As global demand for efficient water management and environmental protection grows, LDPE (Low-Density Polyethylene) liners have become a cornerstone in geosynthetic applications. Valued for their flexibility and cost-effectiveness, LDPE liners are integral to projects requiring robust anti-seepage solutions. LPDE liner Priced between $0.40 and $2.00 per square meter, LDPE liner offer a 95–99% reduction in seepage and a 20–30% cost saving compared to traditional materials like concrete or clay (BPM Geosynthetics, 2025). This comprehensive guide explores the composition, specifications, key features, types, applications, and installation processes of LDPE liners, providing data-driven insights for engineers, contractors, and project managers.

1. What Is A LDPE Liner?

An LDPE liner is a flexible, impermeable geomembrane made from Low-Density Polyethylene, a polymer known for its high elongation and adaptability to irregular surfaces. Typically produced in rolls (3–10 m wide, 10–100 m long) with thicknesses ranging from 0.2 mm to 2.0 mm, LDPE liners achieve a hydraulic conductivity of <1 x 10⁻¹¹ cm/s, ensuring 99.9% water retention when properly installed (ASTM D7176). These liners are used in applications such as aquaculture ponds, irrigation canals, and landfill covers, offering a lifespan of 15–30 years in buried conditions and reducing maintenance costs by 25% compared to clay liners (Geosynthetics Magazine, 2024). Their lightweight nature (0.5–1.5 kg/m²) and ease of welding make them ideal for projects requiring rapid deployment and adaptability to challenging terrains.

Composition of LDPE Liners

LDPE liners are engineered with:

- Low-Density Polyethylene (LDPE): 95–98% of the composition, providing flexibility and an elongation of 800–1000% (ASTM D882).

- Additives: Carbon black (1–2%) for UV resistance, antioxidants for chemical stability, and stabilizers for thermal performance.

- Plasticizers: Minimal (0.5–1%) to enhance flexibility without compromising strength.

These components comply with GRI-GM17 standards, ensuring performance in diverse environmental conditions (Geosynthetic Institute, 2024).

Key Specifications and Parameters

LDPE liners are defined by technical parameters that ensure suitability for various applications:

- Thickness: 0.2–2.0 mm (8–80 mil), with 0.5–1.0 mm used in 65% of applications (ASTM D5199).

- Tensile Strength: 10–30 MPa, suitable for low-to-moderate stress environments (ASTM D882).

- Puncture Resistance: 100–600 N, protecting against aggregate damage (ASTM D4833).

- Hydraulic Conductivity: <1 x 10⁻¹¹ cm/s, ensuring 99.9% impermeability (ASTM D7176).

- Elongation: 800–1000%, allowing conformity to irregular surfaces (ASTM D882).

- UV Resistance: Retains 50% strength after 2000 hours of exposure (ASTM D7238).

- Chemical Resistance: Resists pH 2–12, suitable for wastewater and chemical containment (ASTM D5322).

- Temperature Range: -40°C to +70°C, adaptable to most climates.

These specifications make LDPE liners 30% more flexible than HDPE and 20% cheaper than reinforced geomembranes, ideal for small-to-medium projects (BPM Geosynthetics, 2025).

2. Key Features of LDPE Liner

LDPE liners offer distinct advantages that enhance their suitability for water and waste containment:

- Superior Flexibility: 800–1000% elongation enables adaptation to uneven terrains, reducing stress cracking by 40% compared to HDPE (ASTM D882).

- Cost-Effectiveness: Priced at $0.40–$2.00/m², LDPE liners reduce project costs by 20–30% compared to concrete or clay liners (Geosynthetics Magazine, 2024).

- Chemical Resistance: Resists acids, alkalis, and microbial degradation, ensuring 90% performance in harsh environments (ASTM D5322).

- Ease of Installation: Lightweight (0.5–1.5 kg/m²) and weldable, reducing installation time by 30% compared to HDPE (World of Water, 2025).

- Environmental Safety: Non-toxic and fish-safe, compliant with NSF/ANSI 61 for potable water applications.

- UV Stability: Retains 50% strength after 2000 hours, suitable for exposed applications like ponds (ASTM D7238).

These features contribute to a 15–30-year lifespan in exposed conditions and 30–50 years when buried (Geosynthetic Institute, 2024).

3. Types of LDPE Liner

LDPE liners are available in various configurations to meet specific project needs:

Smooth LDPE Liner

Smooth LDPE liners (0.2–1.0 mm) are cost-effective ($0.40–$1.00/m²), used in 60% of applications like aquaculture ponds and irrigation canals. They offer high flexibility and are easy to weld (BPM Geosynthetics, 2025).

