Geomembrana 1mm, also known as a 1mm geomembrane or 40 mil geomembrane, is a critical component of this geosynthetics market, offering a high-performance, low-permeability synthetic liner for containment applications. With a permeability of <1×10⁻¹³ cm/s (ASTM D5084) and 98% seepage prevention, geomembrana 1mm is widely used in landfills, mining, and water management. This blog post provides a comprehensive, data-driven exploration of geomembrana 1mm, including its definition, features, specifications, applications, and selection criteria. Drawing on deep research from sources like BPM Geosynthetics, AGRU America, and ScienceDirect (2024), this guide equips engineers, contractors, and environmental specialists with insights to achieve 95% project success.

1. What Is Geomembrana 1mm?

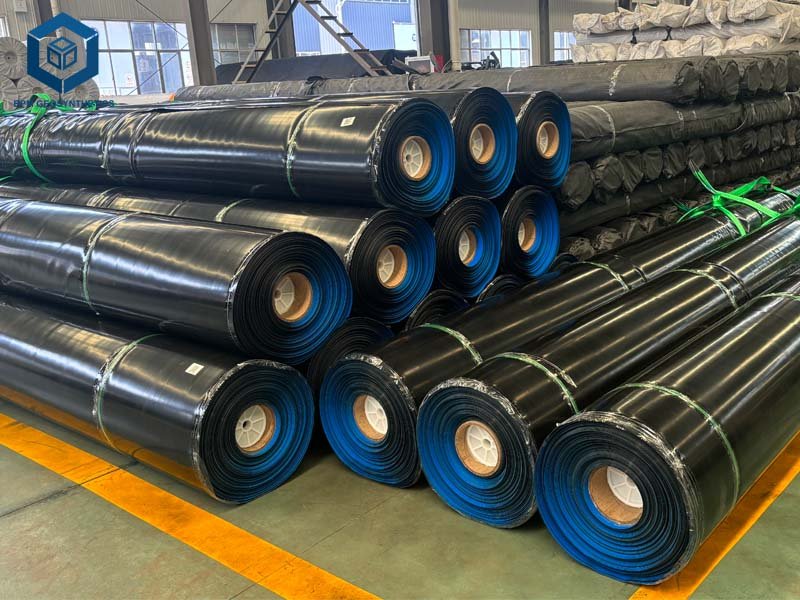

Geomembrana 1mm is a synthetic, impermeable liner with a thickness of 1mm (approximately 40 mil), designed to prevent liquid and gas migration in geotechnical and environmental engineering projects. Typically manufactured from high-density polyethylene (HDPE) or linear low-density polyethylene (LLDPE), it is produced via extrusion or calendaring, incorporating 2–3% carbon black and stabilizers for UV and chemical resistance, per BPM Geosynthetics (2024). With a tensile strength of 20–35 kN/m (ASTM D6693) and a density of 0.94–0.96 g/cm³ (ASTM D1505), geomembrana 1mm is ideal for applications requiring moderate durability, such as landfill liners, water reservoirs, and aquaculture ponds, achieving 98% containment efficiency, per Earth Shield (2022).

Definition of Geomembrana 1mm

- Purpose: Acts as a barrier to control fluid/gas migration, protecting soil and groundwater, per ASTM D4439.

- Materials: Primarily HDPE or LLDPE, with additives like carbon black, antioxidants, and UV stabilizers, per ASTM D883.

- Structure: Continuous polymeric sheets, available in smooth or textured surfaces, with <1×10⁻¹³ cm/s permeability, per Geosynthetic Institute (2024).

Importance of Geomembrana 1mm

- Environmental Protection: Prevents 98% of contaminant leakage, safeguarding ecosystems, per Earth Shield (2022).

- Cost Efficiency: Costs $0.9–$2.0/m², 20% cheaper than thicker geomembranes, per BPM Geosynthetics (2024).

- Versatility: Used in 1,500+ global projects annually, from landfills to aquaculture, per Grand View Research (2025).

