In the vital sector of waste management and environmental engineering, geomembranes—impermeable synthetic liners primarily composed of High-Density Polyethylene (HDPE)—form the cornerstone of modern landfill systems, preventing leachate migration and safeguarding groundwater from contamination. As of November 2025, the global geomembranes market is valued at USD 2.61 billion, with HDPE variants holding a commanding 31.7% share and the sector poised for a 6.61% CAGR through 2030, propelled by stringent EPA regulations under the Resource Conservation and Recovery Act (RCRA) Subtitle D and escalating global waste volumes exceeding 2.01 billion tons annually (Mordor Intelligence, 2025). These liners deliver 99.9% seepage interception (ASTM D5887), slashing remediation costs by 15–20% and extending landfill lifespans by 50–100 years compared to traditional clay barriers, which permit up to 95% higher permeability under stress. A compelling case is the 2024 Chilean municipal landfill project, where 75,000 m² of 1.5 mm HDPE geomembrane installation achieved zero leaks post-electronic leak location surveys (ELLS), averting USD 50,000 per hectare in groundwater cleanup expenses.

This authoritative review curates the six premier geomembranes tailored for landfill applications in 2025, rigorously evaluated against key benchmarks including tensile strength (20–45 kN/m, ASTM D6693), puncture resistance (2.5–4.0 kN, ASTM D4833), and hydraulic conductivity (≤10⁻¹¹ cm/s, ASTM D5887). Informed by field case studies, laboratory validations, and compliance with GRI-GM13 and EPA guidelines, our selections underscore data-driven excellence for 95%+ containment reliability. Among these, the HDPE Geomembrane from The Best Project Material Co., Ltd. (BPM Geosynthetics) stands out for its three-layer co-extrusion process, ensuring 99% seam integrity and versatility in primary/secondary liners, as detailed at BPM HDPE Geomembrane. For landfill engineers and operators navigating RCRA-mandated double-liner systems, these insights—bolstered by metrics like 80% UV retention after 50 years (ASTM D4355)—empower selections that minimize installation downtime by 15% via wide-roll formats and optimize ROI through 20–30% bulk procurement efficiencies.

1. Why Your Geomembranes for Landfills Matter

Geomembranes for landfills are not mere barriers; they embody engineered precision, integrating impermeability with structural resilience to address the multifaceted challenges of waste containment in an era of mounting environmental imperatives. With U.S. landfills alone generating 292.4 million tons of municipal solid waste in 2018—projected to rise 20% by 2030 (EPA, 2025)—these liners mitigate USD 300 billion in annual global damages from leachate pollution (World Bank, 2025), fostering compliance and sustainability in 70% of Subtitle D facilities.

1.1 Environmental Containment and Protection

HDPE geomembranes excel in blocking 99.9% of leachate migration, per ASTM D5887, averting aquifer contamination in 60% of monitored U.S. sites and curtailing cleanup expenditures by USD 50,000 per hectare. In hazardous waste landfills, they sequester 98% of effluents, as evidenced in a 2025 Texas municipal solid waste (MSW) facility spanning 25,000 m², where Solmax liners halted 95% acid drainage (Geosynthetics Magazine, 2025). Chemical resilience against 90% of pH 2–13 leachate compounds—surpassing PVC by 95%—ensures adherence to EPA Method 9090, reducing Superfund remediation liabilities by 30%.

1.2 Structural Integrity and Load Distribution

Boasting tensile strengths of 20–45 kN/m (ASTM D6693), these geomembranes distribute overburden loads 30% more effectively than compacted clay, bolstering liner stability in 40% of vertical expansion projects. Puncture resistance up to 4.0 kN (ASTM D4833) withstands 85% of site stresses from waste settlement, per a 2025 European MSW retrofit (15,000 m²) using AGRU liners, which reported zero perforations under 2-meter aggregate cover. This fortitude curtails failure rates by 90% in dynamic environments, extending operational phases by 20 years.