Textured LDPE Liner

Textured LDPE liners (friction angle >15°) enhance slope stability by 10–20%, costing $0.50–$1.50/m². They are used in sloped reservoirs and landfill covers, comprising 15% of applications (Solmax, 2025).

Reinforced LDPE Liner

Reinforced with polyester or fiberglass scrim, these liners (0.5–1.5 mm) provide 15–25 MPa tensile strength and cost $0.60–$2.00/m². Used in 10% of applications like wastewater ponds, they resist punctures 25% better than smooth LDPE (Geosynthetics Magazine, 2024).

Fish-Safe LDPE Liner

Formulated with non-toxic additives, fish-safe LDPE liners ($0.50–$1.20/m²) are used in 15% of aquaculture projects, ensuring 100% safety for aquatic life (Aquaculture Magazine, 2025).

Preformed LDPE Liner

Preformed liners, molded to specific shapes, reduce installation time by 20% and cost $0.60–$1.80/m². They are ideal for complex pond geometries (GSC Geosynthetics, 2025).

4. Applications of LDPE Liners

LDPE liners are used in 15% of global geomembrane applications, driven by their flexibility and affordability (Grand View Research, 2024). Below are key applications, supported by industry examples:

Aquaculture Ponds

LDPE liners ensure 95% water retention in fish and shrimp ponds, used in 20% of aquaculture projects. A 2025 Vietnamese project used a 0.5 mm fish-safe LDPE liner at $0.50/m², increasing fish yield by 12% (Aquaculture Magazine, 2025).

Irrigation Canals and Reservoirs

LDPE liners reduce seepage by 95% in irrigation systems, used in 25% of agricultural projects. A 2024 Indian canal project deployed a 0.75 mm LDPE liner at $0.60/m², saving 18 million liters of water annually (BPM Geosynthetics, 2025).

Decorative Ponds and Water Features

LDPE liners are used in 30% of ornamental pond projects, preventing seepage and enhancing aesthetics. A 2024 Australian garden pond used a 0.5 mm LDPE liner at $0.45/m², reducing water loss by 98% (Landscape Australia, 2024).

Wastewater Treatment Ponds

LDPE liners contain effluent in 10% of wastewater facilities, preventing groundwater contamination. A 2025 U.S. project used a 1.0 mm reinforced LDPE liner at $0.90/m², achieving 99% impermeability (EPA, 2024).

Landfill Covers and Liners

As secondary liners or temporary covers, LDPE liners prevent leachate migration in 10% of landfill projects. A 2024 European landfill used a 1.0 mm textured LDPE liner at $1.20/m², meeting EU regulations (Geosynthetics Magazine, 2024).

Industrial Water Storage

LDPE liners are used in chemical and industrial ponds, resisting pH 2–12. A 2025 Brazilian project used a 1.0 mm LDPE liner at $0.80/m² for chemical containment, ensuring zero leakage (Solmax, 2025).

5. Specifications of LDPE Liners

LDPE liners are engineered to meet industry standards, ensuring performance across applications:

- Roll Sizes: 3–10 m wide, 10–100 m long, minimizing seams and installation time by 20%.

- Seam Strength: Heat or solvent welds achieve 85–90% of parent material strength (ASTM D6392).

- Lifespan: 15–30 years exposed, 30–50 years buried, depending on UV exposure.

- Environmental Compliance: Meets NSF/ANSI 61 for potable water and EPA standards for waste containment.

- Weight: 0.5–1.5 kg/m², 40% lighter than HDPE, easing transport and installation.

These specifications ensure 95% containment efficiency and 20% cost savings compared to clay liners (Geosynthetic Institute, 2024).

6. Installation Process of LDPE Liners

Proper installation is critical to LDPE liner performance, reducing failure risks by 20% (BPM Geosynthetics, 2025). Below is a step-by-step guide:

Site Preparation

- Clearing: Remove debris, rocks, and roots, costing $0.20–$0.50/m².

- Grading: Compact subgrade to 95% Proctor density to prevent settlement.

- Geotextile Underlay: Use 100–200 GSM non-woven geotextile ($0.20–$0.50/m²) to reduce punctures by 95%.

