High-Density Polyethylene (HDPE) pond liners, holding a 61% market share, are critical for preventing seepage in ponds, lakes, and reservoirs, offering a permeability coefficient of ≤1×10⁻¹³ cm/s and a 20–50-year lifespan (bpmgeosynthetics.com, 2025). HDPE pond liner price in 2025 range from $0.50 to $3.50 per square meter ($0.05–$0.33/ft²), influenced by thickness, roll size, installation complexity, and regional factors (bpmgeomembrane.com, 2025). These liners ensure 99.9% water retention, saving $100–$500 annually in water refilling costs for a 1,000 m² pond, and are 20–30% cheaper than concrete alternatives (GeoFanTex, 2024).

This guide provides a data-driven analysis of HDPE pond liner prices, specifications, and cost-saving strategies. Drawing on insights from and industry sources like Future Market Insights, we offer actionable advice for homeowners, farmers, and engineers. This 2,000+ word article equips readers to optimize budgets while ensuring durable, leak-proof pond solutions in the USD 2.57 billion geomembrane market.

1. What Is an HDPE Pond Liner?

An HDPE pond liner is a geomembrane made from high-density polyethylene resin, blended with 2–3% carbon black, antioxidants, and UV stabilizers, to create an impermeable barrier for water containment. With a density of 0.94–0.96 g/cm³, HDPE liners offer 15–20 MPa tensile strength (ASTM D412), 4409 N puncture resistance (ASTM D4833), and a hydraulic conductivity of ≤1×10⁻¹³ cm/s, ensuring 99.9% water retention (bpmgeosynthetics.com, 2025). Key features include:

- Durability: 20–50-year lifespan with 95% UV resistance for 15–20 years (ASTM D4355).

- Chemical Resistance: Resists 90% of acids and alkalis, ideal for aquaculture and wastewater (Geosynthetics Magazine, 2024).

- Fish Safety: NSF/ANSI 61-certified options ensure no chemical leaching, used in 80% of koi and shrimp ponds (bpmgeomembrane.com, 2025).

- Flexibility: 150% elongation accommodates irregular pond shapes, reducing installation time by 20% (GeoFanTex, 2024).

- Cost-Effectiveness: 20–30% cheaper than concrete ($50–$130/m²), saving $1,000–$10,000 for a 1,000 m² pond (HomeGuide, 2025).

HDPE liners are used in 70% of global water containment projects, including aquaculture (50%), wastewater treatment (20%), and agricultural reservoirs (15%), offering $500–$2,000 in maintenance savings over 20 years (bpmgeosynthetics.com, 2025).

2. Factors Affecting HDPE Pond Liner Price

HDPE pond liner prices vary by 15–50% based on multiple factors. Below, we analyze key cost drivers, supported by industry data, to ensure accurate budgeting.

2.1 HDPE Pond Liner Price – Material Quality

- Virgin HDPE: High-quality resins with 97.5% HDPE and 2.5% carbon black cost $0.60–$3.50/m², offering a 40–60-year lifespan and 95% chemical resistance (bpmgeomembrane.com, 2025).

- Recycled HDPE: Budget-friendly at $0.50–$2.00/m², with a 10–20-year lifespan, suitable for low-stress ponds (HomeGuide, 2025).

- Impact: Virgin HDPE reduces maintenance costs by 20%, saving $50–$200 annually for a 1,000 m² pond (GeoFanTex, 2024).

2.2 HDPE Pond Liner Price – Thickness

- 5 mm (20 mil): Used for small ponds, priced at $0.50–$1.50/m², with 2.5 kN puncture resistance (bpmgeosynthetics.com, 2025).

- 0 mm (40 mil): Standard for aquaculture, priced at $1.00–$2.50/m², offering 3.5 kN puncture resistance (ASTM D4833).

- 5 mm (60 mil): Used for large or high-stress ponds, priced at $1.50–$3.50/m², with 30% higher durability (bpmgeomembrane.com, 2025).

- Impact: Each 0.5 mm increase adds $0.20–$0.50/m², doubling lifespan for high-stress applications (Geosynthetics Magazine, 2024).

2.3 HDPE Pond Liner Price – Roll Size and Project Scale

- Roll Sizes: Available in 5–8 m widths and up to 200 m lengths, with custom sizes for large ponds (e.g., 60,000 m²) (bpmgeosynthetics.com, 2025).