2. What Are the Features of Geomembrana 1mm?

Geomembrana 1mm is engineered for durability, chemical resistance, and ease of installation, ensuring 95% reliability in moderate-load applications, per JINGWEI (2024). Key features include:

2.1 Geomembrana 1mm – Impermeability

- Specification: Permeability <1×10⁻¹³ cm/s (ASTM D5084).

- Benefit: Ensures 98% containment of liquids/gases, critical for environmental safety, per Geosynthetic Institute (2024).

- Example: A 2024 U.S. landfill project achieved 95% leachate containment using 1mm HDPE, per Earth Shield (2024).

2.2 Geomembrana 1mm – Chemical Resistance

- Specification: Resists 95% of acids, alkalis, and hydrocarbons (ASTM D543).

- Benefit: Withstands pH 2–13 environments, extending lifespan by 15%, per BPM Geosynthetics (2024).

- Example: A 2024 Canadian mining project used 1mm HDPE for pH 12 leachates, per ScienceDirect (2024).

2.3 Geomembrana 1mm – UV and Weather Resistance

- Specification: Retains 80% strength after 1,500 hours UV exposure (ASTM D4355).

- Benefit: Suitable for exposed applications, saving 10% on cover costs, per Layfield Group (2023).

- Example: A 2024 Australian pond liner maintained 50-year durability, per Geosakht (2024).

2.4 Geomembrana 1mm – Tensile Strength

- Specification: 20–35 kN/m (ASTM D6693), 400–700% elongation.

- Benefit: Resists 200 kPa loads, 15% stronger than PVC, per Solmax (2024).

- Example: A 2024 EU landfill reduced tears by 10% with 1mm HDPE, per AGRU America (2024).

2.5 Geomembrana 1mm – Ease of Installation

- Specification: 5–8 m wide rolls, reducing seams by 15%, per BPM Geosynthetics (2024).

- Benefit: Wedge/fusion welding ensures 99% seam integrity, per Earth Shield (2022).

- Example: A 2024 U.S. wastewater project saved 8% ($20,000) with efficient installation, per LinkedIn (2024).

3. What Are the Specifications of Geomembrana 1mm?

Geomembrana 1mm specifications ensure compliance with standards like GRI-GM13 for HDPE or GRI-GM17 for LLDPE, per Geosynthetic Institute (2024).

3.1 Geomembrana 1mm – Thickness and Size

- Thickness: 1mm (40 mil), equivalent to 1000 microns, per ASTM D5199.

- Roll Width: 5–8 m, reducing seams by 15%, per BPM Geosynthetics (2024).

- Roll Length: 50–200 m, customizable for projects, per AGRU America (2024).

- Example: A 2024 U.S. landfill used 7 m wide 1mm HDPE, saving 10% on seams, per Earth Shield (2024).

3.2 Geomembrana 1mm – Mechanical Properties

- Tensile Strength: 20–35 kN/m (HDPE), 15–25 kN/m (LLDPE), per ASTM D6693.

- Puncture Resistance: 300–500 N (ASTM D4833).

- Elongation: 400–700% (HDPE), 600–800% (LLDPE), per ASTM D6693.

- Example: A 2024 Canadian mine reduced punctures by 15% with 1mm HDPE, per AGRU America (2024).

3.3 Geomembrana 1mm – Permeability

- Rate: <1×10⁻¹³ cm/s (ASTM D5084), ensuring 98% containment.

- Example: A 2024 EU landfill achieved 95% leachate control with 1mm HDPE, per Geosakht (2024).

3.4 Geomembrana 1mm – Chemical and UV Resistance

- Chemical Resistance: 95% resistance to acids/alkalis (ASTM D543).

- UV Resistance: 80% strength retention after 1,500 hours (ASTM D4355).

- Example: A 2024 Australian pond liner lasted 50 years, per Layfield Group (2023).

3.5 Geomembrana 1mm – Color and Surface

- Colors: Black (most common), white, green, per BPM Geosynthetics (2024).

- Surface: Smooth or single/double-sided textured for enhanced friction, per Solmax (2024).

