High-Density Polyethylene (HDPE) geomembranes are critical in environmental and civil engineering projects, providing impermeable barriers for applications like landfill liners, water containment, and mining operations. With the global geomembrane market projected to reach $3.5 billion by 2027, growing at a CAGR of 5.2% from 2020, HDPE geomembranes account for 35% of the market due to their durability and chemical resistance. Selecting a reliable manufacturer is essential for ensuring project integrity, as quality, customization, and compliance with international standards directly impact performance. This article explores the top 7 global HDPE geomembrane manufacturers, including The Project Material Co., Ltd. (BPM Geosynthetics), evaluated for their expertise, product quality, and innovation. Our goal is to provide actionable insights to help you choose the best supplier for your project needs.

1. Understanding HDPE Geomembranes

What Are HDPE Geomembranes?

HDPE geomembranes are impermeable liners made from high-density polyethylene, known for their high tensile strength (20–40 MPa), chemical resistance, and UV stability. Available in thicknesses from 0.5 to 3.0 mm, they are used in applications requiring robust containment, such as landfill liners, pond liners, and mining heap leach pads. Their impermeability (permeability coefficient <10⁻¹² cm/s) ensures minimal leakage, making them ideal for environmental protection.

Importance in Modern Applications

HDPE geomembranes are vital for sustainable infrastructure. A 2022 study found that HDPE liners reduce landfill leachate leakage by 99.9%, protecting groundwater. In mining, they increase ore recovery efficiency by 10–15% by preventing solution loss. Their durability, with lifespans exceeding 50 years under proper conditions, reduces maintenance costs by 20–30%. Choosing a manufacturer with high-quality HDPE geomembranes ensures compliance with environmental regulations and long-term project success.

2. Criteria for Selecting an Global HDPE Geomembrane Manufacturers

When choosing a manufacturer, consider these key factors:

- Product Quality: Compliance with ASTM D5199 and GM13 standards ensures thickness consistency and durability.

- Customization: Tailored thicknesses, widths (up to 8 m), and textures (smooth or textured) meet specific project needs.

- Global Reach: A robust supply chain ensures timely delivery across regions.

- Sustainability: Eco-friendly production and recyclable materials align with environmental standards.

- Certifications: ISO 9001, ISO 14001, and CE certifications indicate quality and environmental compliance.

- Technical Support: Expertise in installation and project consultation enhances outcomes.

These criteria guide our selection of the top 7 manufacturers, ensuring they deliver value and reliability.

3. Top 7 Global HDPE Geomembrane Manufacturers

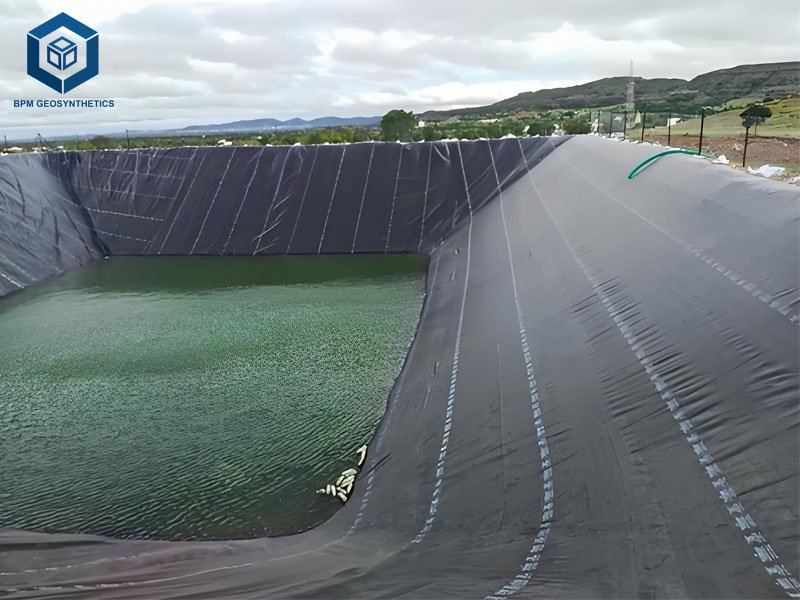

3.1 Global HDPE Geomembrane Manufacturers – The Project Material Co., Ltd. (BPM Geosynthetics)

City & Country: Shandong, China

Established Date: 2007

BPM Geosynthetics is a leading manufacturer of HDPE geomembranes, producing 12 million square meters annually and serving 80+ countries. Their geomembranes, compliant with ASTM GM13, range from 0.5–3.0 mm in thickness and are used in landfills, aquaculture, and water management. BPM’s advanced extrusion technology ensures uniform thickness and tensile strength up to 30 MPa.