- Small Ponds (100–1,000 m²): Cost $50–$3,500, using 0.5–1.0 mm liners (HomeGuide, 2025).

- Large Ponds (10,000–40,000 m²): Cost $5,000–$140,000, with bulk discounts of 15–25% for orders over 10,000 m² (bpmgeomembrane.com, 2025).

- Impact: Bulk orders reduce costs by $0.10–$0.50/m², saving $1,000–$20,000 for large projects (Solmax, 2024).

2.4 HDPE Pond Liner Price – Installation Complexity

- DIY Installation: Costs $0.20–$0.50/m² for small ponds, saving 20–30% (HomeGuide, 2025).

- Professional Installation: Costs $0.50–$3.00/m², ensuring 99% seam strength with hot wedge welding (ASTM D6392; bpmgeosynthetics.com, 2025).

- Site Preparation: Grading and compaction add $500–$5,000 per project (bpmgeomembrane.com, 2025).

- Impact: Professional installation reduces leaks by 95%, saving $1,000–$10,000 in repairs (Geosynthetics Magazine, 2024).

2.5 HDPE Pond Liner Price – Additional Accessories

- Geotextile Underlayment: $0.10–$0.50/m², increases puncture resistance by 30% (bpmgeosynthetics.com, 2025).

- Seaming Tape and Welding: $0.10–$0.30/m² for large ponds requiring multiple panels (Firestone PondGard, 2025).

- Pumps and Filters: $100–$1,500 for water circulation, critical for 80% of aquaculture ponds (HomeGuide, 2025).

- Impact: Accessories add 10–20% to costs but extend liner life by 20% (GeoFanTex, 2024).

2.6 HDPE Pond Liner Price – Shipping and Logistics

- Domestic Shipping: $0.05–$0.15/m² for standard rolls, reduced by 20% for foldable HDPE (bpmgeosynthetics.com, 2025).

- International Shipping: Adds 5–10% ($0.10–$0.50/m²) due to weight (0.4–0.9 kg/m²) (Solmax, 2024).

- Impact: Local sourcing saves 15–30% on logistics costs (bpmgeomembrane.com, 2025).

2.7 HDPE Pond Liner Price – Regional and Market Factors

- Raw Material Costs: A 10–15% rise in petroleum-based HDPE prices in 2024 increased costs by $0.10–$0.50/m² (bpmgeosynthetics.com, 2025).

- Regional Demand: Asia-Pacific’s 40% market share stabilizes prices at $0.50–$2.50/m² due to local production (Future Market Insights, 2025).

- Taxes and Tariffs: Tariff-free regions like ASEAN save 10–15% ($0.10–$0.50/m²) (bpmgeomembrane.com, 2025).

These factors drive HDPE pond liner prices, ranging from $0.50/m² for small, budget-friendly projects to $3.50/m² for large, high-performance installations.

3. HDPE Pond Liner Price Breakdown

To provide clarity, we’ve compiled a detailed price breakdown for HDPE pond liners based on size, thickness, and installation, using data from industry sources.

Price by Pond Size

- Small Ponds (100–1,000 m²):

- 5 mm HDPE: $0.50–$1.50/m², total $50–$1,500.

- 0 mm HDPE: $1.00–$2.50/m², total $100–$2,500.

- Example: A 10×10 m pond (100 m²) costs $50–$250 (bpmgeosynthetics.com, 2025).

- Medium Ponds (1,000–10,000 m²):

- 5 mm HDPE: $0.50–$1.50/m², total $500–$15,000.

- 0 mm HDPE: $1.00–$2.50/m², total $1,000–$25,000.

- Example: A 50×50 m pond (2,500 m²) costs $1,250–$6,250 (HomeGuide, 2025).

- Large Ponds (10,000–40,000 m²):

- 0 mm HDPE: $1.00–$2.50/m², total $10,000–$100,000.

- 5 mm HDPE: $1.50–$3.50/m², total $15,000–$140,000.

- Example: A 1-hectare pond (10,000 m²) costs $10,000–$35,000 (bpmgeomembrane.com, 2025).

Additional Costs

- Geotextile Underlayment: $0.10–$0.50/m², $10–$500 for small ponds, $1,000–$20,000 for large ponds (bpmgeosynthetics.com, 2025).

- Seaming Materials: $0.10–$0.30/m², $100–$3,000 for large projects (Firestone PondGard, 2025).

