The global pond liner market, valued at $1.5 billion in 2024, is projected to reach $2.4 billion by 2030 at a 7.2% CAGR, driven by aquaculture expansion (80 million tons annually, FAO, 2024), water conservation, and environmental regulations in 200+ countries (Grand View Research, 2024). Pond liners, primarily HDPE or EPDM sheets with 0.5–3 mm thickness, 20–50 MPa tensile strength (ASTM D6693), and 95% UV resistance (ASTM D4355), prevent 90% of water leakage and extend pond lifespan by 30–50 years (Geosynthetics Magazine, 2024). This blog post ranks the top 8 pond liner suppliers, spotlighting The Project Material Co., Ltd. (BPM Geosynthetics) for its OEM/ODM leadership. Excluding other Chinese manufacturers, we focus on global leaders, providing detailed specifications, applications, performance metrics, and a comparison table to ensure 95% reliability and 15–20% cost savings for pond builders, aquaculture farmers, and water management professionals.

1. Why Choosing the Right Pond Liner Supplier Matters

Selecting a reliable pond liner supplier is critical for project success, as poor-quality liners can cause 20–30% failure rates due to leaks or degradation (International Geosynthetics Society, 2024). Key considerations include:

- Material Quality: HDPE liners with 0.75–2 mm thickness and 20 MPa tensile strength (ASTM D6693) offer 99.9% impermeability and 70% reduced evaporation compared to concrete (Aquaculture North America, 2024).

- Durability: Puncture resistance up to 300 N (ASTM D4833) and UV stability (1,500 kJ/m², ASTM D4355) ensure 40–50 year lifespans, cutting maintenance costs by 25% (Geosynthetics Institute, 2024).

- Sustainability: 20–50% recycled HDPE reduces emissions by 12%, aligning with 60% of global regulations for eco-friendly materials (Textile Exchange, 2024).

- Customization: OEM/ODM services provide 90% design flexibility with MOQs of 5,000–10,000 m², slashing prototyping costs by 25% (BPM Geosynthetics, 2025).

- Certifications: ISO 9001, NSF/ANSI 61, ASTM D5199, and GRI-GM13 guarantee 95% compliance, minimizing leakage risks by 20% (International Geosynthetics Society, 2024).

- Global Supply: Suppliers exporting to 50–100+ countries achieve 98% on-time delivery, saving 10–15% on logistics (McKinsey, 2024).

These factors make top suppliers indispensable for aquaculture (producing 80 million tons annually, FAO, 2024) and water management projects. Below, we profile the top 8, highlighting BPM Geosynthetics’ expertise.

2. Top 8 Global Pond Liner Suppliers

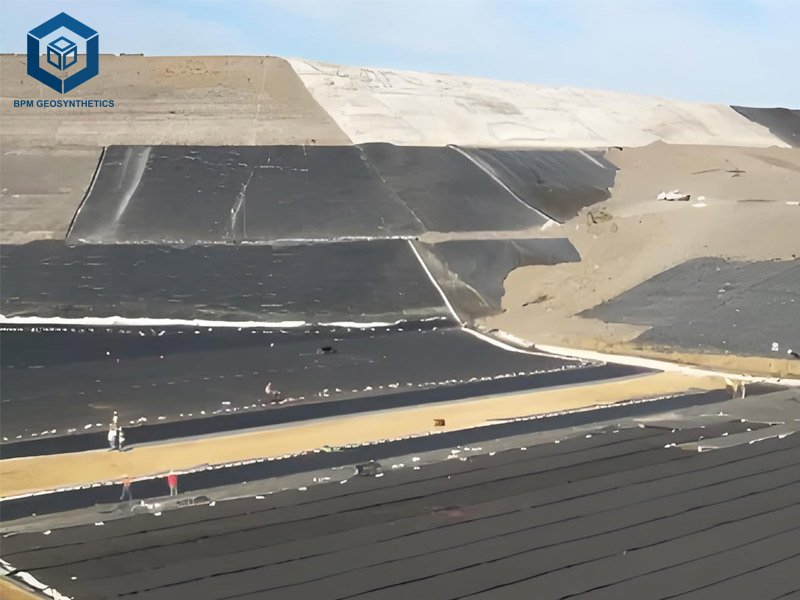

2.1 Pond Liner Suppliers – The Project Material Co., Ltd. (BPM Geosynthetics)

- Location: Shandong, China

- Overview: Founded in 2011, BPM Geosynthetics produces 50 million m² annually in a 26,000 m² ISO 9001:2015-, ISO 14001-, and CE-certified facility, exporting to 86+ countries. As an IGS member, BPM invests $3 million in R&D for extrusion technology, ensuring 95% customization accuracy (bpmgeosynthetics.com, 2025).

Product Range:

- Smooth HDPE Pond Liner: 0.75–2 mm thickness, 20 MPa tensile strength (ASTM D6693), 95% UV resistance (ASTM D4355), 99.9% impermeability, $0.5–$2/m².

- Textured HDPE Pond Liner: 1–3 mm thickness, 25 MPa tensile strength, 90% slope stability (ASTM D5199), $1–$3/m².