Key Products:

- Smooth HDPE Geomembranes: For landfill liners, with permeability <10⁻¹³ cm/s.

- Textured HDPE Geomembranes: Enhanced friction for slope stability, with thicknesses up to 2.5 mm.

Pros:

- Customizable widths (2–8 m) and textures.

- Fast delivery (7–15 days).

- ISO 9001, ISO 14001, and CE certified.

Cons:

- Minimum order quantities (10,000 m²) may challenge small projects.

Takeaway Note: BPM Geosynthetics excels in high-quality, customizable HDPE geomembranes, ideal for large-scale environmental projects, though smaller buyers may need to negotiate MOQs.

3.2 Global HDPE Geomembrane Manufacturers – Shandong Geosino New Material Co., Ltd (Geosincere)

City & Country: Shandong, China

Established Date: 2010

Geosincere specializes in eco-friendly HDPE geomembranes, with an annual capacity of 8 million square meters. Serving North America and Europe, they use 25% recycled HDPE to reduce environmental impact. Their geomembranes, with thicknesses from 0.75–2.5 mm, meet GM13 standards and are used in mining and wastewater treatment.

Key Products:

- Smooth HDPE Geomembranes: For water containment, with tensile strength up to 28 MPa.

- Textured HDPE Geomembranes: For landfill slopes, with friction angles up to 30°.

Pros:

- Low MOQs (5,000 m²) suit mid-sized projects.

- Sustainable production with recycled materials.

- Global shipping (10–20 days).

Cons:

- Higher costs due to eco-friendly materials.

Takeaway Note: Geosincere’s sustainable focus and flexible MOQs make it ideal for environmentally conscious projects, though pricing may be higher for budget-limited buyers.

3.3 Global HDPE Geomembrane Manufacturers – Solmax

City & Country: Montreal, Canada

Established Date: 1981

Solmax, a global leader, produces 15 million square meters of HDPE geomembranes annually, serving 90 countries. Acquired GSE Environmental in 2021, expanding its portfolio. Their geomembranes, with thicknesses from 0.5–3.0 mm, are used in landfills, mining, and oil containment, meeting ASTM GM13 standards.

Key Products:

- GSE HDPE Geomembranes: Smooth and textured, with permeability <10⁻¹³ cm/s.

- Conductive HDPE Liners: For leak detection in landfills.

Pros:

- Extensive global network ensures reliable delivery.

- Advanced conductive liners for quality assurance.

- ISO 9001 and ISO 14001 certified.

Cons:

- Premium pricing may not suit small budgets.

Takeaway Note: Solmax’s advanced technology and global reach make it a top choice for large projects, but cost-conscious buyers may need alternatives.

3.4 Global HDPE Geomembrane Manufacturers – AGRU America, Inc.

City & Country: Georgetown, South Carolina, USA

Established Date: 1988

AGRU America produces 10 million square meters of HDPE geomembranes annually, focusing on high-performance liners for environmental applications. Their products, with tensile strengths up to 35 MPa, are used in 70 countries for landfills and water containment.

Key Products:

- MicroSpike® HDPE Geomembranes: Textured for enhanced friction (up to 35°).

- Super Gripnet® Liners: For steep slopes, with thicknesses up to 2.5 mm.

Pros:

- High durability for extreme environments.

- ISO 9001 certified.

- Customizable textures and widths (up to 7 m).

Cons:

- Limited focus on smaller projects.

Takeaway Note: AGRU’s specialized textured liners are ideal for challenging terrains, but their focus on large projects may limit accessibility for smaller firms.

3.5 Global HDPE Geomembrane Manufacturers – Atarfil

City & Country: Granada, Spain

Established Date: 1995

Atarfil produces 9 million square meters of HDPE geomembranes annually, serving 60 countries. Their liners, compliant with GM13, range from 0.5–3.0 mm and are used in mining, landfills, and hydraulic works. Atarfil emphasizes sustainability, with 20% recycled content in select products.

Key Products:

- Atarfil HDPE Geomembranes: Smooth and textured, with permeability <10⁻¹² cm/s.

- SafeLiner®: Reinforced liners for high-risk containment.

Pros:

- Sustainable production practices.

- Fast delivery (10–15 days).

- CE and ISO certified.

Cons:

- Limited customization for niche applications.

Takeaway Note: Atarfil’s eco-friendly liners suit sustainable projects, but buyers needing highly specialized products may require more flexible suppliers.

