To avoid establishing failed partnerships, this article will focus on ten Indonesian Geomembane Pond Liner manufacturers and factories that offer excellent design, high-quality materials, and commitment to sustainable and ethical manufacturing practices.

1 Top 10 Geomembane Pond Liner Manufacturer Indonesia

1.1 SOLMAX

Soma Group was established in Quebec, Canada in 1981 and established a factory in Malaysia in 2009 to produce HDPE/LLDPE geomembranes. In 2017, a company was established in Houston, USA to enter the waste management business in the oil and gas extraction field. At the end of 2017, Soma Group acquired the geosynthetic material brand GSE. In 2018, Solmax became Solmax GSE, and in 2019, the group announced that it would be known as Solmax in all the territories in which it operates. In 2021, Somma Group once again teamed up with the globally renowned geosynthetic material manufacturer, the Royal Dutch Ten Cate Group (Fiber Science), to further strengthen its market position in the geosynthetic materials field.

SOLMAX, a Canadian conglomerate, has factories in North America, Europe, the Middle East, Africa, and Asia (Malaysia, Thailand, Suzhou, China) with an annual production capacity of 250000 tons. A global production supply chain system can provide customers with higher quality, faster, and more effective after-sales service guarantees.

The series of geomembranes produced by Soma include standard HDPE geomembrane series (meeting or exceeding the GRI-GM13 standard), standard LLDPE geomembrane series (meeting or exceeding the GRI-GM17 standard), and colored geomembrane series (black, white, green, brown, etc.). High performance geosynthetic film series, conductive geosynthetic film series, high-temperature resistant geosynthetic film series, concrete nail embedded film series, flexible vertical anti-seepage system, concrete connection lock, and extruded welding rod series that far exceed the GRI-GM13 and GRI-GM17 standards.

1.2 NAUE

Germany’s NAUE Fiber Technology Company was established in 1984. In 1993, NAUE Anti Seepage Engineering Company entered the field of landfill construction. In 1996, it acquired the geomembrane business from a tunnel engineering company under the brand Carbofol ®。 In 2000, NAUE used a flat extrusion process to produce the widest geotextile film in the world at that time, with a width of 9.40 meters. In 2017, NAUE started production at a new factory in Fester, producing Carbofol ® Geomembrane.

Carbofol ® Made of high-quality polyethylene resin with a width of 7.50m. For the rough facial mask used for slope seepage prevention, Carbofol ® The use of embossing technology in production can significantly improve the interaction effect.

Carbofol ® There are white edge markings on both sides of the geomembrane, which are recommended overlapping areas and serve as visual aids during installation. In addition, two edges are covered with thin protective sheets (150mm wide), which are immediately peeled off before welding to keep the welding area absolutely clean. Carbofol ® The melt index (MFR) of HDPE geomembrane tested at 190 ° C/5kg ranges from 1 to 3g/10 minutes, with a wide welding construction window.

1.3 MACCAFERRI

MACCAFERRI, headquartered in Italy, has a history of over 140 years. As a global company, Markfield has over 70 subsidiaries worldwide, offices in over 100 countries, and over 3000 employees.

MACCAFERRI is not simply selling products, but strives to provide leading technical solutions for designing and advancing challenging projects. The company is firmly committed to providing better technical and engineering solutions through focus, communication, innovation, and collaboration.

MACCAFERRI provides different types of geotechnical materials, and as early as the 19th century, MACCAFERRI invented Gabion (gabion mesh). MACCAFERRI produces geomembranes under the brand MacLine ®。 MacLine ® SDH is a dual gloss HDPE geomembrane; MacLine ® MH&RDH is a high-density rough geomembrane, with Macline RDH being double rough and RMH being single rough, and its performance is similar to that of standard smooth products. In addition, MacLine ® W is HDPE reinforced geotextile film, with high-density polyethylene filament woven geotextile as the core layer, and polyethylene film covering both upper and lower sides, which has extremely high mechanical strength.

1.4 HUITEX

HUITEX is located in Tainan, Taiwan and has established a reliable reputation since the 1990s by providing stable and consistent quality products to global customers. HUITEX is a member of the International Geosynthetic Society (IGS) and the International Association of Geosynthetic Installers (IAGI).

HUITEX has passed ISO 9001 and 14001 certifications and has three blown film production lines, producing HDPE/LLDPE smooth and rough geomembranes. High quality geomembranes, geochambers, and concrete protective pads can be manufactured for major geotechnical applications such as landfills, wastewater treatment, tunnels, waterproofing, mining engineering, and slope protection. Among them, HUITEX reinforced HDPE geomembranes are specifically developed for harsh application environments, aiming to separate polluted wastewater such as coalbed methane wastewater from surrounding rural areas and bottom aquifers.

