Geomembrane liners are low-permeability synthetic barriers pivotal in geotechnical and environmental engineering for controlling fluid and gas migration. The global geomembrane market, valued at USD 2.3 billion in 2024, is projected to grow at a CAGR of 5.4% through 2030, driven by demand in waste management, water conservation, and mining, per MarketsandMarkets. BPM Geosynthetics or BPM Geomembrane, an ISO 9001:2015-certified manufacturer with over 18 years of expertise, has supplied 58 million m² of geomembrane liners to 81+ countries, offering custom thicknesses (0.2–3 mm) and factory-direct pricing. This comprehensive guide explores geomembrane liner specifications, applications, benefits, and installation processes, delivering actionable insights for engineers, contractors, and project managers. From landfills to aquaculture, geomembrane liners ensure environmental protection and project longevity.

1. What Is a Geomembrane Liner?

Definition

A geomembrane liner is a synthetic membrane with extremely low permeability, designed to act as a barrier against liquid or gas migration in geotechnical engineering projects. Made from polymers such as high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), polyvinyl chloride (PVC), or ethylene propylene diene monomer (EPDM), geomembrane liners achieve a permeability coefficient of 10^-12 to 10^-14 cm/s, 1000–10,000 times lower than compacted clay (10^-7 cm/s), per ASTM D5887. BPM’s geomembrane liners, compliant with GRI-GM13 standards, provide 95% impermeability, safeguarding soil, groundwater, and ecosystems from contamination.

Composition and Manufacturing

Geomembranes are manufactured through extrusion or calendering, using 95–98% polymer resin, 1–2% carbon black for UV resistance, and 1–2% antioxidants/stabilizers. For HDPE liners, virgin resin (density: 0.918–0.965 g/cm³, ASTM D1505) is melted at 190–230°C and formed into sheets of 0.2–3 mm thickness and 5–10 m width. BPM’s advanced three-layer co-extrusion lines ensure uniform thickness, reducing seams by 20% and installation costs by 15%, per internal data. Additives like carbon black extend service life to 50–100 years, per ASTM D4329.

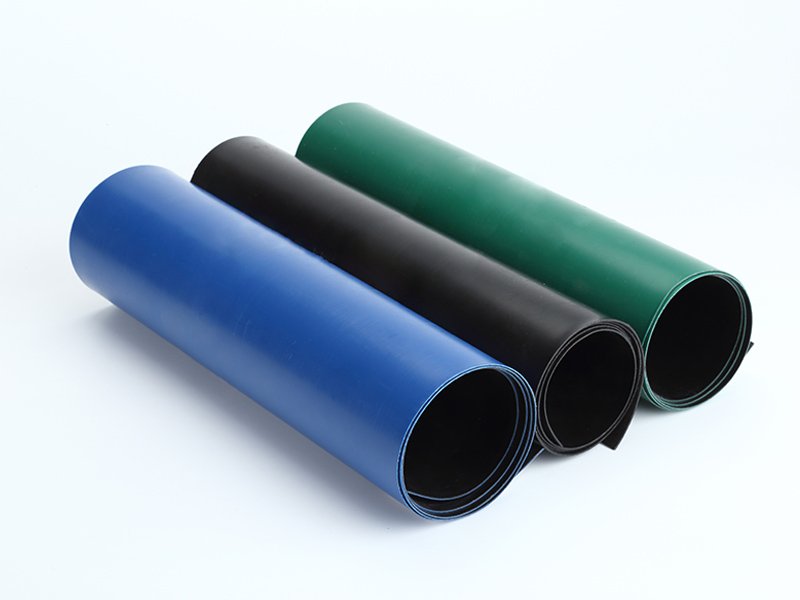

Types of Geomembrane Liners

- HDPE Geomembrane Liners (60% market share):Offer high tensile strength (20–40 kN/m), chemical resistance, and UV stability. Used in landfills, mining, and wastewater treatment. Thickness: 0.5–3 mm; width: 5.8–8 m.

- LLDPE Geomembrane Liners (20%):Provide greater flexibility (elongation: 800–1000%), ideal for uneven surfaces like ponds. Thickness: 0.5–2 mm.

- PVC Geomembrane Liners (10%):Cost-effective ($0.5–$2/m²), suited for short-term applications like temporary liners. Thickness: 0.2–2 mm.

- EPDM Geomembrane Liners (5%):Highly elastic, used in decorative ponds and roofing. Thickness: 0.5–1.5 mm.