3.6 Global HDPE Geomembrane Manufacturers – NAUE GmbH & Co. KG

City & Country: Espelkamp, Germany

Established Date: 1967

NAUE produces 8 million square meters of HDPE geomembranes annually, specializing in landfill and tunnel applications. Their Carbofol® liners, with thicknesses from 1.0–3.0 mm, meet ASTM GM13 standards and offer tensile strengths up to 32 MPa. NAUE serves 60 countries with robust technical support.

Key Products:

- Carbofol® HDPE Geomembranes: For landfill and water containment.

- Bentofix® Composites: HDPE with bentonite for enhanced sealing.

Pros:

- Innovative composite solutions.

- Strong technical support.

- ISO 9001 and CE certified.

Cons:

- Higher costs for composite liners.

Takeaway Note: NAUE’s advanced composites and expertise make it ideal for complex projects, though pricing may deter smaller buyers.

3.7 Global HDPE Geomembrane Manufacturers – Layfield Group

City & Country: Vancouver, Canada

Established Date: 1978

Layfield produces 7 million square meters of HDPE geomembranes annually, serving North America, Australia, and Europe. Their liners, with thicknesses from 0.5–2.5 mm, are used in mining and wastewater treatment, meeting GM13 standards.

Key Products:

- Enviro Liner® HDPE Geomembranes: Smooth and textured, with tensile strength up to 30 MPa.

- VaporFlex® Liners: For gas barrier applications.

Pros:

- Strong focus on North American markets.

- ISO 9001 certified.

- Competitive pricing for mid-sized projects.

Cons:

- Limited global reach compared to competitors.

Takeaway Note: Layfield’s cost-effective liners suit mid-sized projects, but their regional focus may limit availability for global buyers.

4. How to Find the Best HDPE Geomembrane Manufacturers

Research Online and Industry Reports

Use industry publications like Geosynthetics Magazine and ENR to identify reputable manufacturers. Review case studies and certifications (e.g., ISO 9001, GM13) to verify quality and reliability.

Evaluate Product Specifications

Compare thickness (0.5–3.0 mm), tensile strength (20–40 MPa), and permeability (<10⁻¹² cm/s) to ensure compatibility with project requirements. Request samples to test performance.

Assess Customization and MOQs

Manufacturers like Geosincere offer low MOQs (5,000 m²) and customizable widths (2–8 m). Confirm the ability to tailor textures or thicknesses for specific applications.

Check Sustainability and Certifications

Prioritize manufacturers with sustainable practices, like Geosincere’s 25% recycled HDPE or Atarfil’s eco-friendly production. Certifications ensure compliance with environmental and quality standards.

5. Pros and Cons of Partnering with HDPE Geomembrane Manufacturers

Pros

- High Durability: HDPE geomembranes last 50+ years, reducing maintenance costs by 20–30%.

- Customization: Manufacturers like BPM offer tailored thicknesses and textures.

- Sustainability: Eco-friendly options align with regulations like EPA standards.

- Global Availability: Solmax and NAUE deliver to 60–90 countries within 10–15 days.

Cons

- Higher Costs for Premium Products: Textured or composite liners can increase costs by 10–20%.

- MOQ Challenges: BPM’s 10,000 m² minimums may not suit small projects.

- Lead Times: International shipping (10–20 days) may delay urgent projects.

6. What to Consider Before Partnering with HDPE Geomembrane Manufacturers

Project Requirements

Match manufacturer capabilities to your needs. For landfill liners, Solmax’s conductive liners ensure leak detection. For mining, AGRU’s textured liners provide slope stability.

Budget and MOQs

Balance quality with cost. Geosincere’s low MOQs suit smaller budgets, while Solmax’s premium liners are ideal for large projects with higher funding.

Logistics and Delivery

Choose manufacturers with efficient supply chains. BPM and NAUE deliver globally within 10–15 days, minimizing delays. Verify shipping costs for your region.

Sustainability and Compliance

Select manufacturers with eco-friendly practices and certifications. Geosincere and Atarfil reduce environmental impact by 20–25% with recycled materials, ensuring compliance with regulations.

7. Conclusion

Choosing the right HDPE geomembrane manufacturer is critical for environmental and civil engineering projects. The top 7 manufacturers—BPM Geosynthetics, Geosincere, Solmax, AGRU America, Atarfil, NAUE, and Layfield—offer high-quality, customizable solutions for diverse applications. BPM and Geosincere excel in flexibility and sustainability, while Solmax and NAUE provide advanced technology and global reach. By evaluating product specifications, MOQs, and logistics, you can select a manufacturer that aligns with your project goals. Contact BPM Geomembrane for quotes and samples to ensure optimal performance and value.