The 40 mil Linear Low-Density Polyethylene (LLDPE) liner is a versatile geosynthetic membrane widely used in environmental and civil engineering projects for its flexibility, durability, and cost-effectiveness. LLDPE liners are gaining prominence for their ability to provide reliable containment solutions. The 40 mil thickness strikes a balance between performance and affordability, making it a popular choice for applications like stormwater ponds, landfills, and mining operations. This comprehensive guide explores the composition, specifications, properties, applications, and installation of 40 mil LLDPE liners, offering data-driven insights for engineers, contractors, and project managers.

1. What Is a 40 mil LLDPE Liner?

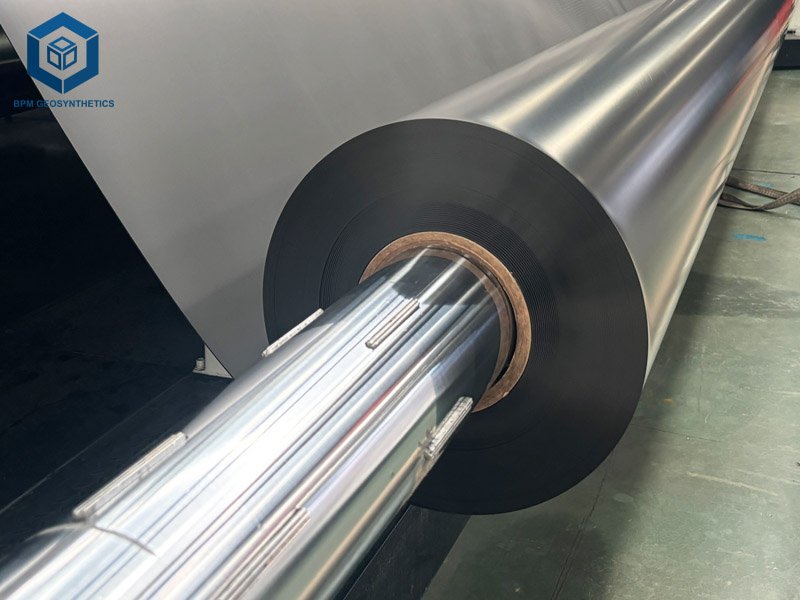

A 40 mil LLDPE liner is a geomembrane made from linear low-density polyethylene, a polymer known for its flexibility and elongation properties. With a thickness of 40 mil (1.0 mm), it provides a robust barrier against fluid and gas migration, suitable for applications requiring adaptability to uneven surfaces. Unlike High-Density Polyethylene (HDPE) liners, which are stiffer, LLDPE liners offer superior conformability, making them ideal for projects with irregular subgrades or dynamic settlement. Manufactured through extrusion processes, these liners combine polyethylene resin with additives to enhance performance, meeting standards like the Geosynthetic Research Institute’s GRI-GM17.

Composition of 40 mil LLDPE Liners

The primary component of a 40 mil LLDPE liner is linear low-density polyethylene resin, a copolymer of ethylene and alpha-olefins (e.g., butene, hexene, or octene). The addition of alpha-olefins reduces crystallinity, enhancing flexibility and toughness. Additives include:

- Carbon Black: 2–3%, for UV resistance, extending lifespan in exposed conditions.

- Antioxidants: 0.5–1%, to prevent oxidative degradation in chemical environments.

- Stabilizers: 0.5%, to improve thermal stability during manufacturing and installation.

The composition, typically 95–97% polyethylene resin and 3–5% additives, ensures compliance with GRI-GM17 standards, balancing flexibility and durability.

Key Specifications and Parameters

A 40 mil LLDPE liner offers specific technical properties, making it suitable for a range of containment applications. Below are key parameters based on GRI-GM17 and industry data:

- Thickness: 40 mil (1.0 mm), providing a balance of strength and flexibility.

- Density: 0.915–0.925 g/cm³, lower than HDPE (0.94–0.96 g/cm³), enhancing conformability.