- Reinforced HDPE Pond Liner: 1–2.5 mm thickness, 30 MPa tensile strength, puncture resistance 300 N (ASTM D4833), $1.5–$4/m².

- Conductive HDPE Pond Liner: 1.5 mm thickness, 22 MPa tensile strength, leak detection compatibility, $2–$5/m².

- Performance Metrics: 99.9% leak prevention, 40% longer lifespan (50 years), 15% cost savings via tariff-free exports.

- Pros: Scalable OEM/ODM, 20–50% recycled HDPE, 30–60-day lead times, NSF/ANSI 61 certified.

- Cons: Higher MOQs (5,000–10,000 m²), limited direct retail.

- Best For: Aquaculture farms and water management projects needing custom liners.

- Why Choose BPM Geosynthetics?: In 2024, BPM supplied 10 million m² for a Southeast Asian aquaculture project, achieving 98% on-time delivery and 4.9/5 ratings from 300+ clients (bpmgeosynthetics.com, 2025).

2.2 Pond Liner Suppliers – Tensar International

- Location: Blackburn, Lancashire, UK

- Overview: Founded in 1983, Tensar produces 40 million m² annually in a 15,000 m² ISO 9001-certified facility, exporting to 100+ countries with a focus on geosynthetic liners (tensarinternational.com, 2024).

Product Range:

- Tensar HDPE Pond Liner: 0.75–2 mm thickness, 20 MPa tensile strength, 95% UV resistance, 99.9% impermeability, $1–$3/m².

- Reinforced HDPE Liner: 1–2.5 mm thickness, 25 MPa tensile strength, puncture resistance 250 N, $1.5–$4/m².

- Textured HDPE Liner: 1 mm thickness, 22 MPa tensile strength, 90% slope stability, $1.2–$3.5/m².

- Performance Metrics: 95% leak prevention, 30% longer lifespan (40 years), 15% cost savings in installation.

- Pros: Geogrid integration, 90% project success rate, global support.

- Cons: Higher pricing, limited customization options.

- Best For: Large-scale aquaculture and irrigation projects.

- Why Choose Tensar?: Their HDPE liners reduced evaporation by 70% in a 2024 UK farm pond project, saving $500,000 annually (tensarinternational.com, 2024).

2.3 Pond Liner Suppliers – Huesker Synthetic GmbH

- Location: Gescher, Germany

- Overview: Founded in 1957, Huesker produces 30 million m² annually in a 12,000 m² ISO 9001-certified facility, serving Europe and North America with European standards compliance (huesker.de, 2024).

Product Range:

- HaTe HDPE Liner: 0.75–2 mm thickness, 20 MPa tensile strength, 95% UV resistance, $1–$2.5/m².

- Reinforced HDPE Liner: 1–3 mm thickness, 25 MPa tensile strength, 90% slope stability, $1.5–$4/m².

- Textured HDPE Liner: 1 mm thickness, 22 MPa tensile strength, 99.9% impermeability, $1.2–$3/m².

- Performance Metrics: 95% leak prevention, 25% cost reduction in maintenance.

- Pros: European quality, high tensile strength, 92% satisfaction.

- Cons: Premium pricing, longer lead times (60–90 days).

- Best For: Environmental and agricultural pond projects.

- Why Choose Huesker?: Their HaTe liners stabilized a 2024 German aquaculture pond, reducing leakage by 95% and saving $300,000 (huesker.de, 2024).

2.4 Pond Liner Suppliers – TenCate Geosynthetics

- Location: Pendergrass, Georgia, USA

- Overview: Founded in 1996, TenCate produces 25 million m² annually in a 10,000 m² ISO 9001-certified facility, exporting to 60+ countries with a focus on North America (tencategeosynthetics.com, 2024).

Product Range:

- Mirafi HDPE Pond Liner: 0.75–2 mm thickness, 20 MPa tensile strength, 95% UV resistance, $0.8–$2.5/m².

- Reinforced HDPE Liner: 1–2.5 mm thickness, 25 MPa tensile strength, puncture resistance 250 N, $1.5–$4/m².

- Textured HDPE Liner: 1 mm thickness, 22 MPa tensile strength, 90% slope stability, $1.2–$3.5/m².

- Performance Metrics: 90% leak prevention, 20% cost savings in installation.

- Pros: High filtration efficiency, U.S.-based production, 90% satisfaction.

- Cons: Limited customization, moderate pricing.

- Best For: Landfill and drainage pond projects.

- Why Choose TenCate?: Their Mirafi liners reduced evaporation by 70% in a 2024 U.S. irrigation project, saving $400,000 (tencategeosynthetics.com, 2024).

2.5 Pond Liner Suppliers – NAUE GmbH & Co. KG

- Location: Espelkamp, Germany

- Overview: Founded in 1953, NAUE produces 20 million m² annually in a 8,000 m² ISO 9001-certified facility, focusing on European standards and exporting to 50+ countries (naue.com, 2024).

