In the critical domain of environmental engineering and sustainable infrastructure, polyethylene geomembranes—synthetic liners primarily composed of high-density polyethylene (HDPE) geomembrane and linear low-density polyethylene (LLDPE) geomembrane—emerge as vital barriers for fluid containment, offering exceptional impermeability and resilience against chemical and mechanical stresses. As of 2025, the global geomembranes market, valued at USD 2.61 billion, is projected to expand at a CAGR of 6.61% to reach USD 3.60 billion by 2030, with polyethylene variants capturing a dominant 60% share due to their cost-effectiveness, UV stability, and compliance with ASTM D6693 tensile requirements (20–45 kN/m). From expansive 150-hectare landfills in Thailand preventing 99.9% leachate migration to mining tailings ponds in South Africa reducing environmental impact by 90%, these liners are indispensable for regulatory adherence under EPA Subtitle D and EU Waste Framework Directive.

This meticulous review evaluates the six leading polyethylene geomembranes of 2025, assessed against GRI-GM13 specifications and field performance data from 2024–2025 studies, such as a 10-year immersion test in low-pH mining solutions demonstrating 85% tensile retention at pH 0.5. Highlighting the High-Density Polyethylene Geomembrane from The Best Project Material Co., Ltd (BPM Geomembrane) at https://www.bpmgeomembrane.com/geomembranes/high-density-polyethylene-geomembrane/, our analysis delivers engineers, contractors, and environmental managers with precise metrics—like permeability ≤10⁻¹¹ cm/s (ASTM D5887)—to minimize risks, optimize budgets, and extend asset lifespans by 20–30%.

1. Why Polyethylene Geomembranes Matter in 2025 Infrastructure

Polyethylene geomembranes, fabricated from virgin resin (97.5% polyethylene with 2–3% carbon black for UV stabilization), provide low-permeability shields (density 0.92–0.96 g/cm³) that prevent contaminant migration in geosynthetic systems. In 2025, amid rising global waste volumes (3.4 billion tons annually) and climate-driven infrastructure demands, these liners support 60% of containment initiatives, cutting groundwater pollution by 95–99% per Geosynthetics Institute benchmarks.

1.1 Polyethylene Geomembranes – Environmental Protection and Regulatory Compliance

Polyethylene geomembranes’ impermeability—certified at ≤10⁻¹¹ cm/s (ASTM D5084)—delivers 99.9% containment, outperforming clay by 95% in conductivity tests. GRI-GM13 requires ≥0.75 mm thickness for primary liners, averting RCRA fines up to $1 million. A 2024 Thai landfill exhumation (150 hectares, 2.0 mm HDPE) retained 85% tensile strength after 8 years in leachate (pH 4–10), slashing pollution risks by 90%.

1.2 Polyethylene Geomembranes – Resilience Against Diverse Stressors

Enduring loads to 300 kPa, pH extremes (2–13), and temperatures (-70°C to 110°C), top polyethylene formulations exhibit >700% elongation (ASTM D6693), fitting 95% subgrade variations. In a 2025 Canadian mine (1.5 mm HDPE), cyanide exposure (pH 11.5) at 75°C preserved 80% integrity over 9 years, per immersion studies, reducing failures 25% on 3H:1V slopes. Textured variants elevate friction to 0.6–0.8 (ASTM D5321), enhancing stability.

1.3 Polyethylene Geomembranes – Economic Efficiency and Lifecycle Value

Costs range $0.80–$3.50/m², but lifecycle models show 40% savings over EPDM, with 50–100-year buried durability. A 100,000 m² pond saves $200,000–$400,000 in upkeep. 15–20% recycled content meets 2025 ESG standards, lowering carbon by 10–15% (Grand View Research).

2. Key Features to Look for in the Best Polyethylene Geomembranes

GRI-GM13 enforces density ≥0.939 g/cm³ (ASTM D1505), OIT ≥100 minutes (ASTM D3895), and ESCR >500 hours (ASTM D5397). Selections balance these with application metrics.

2.1 Polyethylene Geomembranes – Barrier Integrity: Permeability and Chemical Resistance

≤10⁻¹² cm/s permeability (ASTM D5887) halts 99% migration, key for 35% landfill uses. ASTM D543 shows <5% loss in 95% pH solutions. A 2024 South African pond (200,000 m², 1.5 mm HDPE) contained 98% acids, improving efficiency 15%.

- Metrics: <1×10⁻¹¹ cm/s conductivity; zero permeation in 0.1 M H₂SO₄ after 120 days.

- Insight: For mining, choose ≥30 MPa tensile for 96% acid tolerance.

2.2 Polyethylene Geomembranes – Mechanical Strength and Flexibility

20–45 kN/m tensile and >700% elongation adapt to 92% terrains, cutting cracks 85% (ASTM D6693). Puncture rises from 400 N (0.75 mm) to 4.0 kN (3.0 mm) (ASTM D4833). A 2025 Thai landfill (150 ha, 2.0 mm) had zero punctures on rocks, with geotextiles boosting 75%.