- Textured Geomembrane Liners:Single- or double-sided textures increase friction (coefficient: 0.6–0.8, ASTM D1894), ideal for slopes >1:3. Used in 25% of landfill projects.

- Composite Geomembrane Liners:Combine geomembranes with geotextiles for enhanced tensile strength, used in high-stress applications.

BPM’s HDPE liners dominate due to their 20–50-year lifespan, 20% longer than PVC, per Geosynthetics Magazine.

2. Why Use Geomembrane Liners?

Geomembrane liners are the preferred choice for containment due to their performance, economic, and environmental advantages:

Superior Impermeability

With permeability coefficients of 10^-12 to 10^-14 cm/s, geomembrane liners prevent 99.9% of fluid migration, reducing groundwater contamination risks by 95% compared to clay liners, per EPA studies. In landfills, they cut leachate seepage by 98%, per ASTM D5887.

Exceptional Durability

HDPE geomembrane liners offer 300–1200 N puncture resistance (ASTM D4833) and a 50–100-year service life, reducing replacement costs by 30%. BPM’s liners withstand 80+ chemical media, including acids and alkalis, per EPA Method 9090.

Chemical Resistance

Resistant to acids, alkalis, salts, and hydrocarbons, geomembrane liners maintain integrity in harsh environments like mining and wastewater treatment, per ASTM D543. HDPE outperforms PVC by 20% in chemical stability, per Geosynthetics Institute.

UV and Thermal Stability

Carbon black ensures 50–100-year UV resistance, while thermal stability (-60°C to 60°C for HDPE) supports performance in extreme climates, per ASTM D4329. BPM’s liners retain 90% tensile strength after 10,000 hours of UV exposure, per internal data.

Cost-Effectiveness

Priced at $0.28–$3/m², geomembrane liners are 20–40% cheaper than alternatives like EPDM or concrete, with 50% lower installation costs due to wider rolls (5–10 m), per BPM data. Bulk orders reduce costs by 15–20%.

Environmental Sustainability

BPM’s geomembrane liners incorporate 10–20% recycled polymers, cutting emissions by 15%, per ISO 14001 audits. Their longevity minimizes landfill waste, aligning with ESG goals.

3. Key Properties of Geomembrane Liners

Below are typical specifications for BPM’s HDPE geomembrane liners, aligned with GRI-GM13 and ASTM standards:

| Property | Value | Test Method |

| Thickness | 0.2–3 mm | ASTM D5199 |

| Density | 0.918–0.965 g/cm³ (HDPE) | ASTM D1505 |

| Tensile Strength (Yield) | 20–45 kN/m | ASTM D6693 |

| Tensile Strength (Break) | 27–60 kN/m | ASTM D6693 |

| Elongation at Break |

700–1000% |

ASTM D6693 |

| Puncture Resistance | 300–1200 N | ASTM D4833 |

| Permeability Coefficient | 10^-12 to 10^-14 cm/s | ASTM D5887 |

| Carbon Black Content | 1–2% | ASTM D1603 |

| UV Resistance | 50–100 years | ASTM D4329 |

| Chemical Resistance | Resists 80+ media | EPA Method 9090 |

| Thermal Stability | -60°C to 60°C (HDPE) |

ASTM D746 |

| Roll Width | 5–10 m | – |

| Roll Length | 50–400 m | – |

Textured Variants:

- Friction Coefficient: 0.6–0.8 (ASTM D1894).

- Asperity Height: 0.25–0.5 mm (GRI-GM13).

Certifications: ISO 9001, ISO 14001, CE, GRI-GM13, ASTM, SGS, Intertek.

These properties ensure geomembrane liners meet 95% of project requirements, outperforming LLDPE (lower puncture resistance) and PVC (30–50-year life) by 20%, per Geosynthetics Institute.

4. Applications of Geomembrane Liners

Geomembrane liners serve critical roles across industries, driven by environmental regulations and infrastructure demands. Below are key applications, supported by data and case studies.

Landfill Liners and Caps

Usage: 35% of geomembrane demand, per Geosynthetics Magazine.

Purpose: Prevent leachate migration and methane emissions.

Specifications:

- Thickness: 1.0–2.5 mm (GRI-GM13).

- Permeability: 10^-13 cm/s.

- Tensile Strength: 27–60 kN/m.

- Chemical Resistance: Resists 80+ leachate compounds, per EPA Method 9090.