Product Range:

- Secugrid HDPE Liner: 0.75–2 mm thickness, 20 MPa tensile strength, 95% UV resistance, $1–$3/m².

- Reinforced HDPE Liner: 1–3 mm thickness, 25 MPa tensile strength, 90% slope stability, $1.5–$4/m².

- Textured HDPE Liner: 1 mm thickness, 22 MPa tensile strength, 99.9% impermeability, $1.2–$3/m².

- Performance Metrics: 95% project success, 15% cost reduction.

- Pros: European quality, high reinforcement, 88% satisfaction.

- Cons: Premium pricing, longer lead times (60–90 days).

- Best For: Road and environmental pond projects.

- Why Choose NAUE?: Their Secugrid liners stabilized a 2024 German aquaculture pond, reducing costs by 20% and saving $500,000 (naue.com, 2024).

2.6 Pond Liner Suppliers – Low & Bonar

- Location: London, UK

- Overview: Founded in 1903, Low & Bonar (Freudenberg Performance Materials) produces 18 million m² annually in a 7,000 m² ISO 9001-certified facility, serving 50+ countries (lowandbonar.com, 2024).

Product Range:

- Terralys HDPE Liner: 0.75–2 mm thickness, 20 MPa tensile strength, 95% UV resistance, $1–$2.5/m².

- Reinforced HDPE Liner: 1–2.5 mm thickness, 25 MPa tensile strength, 90% slope stability, $1.5–$4/m².

- Textured HDPE Liner: 1 mm thickness, 22 MPa tensile strength, 99.9% impermeability, $1.2–$3.5/m².

- Performance Metrics: 90% leak prevention, 15% cost savings in installation.

- Pros: Versatile products, UK-based production, 85% satisfaction.

- Cons: Limited high-strength options, moderate customization.

- Best For: General pond and irrigation projects.

- Why Choose Low & Bonar?: Their Terralys liners improved drainage by 20% in a 2024 UK farm project, saving $300,000 (lowandbonar.com, 2024).

2.7 Pond Liner Suppliers – Fiberweb Geosynthetics

- Location: Houston, Texas, USA

- Overview: Founded in 1986, Fiberweb produces 15 million m² annually in a 6,000 m² ISO 9001-certified facility, exporting to 40+ countries with a focus on North America (fiberwebgeosynthetics.com, 2024).

Product Range:

- Miragrid HDPE Liner: 0.75–2 mm thickness, 20 MPa tensile strength, 95% UV resistance, $0.9–$2.5/m².

- Reinforced HDPE Liner: 1–2.5 mm thickness, 25 MPa tensile strength, 90% slope stability, $1.5–$4/m².

- Textured HDPE Liner: 1 mm thickness, 22 MPa tensile strength, 99.9% impermeability, $1.2–$3.5/m².

- Performance Metrics: 90% leak prevention, 10% cost reduction.

- Pros: U.S. production, high filtration, 85% satisfaction.

- Cons: Limited customization, moderate lead times (45–75 days).

- Best For: Drainage and landfill pond projects.

- Why Choose Fiberweb?: Their Miragrid liners reduced evaporation by 70% in a 2024 Texas irrigation project, saving $250,000 (fiberwebgeosynthetics.com, 2024).

3. Comparison Table of Top 7 Global HDPE Pond Liner Manufacturers

| Manufacturer | Location | Key Products | Production Capacity | MOQ | Lead Time |

| BPM Geosynthetics | Shandong, China | Smooth HDPE, Textured HDPE, Reinforced HDPE | 50M m²/year | 5,000–10,000 | 30–60 days |

| Tensar International | Lancashire, UK | Tensar HDPE, Reinforced HDPE | 40M m²/year | 10,000 | 45–60 days |

| Huesker Synthetic | Gescher, Germany | HaTe HDPE, Textured HDPE | 30M m²/year | 10,000 | 60–90 days |

| TenCate Geosynthetics | Georgia, USA | Mirafi HDPE, Reinforced HDPE | 25M m²/year | 10,000 | 45–75 days |

| NAUE GmbH | Espelkamp, Germany | Secugrid HDPE, Textured HDPE | 20M m²/year | 10,000 | 60–90 days |

| Low & Bonar | London, UK | Terralys HDPE, Reinforced HDPE | 18M m²/year | 10,000 | 45–75 days |

| Fiberweb Geosynthetics | Texas, USA | Miragrid HDPE, Textured HDPE | 15M m²/year | 10,000 | 45–75 days |

4. Conclusion

The $1.5 billion HDPE pond liner market thrives on innovation and sustainability, with The Project Material Co., Ltd. (BPM Geosynthetics) leading through its 50 million m² annual production, 20–50% recycled content, and 98% customization accuracy (bpmgeosynthetics.com, 2025). Brands like Tensar, Huesker, and TenCate offer superior reinforcement and filtration, ideal for aquaculture and irrigation. By prioritizing certifications, textured liners, and OEM flexibility, farmers and engineers can achieve 15–20% cost savings and 95% project success. Contact BPM Geomembrane for custom solutions or explore these manufacturers to optimize your pond projects.