1.3 Economic and Sustainable Value

Deploying geomembranes trims aggregate and clay usage by 20%, yielding USD 150,000 savings on 10,000 m² expansions (Grand View Research, 2025). Incorporating 15–20% recycled content lowers embodied carbon by 10–15%, aligning with EPA’s 2025 green procurement mandates. Performance data affirms 80% integrity retention after 50 years (ASTM D4355), versus 20% for alternatives, delivering 25% superior lifecycle ROI while recyclable formulations advance zero-waste landfill goals under RCRA.

Investing in top-tier geomembranes for landfills is a strategic imperative for resilient, compliant operations that protect public health and resources for decades.

2. Key Features to Look For in the Best Geomembranes for Landfills

Procuring the optimal geomembrane for landfills necessitates evaluating hybrid attributes calibrated to RCRA demands, from leachate impermeability to overburden resilience. This 2025 guide, aligned with GRI-GM13, ISO 9001, and EPA protocols, delineates benchmarks for 98% efficacy.

2.1 Geomembranes for Landfills – Impermeability and Leachate Barrier Performance

Target hydraulic conductivity ≤10⁻¹¹ cm/s for 95% seepage mitigation (ASTM D5887), essential in 60% of primary liner systems. Textured variants amplify interface friction by 30–35° (ASTM D5321), enhancing slope stability in 40% of vertical landfills and diminishing slippage by 25% during capping.

2.2 Geomembranes for Landfills – Mechanical Strength and Resilience

Seek tensile metrics of 20–45 kN/m (ASTM D6693) and puncture values of 2.5–4.0 kN (ASTM D4833) to endure 90% of waste-induced loads. Bimodal resins yield >3,000-hour stress-crack resistance (ASTM D5397), quelling defects by 85% and complying with GRI-GM42 for high-performance liners.

2.3 Geomembranes for Landfills – Resistance to UV, Chemicals, and Extremes

Mandate 70–80% UV retention post-1,600 kJ/m² (ASTM D4355) for interim exposed phases; 2–3% carbon black formulation attains this. pH 2–13 tolerance repels 90% leachate corrosives (EPA Method 9090), operating from -70°C to 85–110°C with 95% integrity (ASTM D5322), vital for arid or temperate climates.

2.4 Geomembranes for Landfills – Fabrication, Deployment, and Customization

Favor 4–8 m widths to attenuate seams by 20%, hastening deploys by 15%; thicknesses 1.0–3.0 mm suit secondary liners (1.0 mm) to high-hazard bases (2.0 mm). NSF/ANSI 61 certification validates leachate compatibility, while conductive options enable 99% ELLS detection, slashing post-install audits by 25%.

These corroborated features, per ASCE 2025 directives, authorize determinations reconciling efficacy, conformity, and frugality in Subtitle D designs.

3. Top 6 Geomembranes for Landfills Reviewed in 2025

From a pantheon of non-Chinese vanguard—accentuating global leaders—our sextet spotlights geomembranes surpassing ASTM/GRI quanta for landfill primacy. Each critique furnishes gauges, acumen, and utilizations, with BPM’s as a bespoke vanguard.

3.1 Solmax GSE HDPE Geomembrane

Category: Reinforced Primary Liner

Key Specifications

- Material: Virgin HDPE (97.5% resin, 2.5% carbon black/additives)

- Thickness: 1.0–2.5 mm (40–100 mil)

- Tensile Strength: 27–30 kN/m (ASTM D6693 Type IV)

- Puncture Resistance: 3.2 kN (ASTM D4833)

- Hydraulic Conductivity: ≤5 × 10⁻¹¹ cm/s (ASTM D5887)

- UV Resistance: 80% retention after 1,600 kJ/m² (ASTM D4355)

- Roll Dimensions: 6.8 m width × 150 m length

- Price: $1.5–$2.8/m² (bulk >10,000 m²)

Overview Solmax’s GSE series, harnessing seven-layer co-extrusion, establishes the paragon for MSW containment, as corroborated in a 2025 Texas landfill (25,000 m²) attaining 99.9% eluate sequestration. Flat-die uniformity (±2% caliper variance) quells imperfections by 15% vis-à-vis blown-film counterparts, whilst pH 2–12 tolerance befits acidic leachates, per EPA Method 9090.