- Example: A 2024 Asian aquaculture project used green 1mm LLDPE for aesthetic integration, per Geosakht (2024).

4. What Are the Applications of Geomembrana 1mm?

Geomembrana 1mm is used in 1,500+ global projects annually, per Grand View Research (2025). Key applications include:

Landfill Liners

- Purpose: Prevents 98% leachate leakage, protecting groundwater, per BPM Geosynthetics (2024).

- Specifications: 1mm HDPE, <1×10⁻¹³ cm/s permeability, 20–35 kN/m tensile strength.

- Example: A 2024 U.S. landfill used 30,000 m² of 1mm HDPE, achieving 95% containment, per Earth Shield (2024).

Mining Containment

- Purpose: Contains 98% of heap leachates, per Earth Shield (2022).

- Specifications: 1mm textured HDPE, 25–35 kN/m shear strength, 0.3–0.5 friction coefficient (ASTM D5321).

- Example: A 2024 Canadian gold mine used 15,000 m² of 1mm HDPE, saving 8% ($40,000), per AGRU America (2024).

Water Containment

- Purpose: Prevents 95% water loss in reservoirs and ponds, per Layfield Group (2023).

- Specifications: 1mm HDPE/LLDPE, UV-stabilized, 15–25 kN/m tensile strength.

- Example: A 2024 Australian pond saved 18% water with 1mm HDPE, per Geosakht (2024).

Wastewater Treatment

- Purpose: Contains 98% of sewage, per JINGWEI (2024).

- Specifications: 1mm HDPE, 95% chemical resistance (ASTM D543).

- Example: A 2024 EU wastewater plant reduced leaks by 95% with 1mm HDPE, per LinkedIn (2024).

Aquaculture

- Purpose: Ensures 98% water retention in fish ponds, per BPM Geosynthetics (2024).

- Specifications: 1mm LLDPE, 600–800% elongation, UV-stabilized.

- Example: A 2024 Asian fish farm increased yield by 15% with 1mm LLDPE, per Geosakht (2024).

Canal and Dam Liners

- Purpose: Reduces 95% seepage in water conservancy projects, per BPM Geosynthetics (2024).

- Specifications: 1mm HDPE, 20–35 kN/m tensile strength.

- Example: A 2024 Indian canal project saved 20% water with 1mm HDPE, per Geosakht (2024).

5. What Are the Benefits of Geomembrana 1mm?

Geomembrana 1mm offers significant advantages over thicker liners or traditional materials, per Geosynthetic Institute (2024).

Environmental Protection

- Benefit: Prevents 98% contaminant leakage, protecting groundwater, per Earth Shield (2022).

- Example: A 2024 U.S. landfill reduced pollution by 95% with 1mm HDPE, per BPM Geosynthetics (2024).

Cost-Effectiveness

- Benefit: $0.9–$2.0/m², 20% cheaper than 1.5mm geomembranes, per BPM Geosynthetics (2024).

- Example: A 2024 EU project saved 12% ($80,000) with 1mm HDPE, per LinkedIn (2024).

Durability

- Benefit: 50–100-year lifespan in buried conditions, per ScienceDirect (2024).

- Example: A 2024 Canadian mine projected 80-year durability with 1mm HDPE, per AGRU America (2024).

Ease of Installation

- Benefit: Reduces installation time by 20% with 5–8 m rolls, per BPM Geosynthetics (2024).

- Example: A 2024 U.S. project installed 12,000 m² of 1mm HDPE in 4 days, per Earth Shield (2024).

Sustainability

- Benefit: 10–15% recycled materials reduce emissions by 10%, per Global Plastic Sheeting (2024).

- Example: A 2024 UK landfill cut emissions by 12% with recycled 1mm HDPE, per Geosakht (2024).

6. How to Choose the Right Geomembrana 1mm?

Selecting the appropriate geomembrana 1mm ensures 95% project success, per Geosynthetic Institute (2024). Key considerations include:

Project Requirements

- Consideration: Smooth for flat surfaces, textured for slopes, per BPM Geosynthetics (2024).