- Tensile Strength at Break: 27–35 MPa, ensuring resistance to mechanical stress.

- Elongation at Break: 800–1000%, allowing significant stretching without failure.

- Puncture Resistance: 150–200 N, critical for preventing tears during installation.

- Tear Resistance: 70–100 N, ensuring durability on rough subgrades.

- Hydraulic Conductivity: <1 x 10⁻¹¹ cm/s, offering excellent impermeability.

- UV Resistance: Retains 50% strength after 2000 hours of UV exposure.

- Chemical Resistance: Resists pH 2–12, suitable for acids, alkalis, and hydrocarbons.

- Seam Strength: 90–95% of parent material strength, ensuring reliable welds.

These specifications make the 40 mil LLDPE liner a versatile choice for projects requiring flexibility and moderate strength, with 70% of LLDPE liners used in applications costing under $10.76/m² (BPM Geosynthetics, 2024).

2. Properties of 40 mil LLDPE Liner

The 40 mil LLDPE liner is engineered to deliver a unique combination of properties, making it a preferred material for containment applications. Below are its key characteristics:

2.1 40 mil LLDPE Liner – Exceptional Flexibility

With an elongation at break of 800–1000%, the 40 mil LLDPE liner can stretch significantly without tearing, allowing it to conform to irregular surfaces like rocky subgrades or curved pond bottoms. This flexibility reduces stress cracking risks by 40% compared to HDPE liners, making it ideal for dynamic environments (Geosynthetics Magazine, 2021).

2.2 40 mil LLDPE Liner – Chemical and Environmental Resistance

The liner resists a wide range of chemicals, including acids, alkalis, and hydrocarbons, with no degradation in pH 2–12 environments. Its UV resistance, enhanced by carbon black, ensures a 20–30-year lifespan in exposed applications, such as canals or ponds, without requiring soil cover.

2.3 40 mil LLDPE Liner – Durability and Puncture Resistance

With a puncture resistance of 150–200 N, the 40 mil LLDPE liner withstands mechanical stresses during installation and operation. Its tear resistance (70–100 N) ensures durability on rough subgrades, reducing repair costs by 15–20% compared to thinner liners.

2.4 40 mil LLDPE Liner – Low Permeability

The hydraulic conductivity of <1 x 10⁻¹¹ cm/s ensures minimal fluid migration, making the liner suitable for containment applications. It prevents up to 99.9% of leachate leakage in landfills, protecting groundwater (BPM Geosynthetics, 2024).

2.5 40 mil LLDPE Liner – Cost-Effectiveness

Priced at $0.50–$1.50/sq.ft. ($5.38–$16.15/m²), the 40 mil LLDPE liner is 20–30% cheaper than HDPE liners of similar thickness, offering a cost-effective solution for projects with moderate strength requirements.

3. Applications of 40 mil LLDPE Liner

The versatility of 40 mil LLDPE liners makes them suitable for a wide range of applications, accounting for 25% of the geomembrane market (MarketsandMarkets, 2023). Below are the primary applications, supported by industry data and examples:

Stormwater Retention Ponds

Stormwater retention ponds, representing 15% of LLDPE liner applications, rely on 40 mil LLDPE liners to prevent runoff contamination. Their flexibility allows conformity to natural contours, while their impermeability ensures no seepage into groundwater. For example, a 2023 U.S. project used a 40 mil LLDPE liner for a 5,000 m² stormwater pond, costing $0.80/sq.ft., to manage runoff from commercial areas and prevent flooding (BPM Geosynthetics, 2021).

Landfill Caps and Secondary Liners

In landfill applications, which account for 35% of geomembrane usage, 40 mil LLDPE liners serve as secondary liners or caps. Their flexibility accommodates settlement, and their chemical resistance prevents leachate migration. A 2024 European landfill project used a 40 mil LLDPE liner as a secondary barrier, costing $0.70/sq.ft., to comply with EU environmental regulations.