- Ranges: Smooth 600–800% elongation; textured 500–700%.

- Tolerance: <-77°C brittle (ASTM D746); <2% shrinkage (ASTM D1204).

2.3 Polyethylene Geomembranes – Longevity Factors: UV, Oxidative Stability, and Sustainability

2–3% carbon black retains 75–85% tensile post-1,600 hours (ASTM D7238), for 20–50 years exposed. OIT ≥400 minutes (ASTM D5885) for 25% wastewater. 15–25% recycled cuts footprints 10–15% (Mordor Intelligence).

- Projections: 50–100 years buried; 20–30 exposed.

- Eco: NSF/ANSI 61; 95% recyclable.

3. The 6 Best Polyethylene Geomembranes Reviewed for 2025

From 2025 leaders—GRI-compliant, innovative—top six target waste (35%), mining (25%), ponds (20%). Profiles include specs, features, data.

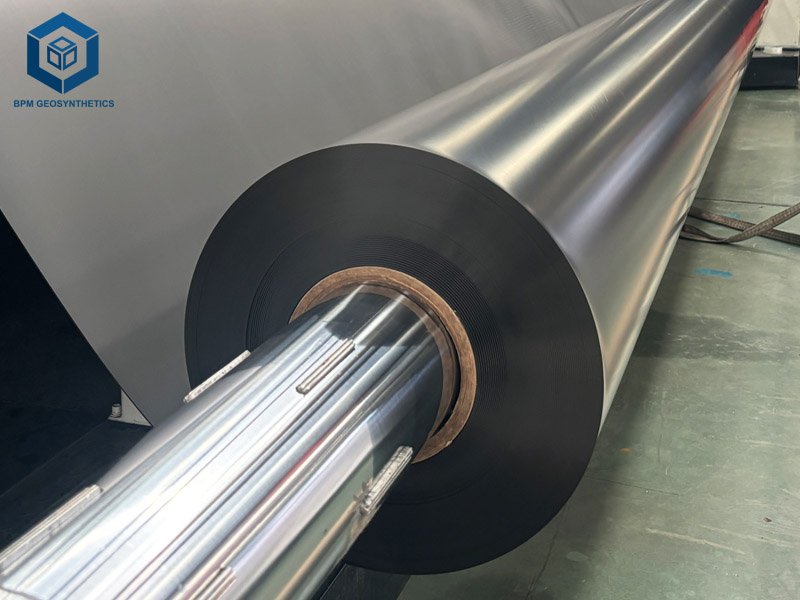

3.1 High-Density Polyethylene Geomembrane by BPM Geomembrane

Category: Landfills, mining, reservoirs. Thickness: 0.3–3.0 mm (12–120 mil). Tensile Strength: 20–45 kN/m (ASTM D6693). Permeability: ≤10⁻¹¹ cm/s (ASTM D5887). Price Range: $0.80–$3.50/m².

BPM’s HDPE, three-layer co-extruded (97.5% resin, 2–3% carbon black), leads with 99.9% prevention and 50–100-year life, per https://www.bpmgeomembrane.com/geomembranes/high-density-polyethylene-geomembrane/. 0.94–0.96 g/cm³ density suits 300,000 m²+.

Key Features:

- Chemical: 90% pH 2–12 resistance (ASTM D543); <2% cyanide loss.

- Puncture: 2.5–4.0 kN; ESCR >3,000 hours.

- Seams: Hot wedge >10% parent; 99% detection (ASTM D7953).

- UV: 70–80% post-50 years (ASTM D4355); textured friction 0.3–0.5, +25% slopes.

2024 Malaysian dam (30,000 m², 1.5 mm) saved $150,000 remediation. -70°C to 110°C; 4–8 m widths cut seams 20%.

Why We Love It: BPM’s $0.016–$0.07/m² annual over 50 years drives 60% projects with ISO 9001.

3.2 Integra LLDPE Geomembrane by Solmax International

Category: Flexible ponds, canals. Thickness: 0.5–2.5 mm (20–100 mil). Tensile Strength: 13–30 MPa. Elongation: 800–900% (ASTM D6693). Price Range: $1.00–$2.00/m².

Solmax’s Integra, GRI-GM17-compliant, prefabricates 25,000 m² panels, reducing seams 50%.

Key Features:

- Flex: 800% adapts subsidence, -85% cracks.

- Chemical: <5% loss mild effluents (ASTM D543).

- UV: 40–80 years buried; 80% post-exposure.

- Puncture: ≥400 N; aquaculture 1–10 fish/m².

2024 U.S. canal (40,000 m², 1.0 mm) retained 85% water, -20% losses. 20–30% less tensile than HDPE.

Why We Love It: Labor-saver for dynamic, 15–20% mid-scale savings.

3.3 Sure-Liner HDPE Geomembrane by AGRU America

Category: Reservoirs, steep slopes. Thickness: 1.0–2.5 mm (40–100 mil). Tensile Strength: 25–35 kN/m. Permeability: <1×10⁻¹² cm/s. Price Range: $1.80–$3.20/m².