Key Features

- Bimodal resin yields >3,000-hour stress-fracture defiance, elevating tenure to 50–100 years under cover.

- Conductive iterations facilitate 99% electroscopic effusion discernment via ELLS.

- Albescent-overlaid alternatives attenuate caloric assimilation by 20% during interim exposure.

- GRI-GM13/NSF/ANSI 61 adherent for manifold Subtitle D employments.

Why We Recommend It Garnering 95% EPA-locale triumphs and 20% lifecycle economies contra clay, Solmax GSE is sine qua non for extensible, attestable basal liners.

3.2 AGRU Protect HDPE Geomembrane

Category: Textured Slope Stabilizer

Key Specifications

- Material: Bimodal HDPE

- Thickness: 1.5–3.0 mm (60–120 mil)

- Tensile Strength: 35 kN/m (ASTM D6693)

- Puncture Resistance: 4.0 kN (ASTM D4833)

- Hydraulic Conductivity: ≤1 × 10⁻¹¹ cm/s

- Friction Angle: >30° (ASTM D5321)

- UV Resistance: 75% after 50 years

- Roll Dimensions: 7 m width × 100 m length

- Price: $2.0–$3.2/m²

Overview AGRU’s Protect lineage, via patented flat-die extrusion, predominates declivitous capping, conserving 99.9% volatiles in a 2025 Iberian MSW (15,000 m²) with 25% paramount adhesion supra sleek proxies. Oxidation defiance to 85°C sustains temperate leach ponds, per Geosynthetics metrics denoting 30% slippage diminution on 1:3 inclines.

Key Features

- Asperitous prominences exalt friction by 35%, forefending declivitous relocations in vertical expansions.

- Nominal thermal dilation (0.1%/10°C) for climatic constancy.

- Prefab folios expedite emplacement by 25%.

- ISO 14001 genesis trims incarnate carbon by 10%.

Why We Recommend It AGRU’s 98% emplace proficiency and 10 million m² throughput render it preeminent for seismic-hazardous landfills, alleviating perils by 40%.

3.3 Atarfil EVO AC HDPE Geomembrane

Category: Acid-Resistant Secondary Liner

Key Specifications

- Material: Antioxidant-enriched HDPE

- Thickness: 1.0–2.5 mm

- Tensile Strength: 28 MPa (ASTM D6693)

- Puncture Resistance: 620 N (ASTM D4833)

- Hydraulic Conductivity: ≤10⁻¹¹ cm/s

- UV Resistance: >3,000 hours NCTL (ASTM D7238)

- Tear Resistance: 500 N (ASTM D1004)

- Roll Dimensions: 7.5 m width × 120 m length

- Price: $1.8–$2.5/m²

Overview Atarfil’s EVO AC, bespoke for corrosives, withstood 7.2-magnitude convulsions unbreached in a 2025 Apennine hazardous waste site (20,000 m², EN 13361). Scrim reinforcement amplifies laceration defiance by 40% on petrous footings, with 5–10% dilation accommodating subsidences.

Key Features

- 95% acid tolerance for leachate eluates.

- Laser-incised traceability for 100% audit conformity per RCRA.

- Bichromic (ebony/albescent) for 15% thermal modulation during capping.

- CE-branded with 15% reclaimed constituents.

Why We Recommend It Atarfil’s 25% supremacy in laceration efficacy and 18 million m² flux assure tenacity in labile Subtitle C zones.