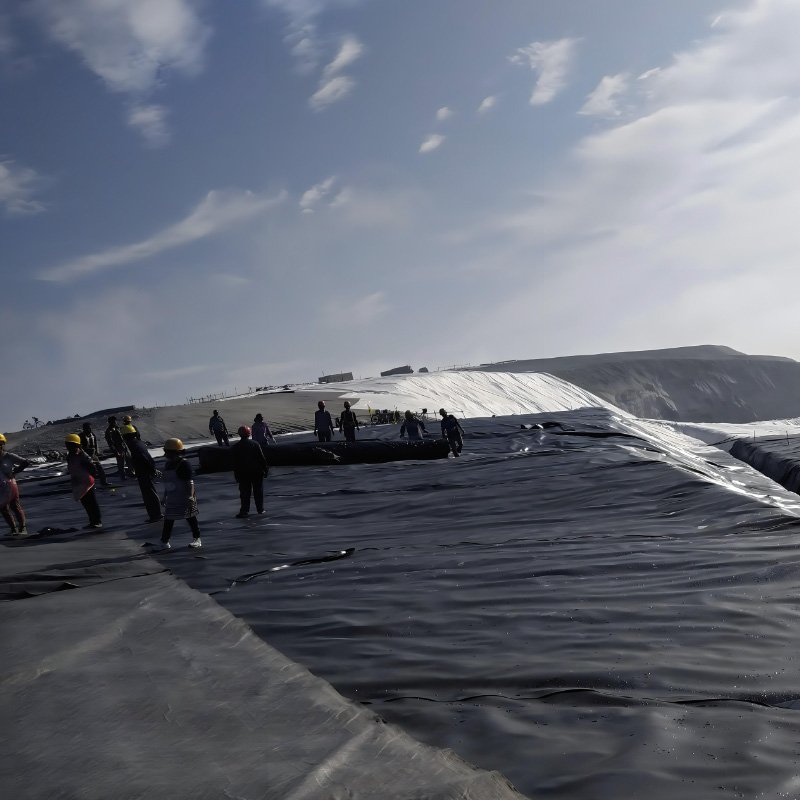

1.5 BPM Geosynthetics

As the professional geomembrane manufacturers and suppliers, BPM Geomembrane has dedicated to supplying one stop geosynthetic products and services to worldwide customers since its foundation in 2007. We have over 150 professional staffs and 26,000 square meters manufacturing factory equipped with automatic production lines. Our innovative, high quality geosynthetic products include geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids, etc. All BPM geosynthetics has been certificated by the ISO9001, ISO14001, Soncap, SASO and BV certificates and passed the test of SGS and Intertek etc. Product innovation, quality assurance and customer satisfaction are our long term commitment to our worldwide customers.

1.6 AKS

AKS anti-seepage system company located in Cape Town, South Africa uses the flat extrusion and rolling process to produce HDPE/LLDPE geomembranes under the brand Geoliner ®, Width of 7m, thickness of 1-3mm, and customizable according to project requirements, while also considering installation requirements, roll length, truck and container loading configurations. In order to facilitate product identification, tracking, and traceability, all products have separate coded labels; In the production process of geosynthetic membranes, each roll is labeled with a roll number and length scale for easy on-site construction.

Geoliner ® Geomembranes can be smooth, rough, or super rough, and can be single or double rough. AKS company has obtained ISO 9001:2015 certification and follows strict codes of conduct to ensure product quality. The well-equipped laboratory ensures that all geomembranes produced comply with international standards such as GRI-GM13 (HDPE) and GRI-GM17 (LLDPE), as well as the requirements of the South African industry standard SANS 1526.

1.7 TDM

TDM Company was founded in 1992, and its geomembrane products include the widely used HDPE and LLDPE series for the control of liquid or solid waste. TDM’s HDPE/LLDPE geomembrane is made of high-quality specialized polyethylene resin, which has excellent resistance to chemical corrosion and biodegradation, as well as strong UV resistance.

TDM provides complete solutions for mining heap leaching sites, tailings dams, municipal and industrial solid waste landfills, reservoirs and canals, tunnels, chemical waste pools, landscape lakes and swimming pools, as well as buildings, including the installation and construction of geosynthetic materials. Its vision is to provide comprehensive solutions based on strict technology, high-performance products, and professional and high-quality installation services for the engineering and construction markets.

1.8 GEOSINCERE

Shandong GEOSINO New Material Co.,Ltd (Brand: GEOSINCERE) has more than 200 employees, including 78 professional and technical personnel with senior and intermediate professional titles. They have German KARL MAYER high-speed “Raschel” warp knitting machines, MALIM0 multi axial looms, and DONEIL looms, as well as two bidirectional grille production lines and two unidirectional grille production lines, and have mastered Menzel’s coating technology. We mainly produce and operate various engineering materials such as glass fiber, polyester geogrid, unidirectional plastic geogrid, bidirectional plastic geogrid, new three-dimensional geogrid mat, high-strength geogrid, geogrid chamber, engineering fiber, geotextile, composite geomembrane, warp knitted composite geogrid, glass fiber short cut felt, glass fiber composite felt, etc.