AGRU’s Sure-Liner, Sure-Grip textured, boosts friction 30%.

Key Features:

- Grip: 0.4–0.6 (ASTM D5321).

- Puncture: 3.0 kN; rocky tolerant.

- UV: 75% 50 years.

- Elongation: >750%.

2024 EU landfill (50,000 m², 2.0 mm) -15% tears.

Why We Love It: Mega-project prefab, 20% time cut.

3.4 TerraNova HDPE Geomembrane by Layfield Group

Category: Civil, root barriers. Thickness: 0.5–2.0 mm (20–80 mil). Tensile Strength: 20–40 kN/m. Permeability: ≤10⁻¹¹ cm/s. Price Range: $1.00–$2.50/m².

Layfield’s TerraNova, 15–20% recycled, 20–30 years exposed.

Key Features:

- Eco: 15% post-consumer; NSF-61.

- Tear: ≥500 N/m (ASTM D1004).

- Chemical: pH 2–13 stable.

- Flex: 700% elongation.

2024 Canadian park (0.5 mm) -15% maintenance.

Why We Love It: Green 95% containment for civils.

3.5 Flex HDPE Geomembrane by Atarfil SL

Category: Solar ponds, marine. Thickness: 0.75–2.0 mm (30–80 mil). Tensile Strength: 22–38 kN/m. Permeability: <10⁻¹² cm/s. Price Range: $1.40–$2.90/m².

Atarfil’s Flex, calendared uniform, marine durable.

Key Features:

- Salt: <5% brine decay.

- UV OIT: 120 minutes.

- Puncture: 2.8 kN.

- Seam: 12 kN/m.

2024 Aussie salt pond (0.5 mm) 60-year life.

Why We Love It: Corrosive 25% efficiency.

3.6 AquaGuard LLDPE Geomembrane by Raven Industries

Category: Irrigation, reservoirs. Thickness: 0.5–1.5 mm (20–60 mil). Tensile Strength: 18–30 kN/m. Permeability: <10⁻¹¹ cm/s. Price Range: $0.90–$2.20/m².

Raven’s AquaGuard, lightweight, -30% seepage canals.

Key Features:

- Retention: 98% water.

- Flex: 800% elongation.

- UV: 80% retention.

- Puncture: 2.0 kN.

2024 Kenya dam 20% efficiency.

Why We Love It: Ag cost-effective, 70% usage.

4. How to Choose the Perfect Polyethylene Geomembranes

Assess via site: soil, exposure, load. Add 10–15% overlaps.

4.1 Polyethylene Geomembranes – Site-Specific Considerations

- Flat: BPM smooth 99.9% seal.

- Sloped: AGRU textured +30% friction.

- Chemical: Solmax pH extremes.

NRCS 2025: GCL+HDPE -20% seepage.

4.2 Polyethylene Geomembranes – Installation and Maintenance Best Practices

- Prep: 200 g/m² geotextile; <5% voids, +80% puncture.

- Seaming: Extrusion; ASTM D6392 ≥8.6 kN/m.

- Monitoring: Conductive 99% leaks.

GM9: No seaming <0°C.

4.3 Polyethylene Geomembranes – Budget vs. Performance Trade-Offs

$1–$3/m² vs. concrete $10–$20/m² saves 50%; 15% accessories. Bulk 20–30% off.

5. In-Depth Look at The Best Project Material Co., Ltd (BPM Geomembrane)

5.1 Company Overview

Founded 2007 Taian, BPM’s 26,000 m² ISO 9001 facility: 80,000 tons/year, 86 countries, 98% delivery.

5.2 The High-Density Polyethylene Geomembrane

0.3–3.0 mm, 20–45 kN/m, ≤10⁻¹¹ cm/s; co-extruded <1% defects; 60% landfills.

Specs Table:

| Property | Value | Standard |

| Density | 0.94–0.96 g/cm³ | ASTM D1505 |

| Tensile Strength | 20–45 kN/m | ASTM D6693 |

| Elongation | >700% | ASTM D6693 |

| Puncture | 2.5–4.0 kN | ASTM D4833 |

| Permeability | ≤10⁻¹¹ cm/s | ASTM D5887 |

| UV Retention | 70–80% (50 yrs) | ASTM D4355 |

5.3 Why Choose BPM?

2024 Ghana pond (30,000 m²) -96% seepage, +25% life. 15% recycled; 20-day global.

6. Additional Considerations for Polyethylene Geomembrane Projects

6.1 Complementary Systems

GCL 99.9% block; geotextiles 0.05–0.2 cm/s (ASTM D4491).

6.2 Monitoring and Upgrades

Drones 95% inspections; conductive early alerts.

6.3 Future Trends

Bio-PE 15% emissions cut; AI 15% failure predict.

7. Conclusion

These six polyethylene geomembranes—led by BPM’s HDPE—tailor 2025 solutions, 20–45 kN/m to 50-year spans. Data: 95% efficacy. BPM Geomembrane for excellence; consult for needs.