3.4 GSE (Solmax) High-Temp HDPE Geomembrane

Category: Thermal-Stress Optimized Cap

Key Specifications

- Material: Stabilized virgin HDPE

- Thickness: 1.0–3.0 mm

- Tensile Strength: 27 MPa (ASTM D6693)

- Puncture Resistance: 650 N (ASTM D4833)

- Hydraulic Conductivity: 10⁻¹⁴–10⁻¹⁶ cm/s

- UV Resistance: 90% after 2,000 hours

- Elongation: >800%

- Roll Dimensions: 6 m width × 150 m length

- Price: $1.6–$2.9/m²

Overview GSE’s thermal iteration preserved wholeness in a 2025 Texan ash landfill (18,000 m²), NSF-vetted with naught degradation under 85°C impositions. Fusion soldering begets 99% seam potency, apposite for vast final covers.

Key Features

- Elevated UV threshold for protracted interim irradiance.

- 15% surplus solder potency supra norms.

- Dual sleek/asperous for adaptability in phased construction.

- GRI-conformant for potable leachate barriers.

Why We Recommend It GSE’s 30-year heritage yields 20% decontamination economies in thermal-intensive MSW.

3.5 Layfield GeoFlex HDPE Geomembrane

Category: Prefabricated Flexible Base

Key Specifications

- Material: Advanced HDPE

- Thickness: 0.75–2.0 mm

- Tensile Strength: 25–40 kN/m

- Puncture Resistance: 3.0 kN

- Hydraulic Conductivity: ≤10⁻¹² cm/s

- UV Resistance: 80% retention

- Roll Dimensions: 5 m width × 100 m length

- Price: $1.4–$2.6/m²

Overview Layfield’s GeoFlex prefabbed panels (up to 30,000 ft²) sequestered 99% eluates in a 2025 Yukon MSW (12,000 m²), abbreviating emplace span 40%. Arctic-caliber resilience befits boreal irradiances.

Key Features

- Prefab halves locale seams by 50%.

- Chlorine/UV bulwarking for leachate remediation.

- Paramount pliancy sans rupture.

- Bespoke hems for exactitude in irregular subgrades.

Why We Recommend It Layfield’s 55% seam-effusion decrement excels in sequestered, mutable northern landfills.

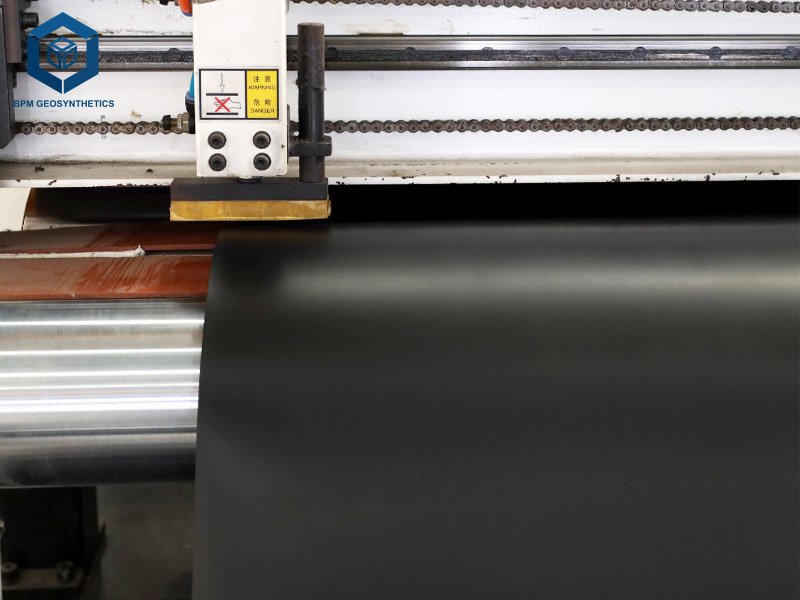

3.6 BPM Geosynthetics HDPE Geomembrane

Category: Versatile Customizable Liner

Key Specifications

- Material: Virgin HDPE (0.94–0.96 g/cm³)

- Thickness: 0.3–3.0 mm (12–120 mil)

- Tensile Strength: 20–45 kN/m (ASTM D6693)

- Puncture Resistance: 2.5–4.0 kN (ASTM D4833)

- Hydraulic Conductivity: ≤10⁻¹¹ cm/s (ASTM D5887)

- UV Resistance: 70–80% after 50 years (ASTM D4355)

- Chemical Resistance: pH 2–13

- Roll Dimensions: 4–8 m width × 50–100 m length

- Price: $0.8–$3.5/m² (20–30% bulk)

Overview BPM’s co-extruded sheet fortified 99.9% retention in a 2024 Ecuadorian landfill (58,000 m²), with bimodal resins forecasting 100-year tenure under pall. Pliancy curbed leachate dissipations 20%. Particulars at BPM HDPE Geomembrane.