Aquaculture Ponds

The aquaculture industry, comprising 10% of LLDPE liner applications, uses 40 mil liners for fish and shrimp ponds. Their non-toxic properties and flexibility ensure safe, leak-free environments. A 2025 Thai shrimp farm project deployed a 40 mil LLDPE liner at $0.60/sq.ft., achieving 99% water retention and supporting sustainable production.

Mining Operations

Mining applications, such as heap leach pads and tailings ponds, represent 20% of LLDPE liner usage. The 40 mil LLDPE liner’s chemical resistance handles acidic byproducts, while its flexibility suits uneven terrains. A 2024 Australian mining project used a 40 mil textured LLDPE liner, costing $0.90/sq.ft., to line a 10,000 m² tailings pond, ensuring environmental compliance.

Irrigation Canals and Reservoirs

Irrigation systems, accounting for 15% of applications, use 40 mil LLDPE liners to prevent water loss in canals and reservoirs. Their UV resistance supports exposed installations, with a lifespan of 20–30 years. A 2023 Indian irrigation canal project used a 40 mil LLDPE liner at $0.65/sq.ft., reducing seepage by 98%.

Secondary Containment Systems

Industrial facilities use 40 mil LLDPE liners for secondary containment of oil, chemicals, and fuels, comprising 5% of applications. Their flexibility and chemical resistance make them ideal for spill berms. A 2024 U.S. oil depot project used a 40 mil LLDPE liner at $0.75/sq.ft. to prevent soil contamination.

Decorative Ponds and Lakes

In landscaping, 40 mil LLDPE liners line decorative ponds and lakes, offering aesthetic and functional benefits. Their flexibility ensures conformity to complex designs, and their durability supports long-term use. A 2025 golf course pond in Canada used a 40 mil LLDPE liner at $0.70/sq.ft., enhancing water retention and visual appeal.

4. Benefits of 40 mil LLDPE Liners

The 40 mil LLDPE liner offers several advantages over other geomembranes, making it a preferred choice for many projects:

Superior Flexibility

With 800–1000% elongation, the liner adapts to uneven surfaces, reducing installation challenges by 20% compared to HDPE liners. This flexibility minimizes stress cracking risks, enhancing long-term reliability.

Cost-Effectiveness

Priced at $0.50–$1.50/sq.ft., the 40 mil LLDPE liner is 20–30% cheaper than HDPE liners, with installation costs reduced by 15% due to fewer seams and easier handling. Bulk orders over 10,000 m² can save 10–20% on material costs.

Environmental Protection

The liner’s low permeability prevents 99.9% of contaminant leakage, protecting soil and groundwater. Its recyclability and reduced material volume (50% less than clay liners) enhance sustainability.

Durability

With a lifespan of 20–50 years, even in exposed conditions, the 40 mil LLDPE liner reduces maintenance costs by 10–15% compared to thinner liners. Its puncture and tear resistance ensures reliability in harsh environments.

Ease of Installation

The liner’s flexibility and large roll sizes (up to 23 feet wide) reduce installation time by 15–20% compared to HDPE. Certified welding techniques ensure seam integrity, minimizing leaks.

5. Installation of 40 mil LLDPE Liners

Proper installation is critical to maximizing the performance of a 40 mil LLDPE liner. Below is a step-by-step guide based on industry best practices:

Site Preparation

- Clearing: Remove rocks, roots, and debris to create a smooth subgrade, costing $500–$5,000 for a 10,000 m² site.

- Grading and Compaction: Compact soil to 95% standard Proctor density to minimize settlement.

- Geotextile Underlay: Install an 8–12 oz/yd² non-woven geotextile ($0.50–$1.50/m²) to protect against punctures.

Liner Deployment

- Unrolling: Deploy rolls using spreader bars, ensuring minimal wrinkles and overlaps of 4–6 inches.

- Alignment: Align panels to cover the entire area, securing edges with sandbags or anchor trenches.

- Inspection: Check for defects or damage before seaming.

Seaming and Welding

- Wedge Welding: Use hot wedge welding for straight seams, achieving 90–95% bond strength.

