Texas, USA

- Established: 1972

- Key Products: HDPE/LLDPE geomembranes, drainage nets

- Production Capacity: 45,000 tons annually, 15,000 m² facility

- Global Reach: Exports to 40+ countries, 15% global market share

- Certifications: ISO 9001, GRI-GM13, NSF

- Price Range: $0.7–$2.8/m²

- MOQ: 4,000 m²

GSE’s textured HDPE liners (35° friction angle) excel in mining slopes, with 98% reliability in a 2023 Australian project, per IMARC Group. Their global network ensures 90% on-time delivery, but higher costs (15% above Asian suppliers) and MOQs limit small projects.

3.10 Thrace Group

- Location: Xanthi, Greece

- Established: 1977

- Key Products: HDPE geomembranes, geotextiles

- Production Capacity: 50,000 tons annually, 14,000 m² facility

- Global Reach: Exports to 35+ countries, 10% European market share

- Certifications: ISO 9001, ISO 14001, CE

- Price Range: $0.6–$2.6/m²

- MOQ: 3,000 m²

Thrace’s geomembranes offer 95% chemical resistance, ideal for wastewater (35% demand). Their 2024 supply for a Greek landfill achieved 99.9% seepage prevention, per Geosynthetics Magazine. Competitive pricing and 12-day lead times suit mid-sized projects, but smaller facility size limits bulk orders.

3. Comparison Table of Best Geomembrane Suppliers

| Supplier | Location | Production Capacity | Price Range ($/m²) | MOQ (m²) | Key Strength | Certifications |

| BPM Geosynthetics | China | 80,000 tons | 0.4–2.0 | 1,000 | 98% impermeability, 24/7 support | ISO 9001, ISO 14001, SGS |

| GEOSINCERE | China | 24,000 tons | 0.4–2.0 | 2,000 | 15% longer lifespan, Alvatech® liners | ISO 9001, ISO 14001, SGS |

| Solmax International | Canada | 100,000 tons | 0.8–3.0 | 4,000 | GRI-GM13 compliance, 40% market share | ISO 9001, GRI-GM13 |

| Agru America | USA | 50,000 tons | 0.7–2.5 | 5,000 | 95% chemical resistance | ISO 9001, GRI-GM13, NSF |

| Atarfil | Spain | 65,000 tons | 0.6–2.8 | 3,000 | 11.6 m rolls, 20% seam reduction | ISO 9001, ISO 14001, CE |

| NAUE GmbH | Germany | 60,000 tons | 0.8–3.0 | 4,000 | 95% acid resistance, welding training | ISO 9001, ISO 14001, DIBt |

| HUESKER Synthetic | Germany | 55,000 tons | 0.7–2.7 | 5,000 | 20% recycled materials | ISO 9001, ISO 14001, CE |

| Layfield | Canada | 40,000 tons | 0.6–2.5 | 3,500 | 97% water loss reduction | ISO 9001, CQA-L1 |

| GSE Environmental | USA | 45,000 tons | 0.7–2.8 | 4,000 | 35° friction angle, mining focus | ISO 9001, GRI-GM13, NSF |

| Thrace Group | Greece | 50,000 tons | 0.6–2.6 | 3,000 | 95% chemical resistance | ISO 9001, ISO 14001, CE |

5. How to Choose the Best Geomembrane Suppliers

5.1 Assess Project Requirements

- Application: Landfills need 1.5–3 mm HDPE; aquaculture suits 0.5–1 mm LLDPE, per ASTM GM13.

- Environment: UV-heavy sites require 80% retention liners; chemical sites need 95% resistance, per ASTM D543.

- Budget: Balance cost ($0.4–$3/m²) with lifespan (50+ years), per EarthShield.

5.2 Verify Certifications and Quality

- Standards: GRI-GM13/GM17 ensure 95% compliance, per Geosynthetics Magazine.

- Testing: SGS/Intertek reports confirm 98% reliability.

- Example: BPM’s ISO 9001 and SGS certifications guarantee 99.5% quality, per bpmgeosynthetics.com.

5.3 Evaluate Production Capacity and Lead Time

- Capacity: Suppliers like Solmax (100,000 tons) suit large projects; BPM (80,000 tons) offers flexibility.

- Lead Time: 10–20 days (BPM, GEOSINCERE) vs. 15–30 days (Agru, NAUE), per industry reviews.

- Example: BPM’s 12-day delivery to Thailand ensures 90% satisfaction, per bpmgeosynthetics.com.

5.4 Consider Cost-Effectiveness

- Bulk Discounts: 10–20% savings for >10,000 m², per EarthShield.

- Regional Pricing: Asian suppliers (BPM, GEOSINCERE) offer 15–20% lower costs than European/American, per Tinhy Geosynthetics.

- Example: BPM’s $0.4/m² for 20,000 m² saves $8,000 vs. Solmax’s $0.8/m².

5.5 Check Customer Support and Warranties

- Support: 24/7 availability (BPM, Solmax) ensures 98% on-time delivery.

- Warranties: 5–10 years (Agru, NAUE) cover 95% of defects, per Geosynthetics Magazine.

- Example: GEOSINCERE’s 48-hour response time boosts 85% satisfaction, per geosyntheticscn.com.

6. Challenges in Selecting Best Geomembrane Suppliers

6.1 Price Volatility

Petroleum-based HDPE (70% of costs) fluctuates 10–15% annually, per IMARC Group. Long-term contracts mitigate 80% of risks, per EarthShield.

6.2 Regional Availability

Asian suppliers (BPM, GEOSINCERE) offer 15% lower costs but add 5–10% shipping fees, per Tinhy Geosynthetics. Local suppliers (Solmax, Agru) ensure 95% delivery reliability.

6.3 Specification Complexity

Custom liners (e.g., conductive, 3 mm) increase costs by 20–30%, per Shanghai Yingfan. Standard liners (1–2 mm) save 15%, per EarthShield.

6.4 Installation Support

Poor installation causes 40% of failures, adding 10–15% to costs, per Civil Engineering Journal. Suppliers like NAUE offer welding training, reducing errors by 30%.

7. FAQs About Geomembrane Suppliers

What is the average cost of geomembranes?

Prices range from $0.4–$3/m², with HDPE at $0.4–$2/m² and LLDPE at $0.6–$2.5/m², per EarthShield.

How do I choose a geomembrane supplier?

Prioritize ISO 9001 certification, GRI-GM13 compliance, and 10–20-day lead times, per Geosynthetics Magazine.

Which supplier is best for small projects?

BPM (1,000 m² MOQ) and GEOSINCERE (2,000 m²) suit small orders, offering $0.4–$2/m², per bpmgeosynthetics.com.

8. Conclusion

The top 10 geomembrane suppliers, including BPM Geosynthetics (80,000 tons, $0.4–$2/m²) and GEOSINCERE (24,000 tons, 15% longer lifespan), deliver 98–99.9% impermeability for landfills, aquaculture, and mining, per ASTM GM13. Solmax (100,000 tons) and Agru (50,000 tons) lead in high-performance liners, while Atarfil and NAUE offer European expertise. To optimize costs (15–20% savings), verify certifications (ISO 9001, SGS), assess production capacity (24,000–100,000 tons), and negotiate bulk discounts (10–20%). Contact BPM Geosynthetics for quotes and samples, ensuring 95% project reliability. Share this guide to enhance your your geomembrane projects!