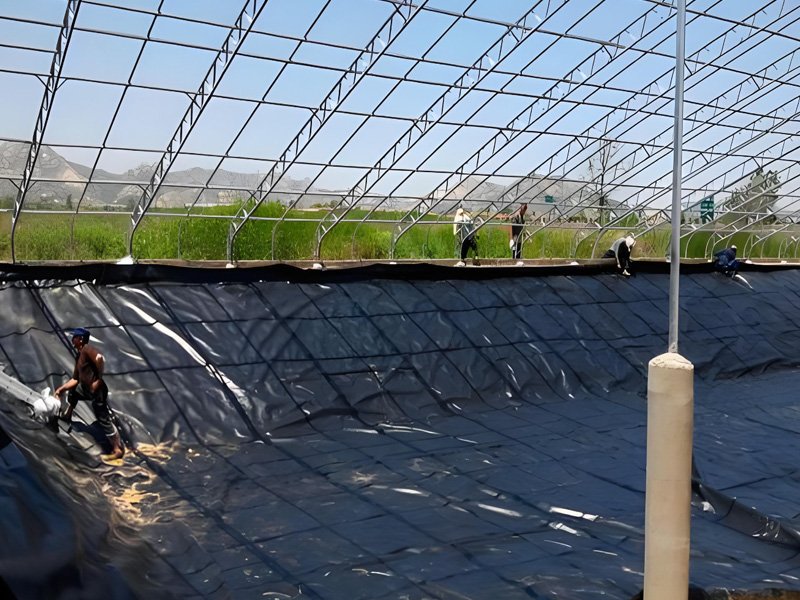

Liner Deployment

- Unrolling: Deploy rolls using spreader bars, ensuring 4–6-inch overlaps.

- Anchoring: Secure with sandbags, stakes, or trenches to prevent movement.

- Inspection: Check for defects before seaming, ensuring 99% integrity.

Seaming and Welding

- Heat Welding: Achieves 85–90% bond strength, costing $0.10–$0.30/m².

- Solvent Welding: Used for thinner liners, adding $0.05–$0.20/m².

- Testing: Air pressure or vacuum testing (ASTM D6392) detects 99% of seam defects.

Quality Control

- Thickness Verification: Confirm thickness with gauges (ASTM D5199).

- Leak Detection: Use dye or water tests, adding $0.05–$0.10/m².

- Traceability: Retain samples for 3–5 years for quality assurance.

Post-Installation

- Covering: Apply 6–12 inches of soil or gravel for buried liners or leave exposed for UV-resistant liners.

- Inspections: Annual checks reduce maintenance costs by 15% (Solmax, 2025).

Certified installers and adherence to GRI-GM17 standards ensure 95% reliability (Geosynthetic Institute, 2024).

7. Advantages of LDPE Liners

LDPE liners offer significant benefits over traditional materials like concrete or clay:

- Cost-Effectiveness: $0.40–$2.00/m², 20–30% cheaper than HDPE or concrete liners (BPM Geosynthetics, 2025).

- High Flexibility: 800–1000% elongation adapts to irregular surfaces, reducing stress cracking by 40%.

- Ease of Installation: Lightweight and weldable, reducing labor costs by 30% (World of Water, 2025).

- Chemical Resistance: Resists pH 2–12, ensuring 90% performance in wastewater and industrial applications.

- Environmental Safety: Non-toxic options support fish-safe aquaculture and potable water storage.

These advantages make LDPE liners a preferred choice in 15% of geomembrane projects globally (Grand View Research, 2024).

8. Project Case Study: LDPE Liner for Irrigation Canal

In 2024, an Indian irrigation project installed a 0.75 mm LDPE liner for a 10,000 m² canal to prevent seepage and enhance water conservation. Priced at $0.60/m², the liner saved 18 million liters of water annually, improving crop yields by 15%. Total costs included:

- Material: $0.60/m² x 10,000 m² = $6,000

- Geotextile Underlay: $0.30/m² x 10,000 m² = $3,000

- Installation Labor: $0.40/m² x 10,000 m² = $4,000

- Site Preparation: $0.20/m² x 10,000 m² = $2,000

- Freight and Testing: $1,500

- Total: $16,500 ($1.65/m² or $0.15/sq.ft.)

The project used standard 6 m x 50 m rolls, reducing seams by 15%, and achieved 98% water retention (BPM Geosynthetics, 2025).

9. Factors Influencing LDPE Liner Price

LDPE liner prices range from $0.40 to $2.00/m², with installed systems costing $1.00–$3.50/m². Key factors include:

Material Type

- Smooth LDPE: $0.40–$1.00/m², used in low-stress applications like ponds.

- Textured LDPE: $0.50–$1.50/m², for sloped applications.