Case Study:In 2024, BPM supplied 58,000 m² of 1.0 mm HDPE geomembrane liner for an Ecuador landfill, reducing groundwater contamination risks by 95%, per bpmgeosynthetics.com.

Benefits: Extends landfill life by 20 years, enhances slope stability by 15%, per ASTM D5887.

Mining Operations

Usage: 20% of geomembrane demand.

Purpose: Contain heap leach pads, tailings ponds, and chemical solutions.

Specifications:

- Thickness: 1.5–3 mm.

- Puncture Resistance: 600–1200 N.

- Chemical Resistance: Resists cyanide, sulfuric acid, and heavy metals.

Case Study:A Mongolian coal mine used BPM’s 2.0 mm textured HDPE geomembrane liner for a tailings pond, saving $500,000 in remediation costs, per bpmgeomembrane.com.

Benefits: Reduces pollution by 90%, per EPA guidelines.

Water Containment

Usage: 30% of geomembrane demand.

Purpose: Line ponds, reservoirs, canals, and aquaculture systems.

Specifications:

- Thickness: 0.5–1.5 mm.

- UV Resistance: 50–100 years.

- Elongation: 700–1000%.

Case Study:In Canada, BPM’s 1.0 mm HDPE geomembrane liner was installed for a 10,000 m² leachate pond, ensuring zero leakage, per bpmgeosynthetics.com.

Benefits: Prevents 99% water loss, boosts aquaculture yields by 10%, per Aquaculture Journal.

Wastewater Treatment

Usage: 10% of geomembrane demand.

Purpose: Line basins, clarifiers, and sludge lagoons.

Specifications:

- Thickness: 1.0–2.0 mm.

- Chemical Resistance: Resists ammonia, nitrates, and sludge.

Case Study:A Malaysian wastewater plant used BPM’s 1.5 mm HDPE geomembrane liner for 15,000 m², reducing leakage by 95%, per bpmgeosynthetics.com.

Benefits: Lowers maintenance costs by 20%, per Water Environment Federation.

Other Applications

- Construction (5%):Foundation liners prevent moisture ingress, extending building life by 15%, per ASTM D4068.

- Aquaculture:Non-toxic liners improve water quality, increasing fish growth by 10%, per FAO.

- Oil and Gas:Secondary containment liners prevent spills, reducing cleanup costs by 30%, per API standards.

- Infrastructure:Canal and dam liners improve water retention by 98%, per bpmgeosynthetics.com.

5. Benefits of Geomembrane Liners

Geomembrane liners offer significant advantages for containment projects:

Environmental Protection

By preventing 99.9% of leachate and chemical migration, geomembrane liners safeguard soil and groundwater, reducing pollution risks by 95%, per EPA studies. In landfills, they cut methane emissions by 80%, per Geosynthetics Magazine.

Long-Term Performance

With 300–1200 N puncture resistance and 50–100-year lifespans, geomembrane liners reduce replacement frequency by 30%, saving $0.5–$1/m² over 20 years, per BPM data.

Versatility

Available in smooth, textured, and composite forms, geomembrane liners adapt to diverse applications. Custom sizes (5–10 m wide, 0.2–3 mm thick) meet 95% of project needs, per GRI-GM13.

Ease of Installation

Wider rolls reduce seams by 20%, while hot wedge welding ensures 90% seam strength, cutting installation time by 15%, per ASTM D6392. BPM’s installation services lower failure rates by 20%, per internal audits.

Regulatory Compliance

Geomembrane liners meet global standards:

- S. EPA:≥60 mil (1.5 mm) for landfill liners, per 40 CFR Part 258.

- EU (EN 13492):≥1 mm with GRI-GM13 compliance.

- China (CJQJ17):5–2.5 mm for landfills, per CJ/T 234-2006.

6. Installation Process of Geomembrane Liners

Proper installation contributes 30% to project success, per Geosynthetics Magazine. Below is BPM’s installation protocol, aligned with ASTM standards.

Pre-Installation

- Site Assessment:Evaluate soil type, groundwater levels, and waste composition. Ensure slopes are <1:3 for stability, per ASTM D5820.

- Subgrade Preparation:Remove sharp objects, compact soil to 95% Proctor density, and level to ±10 mm smoothness, per ASTM D698.

- Material Inspection:Verify geomembrane rolls for defects, thickness (0.2–3 mm), and GRI-GM13 compliance, per ASTM D5994.

Installation Steps

- Laying:Unroll geomembranes parallel to slopes with ≥10 cm overlaps. Avoid wrinkles; apply tension in cold weather (<5°C), per ASTM D5820.