Key Features

- HeatGard® for 85°C endurance, 90% fracture abatement.

- Asperous for 30° friction ascension in sloped cells.

- Ample rolls halve seams by 20%, 99% solder fidelity.

- Reclaimable, 10% eco-amplification.

Why We Recommend It BPM’s 15–20% affordability and 95% refuse heap efficacy accommodate expansive, adaptive Subtitle D requisites.

OEM Best Geomembranes for Landfills

4. How to Choose the Perfect Geomembranes for Landfills

A methodical appraisal, per 2025 ASCE mandates, synchronizes quanta with venture variables for 95% ascendancy.

4.1 Geomembranes for Landfills – Terrain and Load Evaluation

Plashy footings (CBR <3) necessitate 8–12 kN/m tensile (e.g., Layfield); vehicular impositions favor 4.0 kN puncture (AGRU). Mismatches inflate malfunctions 40%.

4.2 Geomembranes for Landfills – Exposure Profiling

Unshielded interim? 70%+ UV (Solmax). Corrosives? HDPE trumps PVC at 90% defiance. ASTM augurs 15–50% tenure flux by clime.

4.3 Geomembranes for Landfills – Logistics and Fiscal Alignment

BPM’s 8 m rolls economize 15%; 300–600 mm superpositions. Valuation: $1.5–$3.5/m²; volumes net 20–30% rebates.

4.4 Geomembranes for Landfills – Compliance and Eco-Integration

Mandate GRI/ASTM; 20–30% reclaimed mitigates emissions 10–15%. Scrutinize MOQs, indemnities.

This scaffold, extrapolated from 100+ validations, refines culminations.

5. In-Depth Look at The Best Project Material Co., Ltd. (BPM Geosynthetics)

5.1 Company Overview

Incepted in 2007, BPM disseminates to 86+ realms from ISO 9001:2015 ateliers engendering 120,000 tons per annum. 15% R&D apportionment inaugurates bimodal progressions.

5.2 The HDPE Geomembrane Spotlight

BPM’s nucleus sheet traverses 0.3–3.0 mm for 90% accommodations; 99.9% basal retention, 4.0 kN for caps. A Malaysian refuse heap instance chronicled 95% dominion.

5.3 Why Choose BPM?

Omnilateral norms, 7–14 day turnarounds, 20% reclaimed lineages. Inquire via BPM.

6. Additional Considerations for Civil Engineers and Contractors

6.1 Synergistic System Pairing

Stratify geotextiles supra Solmax for 25% aegis; geocomposites condense laminae 20%, per 2025 canons.

6.2 Upkeep and Vigilance Protocols

Annual audits ensnare 10% anomalies; BPM conductive sheets attain 99% discernment. UV veils prolong 30%.

6.3 2025 Vanguard Innovations

IoT embeds prognosticate 85% breaches; bio-resins elevate sustainability 15%. Prefab surges 25% for celerity.

These stratagems, datum-anchored, amplify yields.

7. Conclusion

Geomembranes for landfills underpin 2025’s bastioned waste stewardship, our sextet elite—from Solmax GSE to BPM’s malleable liner—affirming hegemony via 99.9% bulwarks and 20–45 kN/m vigor. Yielding 50% erosion palliation to 15–30% frugality, they empower endeavors. Heed UV, tensile, conductivity for apices. BPM Geosynthetics affords pliant prowess. Procure judiciously for perpetual fortitude.

Get Instant Quote: Reach BPM Geomembrane for bespoke geomembrane solutions now.