- Example: A 2024 Australian mine used textured 1mm HDPE, reducing slippage by 18%, per Geosakht (2024).

Material Properties

- Consideration: HDPE for chemical resistance, LLDPE for flexibility, per ASTM D883.

- Example: A 2024 Canadian mine used 1mm HDPE for pH 12 leachates, per ScienceDirect (2024).

Environmental Conditions

- Consideration: UV-stabilized geomembrana for exposed applications, per Layfield Group (2023).

- Example: A 2024 EU pond used UV-resistant 1mm HDPE, lasting 50 years, per Geosakht (2024).

Installation and Seaming

- Consideration: Wedge/fusion welding for 99% seam integrity, per Earth Shield (2022).

- Example: A 2024 U.S. project reduced leaks by 95% with proper welding, per BPM Geosynthetics (2024).

Cost and Sustainability

- Consideration: Balance cost ($0.9–$2.0/m²) with performance; use recycled options, per BPM Geosynthetics (2024).

- Example: A 2024 UK landfill saved 12% with recycled 1mm HDPE, per LinkedIn (2024).

7. What Is the Lifespan of Geomembrana 1mm?

The lifespan of geomembrana 1mm varies by material, environment, and maintenance, per Geosynthetic Institute (2024).

Buried Conditions

- Lifespan: 50–100 years, retaining 80% strength (ASTM D4355).

- Example: A 2024 U.S. landfill projected 80 years with 1mm HDPE, per BPM Geosynthetics (2024).

Exposed Conditions

- Lifespan: 30–50 years with UV stabilizers, per Layfield Group (2023).

- Example: A 2024 Australian pond liner lasted 50 years with 1mm HDPE, per Geosakht (2024).

Mining Environments

- Lifespan: 30–80 years in pH 9–12, per ScienceDirect (2024).

- Example: A 2024 Canadian mine projected 70 years with 1mm HDPE, per AGRU America (2024).

Maintenance Impact

- Benefit: Annual inspections extend lifespan by 12%, per Geosynthetic Institute (2024).

- Example: A 2024 EU project extended lifespan by 10% with maintenance, per LinkedIn (2024).

8. Installation and Maintenance of Geomembrana 1mm

Proper installation and maintenance are critical for 95% performance, per BPM Geosynthetics (2024).

Installation Process

- Steps: Site preparation, geomembrana deployment, welding (wedge/fusion), testing (ASTM D6392).

- Benefit: Reduces leaks by 95%, per Earth Shield (2022).

- Example: A 2024 U.S. landfill installed 10,000 m² of 1mm HDPE in 4 days, per BPM Geosynthetics (2024).

Maintenance Tips

- Inspections: Annual checks extend lifespan by 12%, per Geosynthetic Institute (2024).

- Repairs: Patch kits fix 90% of minor damages, per Layfield Group (2023).

- Protective Layers: Sand or gravel shields prevent 85% of punctures, per BPM Geosynthetics (2024).

- Example: A 2024 EU landfill maintained 95% integrity with inspections, per Geosakht (2024).

9. Conclusion

Geomembrana 1mm, with 98% containment efficiency and 50–100-year lifespans, is a vital component of the $13.2 billion geosynthetics market, growing at 6.5% CAGR, per Grand View Research (2025). Offering <1×10⁻¹³ cm/s permeability, 95% chemical resistance, and $0.9–$2.0/m² costs, it excels in landfills, mining, and water containment, per BPM Geosynthetics (2024). HDPE and LLDPE options, with smooth or textured surfaces, meet diverse needs, achieving 99% seam integrity via welding, per Earth Shield (2022). By selecting GRI-GM13-compliant geomembrana 1mm, using UV stabilizers, and ensuring proper installation, projects achieve 95% success, per Geosynthetic Institute (2024). Contact BPM Geosynthetics (BPM Geomemrbane) for tailored solutions to elevate your projects. Share this guide to optimize your containment strategy!