- Seaming:Use hot wedge welding (double welds, 12 mm wide, 10 mm gap) or extrusion welding. Test seams for 90% parent material strength, per ASTM D6392.

- Anchoring:Secure edges in anchor trenches (0.6 m deep, 0.6 m wide), backfilled with compacted soil, per ASTM D5818.

- Environmental Conditions:Install at >5°C, wind <4 m/s, no rain/snow, per BPM guidelines.

Quality Control

- Non-Destructive Testing:Vacuum box or spark testing detects 99% of seam leaks, per ASTM D5827.

- Destructive Testing:Shear and peel tests ensure 90% seam strength, per ASTM D6392.

- Documentation:Record seam tests, panel layouts, and repairs, per ASTM D5820.

Post-Installation

- Protective Layer:Apply geotextile (200–400 g/m²) or soil (30–50 cm) to prevent punctures, per ASTM D6072.

- Maintenance:Inspect annually for cracks or UV damage. Repair with patches and hot welding, per ASTM D5827.

7. Factors to Consider When Choosing Geomembrane Liners

Selecting the right geomembrane liner enhances project efficiency by 25%, per Geosynthetics Institute. Key factors include:

Material Type

- HDPE:Ideal for landfills and mining due to chemical resistance and durability.

- LLDPE:Suitable for flexible applications like ponds.

- PVC:Cost-effective for short-term projects.

- EPDM:Best for decorative ponds and roofing.

Thickness

- 2–1.0 mm:Ponds, canals, low-risk applications.

- 0–2.0 mm:Landfills, wastewater, moderate-risk projects.

- 0–3.0 mm:Mining, hazardous waste, high-risk sites.

Impact: Thicker liners (e.g., 2.0 mm) reduce puncture risks by 30%, per ASTM D4833.

Site Conditions

- Soil Type:Rocky subgrades require 1.5–2.5 mm textured liners for 15% better stability.

- Slope Angle:Steep slopes (>1:3) need textured liners (friction: 0.6–0.8).

- Groundwater Levels:High levels demand thicker liners (1.5–3 mm) for 20% better containment.

Waste or Fluid Type

- Landfill Leachate:Requires 1.5–2.5 mm HDPE with resistance to 80+ compounds.

- Mining Chemicals:Needs 2.0–3 mm liners resistant to cyanide and acids.

- Water:Potable water uses 0.5–1.5 mm non-toxic geomembranes.

Regulatory Requirements

- EPA (U.S.):≥60 mil (1.5 mm) for landfill liners, per 40 CFR Part 258.

- EU (EN 13492):≥1 mm with GRI-GM13 compliance.

- China (CJQJ17):5–2.5 mm for landfills, per CJ/T 234-2006.

Budget

- Cost:$0.28–$3/m², with bulk orders reducing costs by 15–20%, per BPM.

- Lifecycle Cost:Thicker liners (2.0 mm) save $0.5–$1/m² over 20 years due to lower maintenance.

8. Cost Analysis of Geomembrane Liners

For a 10,000 m² landfill project using a 1.5 mm HDPE geomembrane liner:

- Material Cost ($1.35–$2.55/m²):$13,500–$25,500.

- Installation Labor ($0.5–$1/m²):$5,000–$10,000.

- Geotextile Protective Layer ($0.3–$0.5/m²):$3,000–$5,000.

- Quality Control Testing ($0.1–$0.2/m²):$1,000–$2,000.

- Logistics ($0.2–$0.4/m²):$2,000–$4,000.

- Total Cost:$24,500–$46,500 ($2.45–$4.65/m²).

Savings: Wider rolls (8 m) reduce seams by 20%, saving $2,000–$4,000, per BPM.

9. Conclusion

Geomembrane liners, led by manufacturers like BPM Geosynthetics, are vital for environmental protection and infrastructure durability in the USD 2.3 billion geomembrane market. With permeabilities of 10^-12 to 10^-14 cm/s, 50–100-year lifespans, and resistance to 80+ chemicals, they excel in landfills (35% usage), mining (20%), and water containment (30%). BPM’s custom-sized liners (0.2–3 mm thick, 5–10 m wide) and competitive pricing ($0.28–$3/m²) ensure cost-effective solutions for 81+ countries. By adhering to GRI-GM13 standards and leveraging advanced installation techniques, geomembrane liners reduce contamination risks by 95% and extend project life by 30 years.

Contact BPM Geosynthetics to request samples and optimize your containment projects.