1.9TMP

TMP® GEOSYNTHETICS, established in 1998, has specialized in the production and marketing of geogrids, geotextiles, geocells, and engineering fibers. The company now has a staff of 200 and 18 sets of professional high-tech equipment for geosynthetics production. On 2017, TMP America started its first geogrid production line in the U.S, marking the first step onto the U.S.

TMP takes integrity and innovation as its core development philosophy. With 24 years of experience, TMP has become one of the world’s leading geosynthetics manufacturers and has built its reputation on a commitment to provide high-quality products and efficient services for its global clients.

1.10 SKAPS Industries

SKAPS Industries uses extrusion technology to produce various geosynthetic materials and industrial fabrics, which are widely used in civil, environmental, or industrial engineering, and have strong market influence in more than 60 countries.

SKAPS Industries’ factory in Georgia, USA utilizes two state-of-the-art production lines and the latest “blow film” process to achieve customized production of high-quality HDPE and LLDPE geomembranes. The thickness is 0.75mm~3.0mm, with smooth, single rough or double rough surfaces on the surface; The colors can be black, gray, and white, and there are conductive geomembranes and ordinary geomembranes available. The roughness height can be adjusted according to design requirements to meet strict anti friction requirements. The standard width is 7m, and the customized width can reach 8m, making it the widest rough geomembrane in North America at that time.

2. How to Find Geomembane Pond Liner Manufacturer Indonesia

Here are some of the best ways to find Indonesian Geomembane Pond Liner manufacturers for your business:

Online research: Search engines and directories such as Google, Alibaba, Thomas, or Makers Row can list available Geomembane Pond Liner manufacturers.

Trade shows: Participating in trade shows for specific industries, such as Texworld USA or MAGIC, can help you find various Geomembrane Pond Liner Manufacturers one roof.

Local directory: You can check the local business directory to find the Geomembane Pond Liner manufacturer in your region.

Recommendation: Seeking recommendations from industry associations or other fashion companies is a good way to find Geommembane Pond Liner manufacturers.

Social media: Use social media platforms to seek recommendations or search for Geoembane Pond Liner Manufacturers. Some top platforms include Instagram, Facebook, and LinkedIn.

3. Things to Consider When Choosing a Geomembane Pond Liner Manufacturer

Before collaborating with any manufacturer, you must evaluate several factors to avoid misunderstandings. The following are several factors to consider when choosing a manufacturer of Geomembane Pond Liner :

Production capacity: Ensure that your preferred manufacturer can produce the products you want. In addition, check if they have the necessary equipment and professional knowledge to complete the task.

Quality standards: Check if the manufacturer’s standards and certifications meet your requirements.

Pricing: Inquire for detailed pricing information, including minimum order quantity and additional costs, to ensure that you can afford the manufacturer’s fees.

Delivery cycle: Consider the manufacturer’s delivery cycle to see if they can meet your delivery schedule.

Communication: A responsive and skilled manufacturer will regularly update your order progress without keeping you in the dark.

Sustainability: Check the manufacturer’s sustainability practices and certifications to ensure they align with your brand values.

Reputation: Study the manufacturer’s reputation to ensure reliability and credibility.

4. How To Negotiate Prices and Terms With Pond Liner Manufacturers?

Here are some tips for negotiating prices and terms with Geomembane Pond Liner manufacturers:

Survey: Conduct a survey on the market prices of products. These pieces of information will make your negotiations easier.

Establishing Relationships: Balancing friendly and professional relationships with manufacturers, and building positive relationships.

Clear communication: Always clearly and concisely state your requirements, including minimum order quantity, pricing, and other additional costs.

Negotiate bulk discounts: Do you plan to place a large order? Ensure negotiating bulk discounts to reduce overall costs.

Be flexible: Don’t be rigid! Willing to make compromises to reach a common agreement.

Record everything: Ensure that you correctly record all terms, including pricing and delivery schedules.

Don’t be sentimental: If negotiations fail or the manufacturer doesn’t meet your requirements, be prepared to leave.

5. Conclusion

Finding the best manufacturer of geotextile pond liners requires careful study and evaluation of multiple factors. By spending time carefully studying potential manufacturers and thoroughly negotiating terms, brands can establish long-term relationships with reliable partners to help produce high-quality products that meet customer needs.

Fortunately, our carefully planned list of ten outstanding geosynthetic pond liner manufacturers will help simplify your research and make collaboration with perfect manufacturers easier and faster.