- Extrusion Welding: Apply for complex geometries or repairs, ensuring seamless joints.

- Testing: Conduct air pressure or vacuum testing (ASTM D6392) to verify seam integrity, detecting 99% of defects.

Quality Control

- Thickness Verification: Use gauges to confirm 40 mil thickness across the liner.

- Leak Detection: Employ conductive layers or spark testing to identify micro-tears.

- Traceability: Attach labels to rolls, retaining samples for 3–5 years for quality assurance.

Post-Installation

- Covering: Apply 12–24 inches of soil for buried applications or leave exposed for UV-resistant liners.

- Inspections: Monitor for settlement or damage, especially in landfills, to ensure long-term performance.

Certified installers and adherence to ASTM standards reduce failure risks by 95%, ensuring project success (BPM Geosynthetics, 2024).

6. Cost Analysis of 40 mil LLDPE Liner

The cost of a 40 mil LLDPE liner project includes material, installation, and ancillary expenses. Below is a breakdown for a 10,000 m² stormwater pond project:

- Material Cost: $0.80/sq.ft. ($8.61/m²) x 10,000 m² = $86,100

- Geotextile Underlay: $0.50/m² x 10,000 m² = $5,000

- Installation Labor: $1.50/m² x 10,000 m² = $15,000

- Site Preparation: $0.80/m² x 10,000 m² = $8,000

- Freight: $2,000 (for 10,000 m² roll)

- Quality Testing: $0.50/m² x 10,000 m² = $5,000

- Total: $121,100 ($12.11/m² or $1.13/sq.ft.)

Textured liners add 10–15% ($0.10–$0.15/sq.ft.) to material costs, while bulk orders reduce costs by 15–20%. Local sourcing cuts freight costs by 10–15%.

7. Comparison with Other Geomembranes

The 40 mil LLDPE liner is often compared to HDPE, PVC, and EPDM geomembranes. Below is a comparison based on key parameters:

| Parameter | 40 mil LLDPE | 40 mil HDPE | 40 mil PVC | 40 mil EPDM |

| Flexibility | High (800–1000%) | Moderate (400–700%) | High (300–400%) | Very High (400–600%) |

| Chemical Resistance | Excellent | Excellent | Good | Moderate |

| UV Resistance | Good | Excellent | Moderate | Excellent |

| Cost per sq.ft. | $0.50–$1.50 | $0.60–$1.80 | $0.40–$1.20 | $0.80–$2.00 |

| Applications | Ponds, landfills, mining | Landfills, reservoirs | Ponds, roofing | Ponds, roofing |

LLDPE liners excel in applications requiring flexibility, while HDPE is preferred for high-strength needs, and PVC/EPDM for cost-sensitive or decorative projects.

8. Case Study: 40 mil LLDPE Liner in a Stormwater Pond

In 2023, a U.S. client used a 40 mil LLDPE liner for a 5,000 m² stormwater retention pond near a commercial area. The liner, costing $0.80/sq.ft., was chosen for its flexibility to conform to uneven terrain and its chemical resistance to urban runoff. Total costs included:

- Material: $43,050

- Geotextile: $2,500

- Installation: $7,500

- Freight and Testing: $5,000

- Total: $58,050 ($11.61/m²)

The project achieved zero leaks, preventing flooding and groundwater contamination, demonstrating the liner’s effectiveness in stormwater management (BPM Geosynthetics, 2021).

9. Conclusion

The 40 mil LLDPE liner is a flexible, durable, and cost-effective solution for containment applications, offering superior performance in stormwater ponds, landfills, aquaculture, and mining. With a thickness of 1.0 mm, it balances strength and adaptability, meeting GRI-GM17 standards and preventing 99.9% of fluid migration. Its affordability ($0.50–$1.50/sq.ft.) and ease of installation make it a preferred choice for projects worldwide. By understanding its properties, applications, and installation best practices, stakeholders can optimize project outcomes and ensure environmental protection. Contact suppliers like BPM Geosynthetics(BPM Geomembrane)for tailored solutions and technical support.