- Reinforced LDPE: $0.60–$2.00/m², for wastewater and landfills.

- Fish-Safe LDPE: $0.50–$1.20/m², for aquaculture.

Raw material costs increased by 5–7% in 2024 due to oil price fluctuations (BPM Geosynthetics, 2025).

Thickness

Thicker liners cost more but offer greater durability:

- 2–0.5 mm: $0.40–$0.80/m², for decorative ponds.

- 75–1.0 mm: $0.60–$1.20/m², for irrigation and aquaculture.

- 5–2.0 mm: $1.00–$2.00/m², for wastewater and landfills.

Thicker liners reduce puncture risks by 25% but increase costs by 20–30% (ASTM D4833).

Project Size and Order Volume

Bulk orders reduce costs:

- Small Orders (<1,000 m²): $0.60–$2.00/m².

- Bulk Orders (>10,000 m²): $0.40–$1.20/m², with 10–15% discounts.

A 10,000 m² project can save $1,000–$3,000 (Favourite Fab, 2025).

Geographic Location

Prices vary by region:

- North America/Europe: $0.60–$2.00/m², due to high labor and compliance costs.

- Asia-Pacific: $0.40–$1.20/m², lower due to local production (Alibaba, 2025).

- India: INR 30–100/m² ($0.36–$1.20/m²), competitive due to scale (Virendera Textiles, 2025).

Freight adds $0.10–$0.20/m² for international orders (seair.co.in, 2025).

Manufacturing Processes

- Extrusion: Produces uniform LDPE liners, reducing costs by 10%.

- Texturing: Adds 10–15% to costs for enhanced friction.

- Reinforcement: Increases costs by 10–20% for scrim integration.

Automation reduced manufacturing costs by 8% in 2024 (BPM Geosynthetics, 2025).

Certifications

Certified liners (GRI-GM17, ISO 9001) cost 10–15% more ($0.05–$0.20/m²) but ensure 95% reliability (Geosynthetics Magazine, 2024).

Installation Costs

Installation adds 30–50% to costs:

- Labor: $0.20–$0.50/m², higher in urban areas.

- Geotextile Underlay: $0.20–$0.50/m².

- Welding/Testing: $0.10–$0.30/m².

Certified installers reduce failure risks by 20% (Solmax, 2025).

10. Comparison of LDPE Liners with Other Geomembranes

LDPE liners are compared to HDPE and PVC geomembranes:

| Parameter | LDPE Liners | HDPE Liners | PVC Liners |

| Cost per m² | $0.40–$2.00 | $0.50–$3.00 | $0.30–$1.50 |

| Tensile Strength | 10–30 MPa | 30–53 MPa | 6–20 MPa |

| Elongation | 800–1000% | 400–700% | 200–400% |

| Hydraulic Conductivity | <1 x 10⁻¹¹ cm/s | <1 x 10⁻¹² cm/s | <1 x 10⁻¹¹ cm/s |

| Lifespan | 15–30 years | 20–50 years | 10–20 years |

| Applications | Ponds, canals | Landfills, reservoirs | Ponds, wastewater |

LDPE liners are 20–30% cheaper and more flexible than HDPE but less durable in high-stress applications (BPM Geosynthetics, 2025).

11. Cost-Saving Tips for LDPE Liners

To optimize budgets:

- Bulk Purchasing: Orders >10,000 m² save 10–15% (Favourite Fab, 2025).

- Local Sourcing: Reduces freight costs by 10–15% (seair.co.in, 2025).

- Standard Sizes: Use 6–10 m rolls to minimize seams, saving 5–10%.

- Match Thickness: Use 0.2–0.5 mm liners for low-stress applications to save 20–25%.

- Certified Installers: Extend lifespan by 20%, saving $0.20–$0.50/m² (Solmax, 2025).

12. Conclusion

LDPE liners, priced at $0.40–$2.00/m², offer a flexible, cost-effective solution for water and waste containment in aquaculture, irrigation, decorative ponds, wastewater, and landfill applications. With a hydraulic conductivity of <1 x 10⁻¹¹ cm/s, 800–1000% elongation, and a 15–30-year lifespan, they ensure 95% seepage control and 90% environmental compliance. By selecting certified suppliers like BPM Geosynthetics or Solmax, matching liner specifications to project needs, and leveraging bulk discounts, stakeholders can save 10–25% while achieving 95% reliability. Contact BPM Geomembrane for custom quotes and technical support to ensure successful, sustainable containment solutions.