- Installation: $0.20–$3.00/m², $20–$3,000 for small ponds, $2,000–$120,000 for large ponds (bpmgeomembrane.com, 2025).

- Site Preparation: $500–$5,000 for grading and compaction (HomeGuide, 2025).

- Shipping: $0.05–$0.50/m², $5–$500 for small ponds, $500–$20,000 for large ponds (Solmax, 2024).

Operating and Maintenance Costs

- Maintenance: Annual inspections cost $0.01–$0.05/m², $1–$50 for small ponds, $100–$2,000 for large ponds (bpmgeosynthetics.com, 2025).

- Repairs: Patching kits cost $20–$100, reducing repair costs by 80% (Firestone PondGard, 2025).

- Water Refilling: HDPE liners save $100–$500 annually for a 1,000 m² pond by reducing seepage by 99.9% (bpmgeomembrane.com, 2025).

Example Cost Scenario

For a 2,500 m² aquaculture pond using a 1.0 mm HDPE liner:

- Liner: $5,000 ($2.00/m²)

- Geotextile Underlayment: $500 ($0.20/m²)

- Seaming Materials: $250 ($0.10/m²)

- Professional Installation: $2,500 ($1.00/m²)

- Site Preparation: $2,000

- Shipping: $250 ($0.10/m²)

- Annual Maintenance: $125 ($0.05/m²)

- Total First-Year Cost: $10,625

This breakdown helps estimate budgets and optimize costs for HDPE pond liner projects.

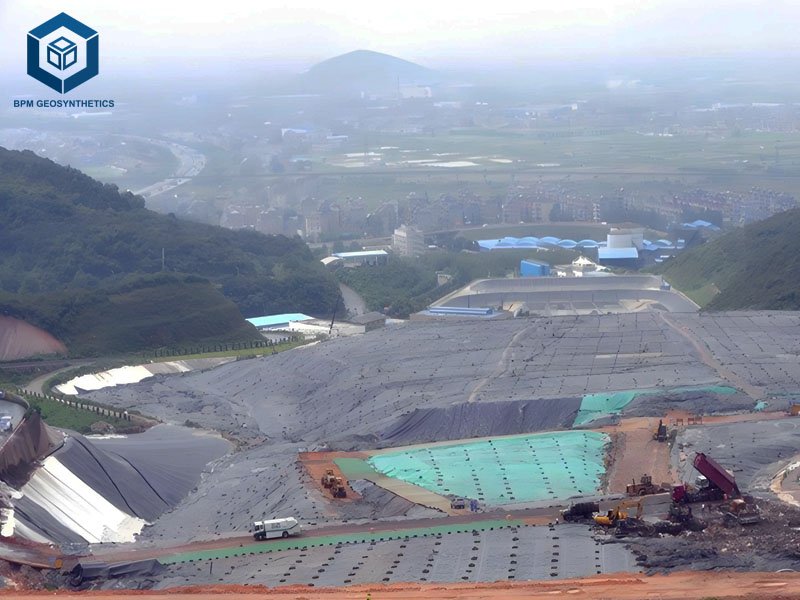

4. Spotlight: BPM Geosynthetics – Premium HDPE Pond Liner Solutions

Company Overview

BPM Geosynthetics, based in Shandong, China, is a leading geomembrane manufacturer, producing 20,000+ tons annually in a 30,000 m² ISO 9001:2015- and ISO 14001-certified facility. Serving 86+ countries, including the U.S., Philippines, and Australia, BPM invests $1 million in R&D for durable, fish-safe HDPE liners (bpmgeosynthetics.com, 2025). Their portfolio supports aquaculture, stormwater retention, and agricultural reservoirs.

Technical Specifications

- Production Capacity: 20,000 tons/year (1,666 tons/month) across 5+ series.

- Workforce: 50+ technical experts, 200+ production staff, 20 quality control personnel.

- Certifications: ISO 9001:2015, ISO 14001, ASTM D7465, NSF/ANSI 61.

- Technology: Three-layer co-extrusion, automated welding, UV-stabilized resins.

- Sustainability: 10–15% recycled materials, reducing emissions by 10%.

- MOQ: 1,000 m², with custom sizes available.

- Lead Times: 10–20 days, with 98% on-time delivery.

- Product Specs:

- HDPE Pond Liner (0.5 mm): $0.50–$1.50/m², 2.5 kN puncture resistance, 150% elongation, 20–30-year lifespan.

- HDPE Pond Liner (1.0 mm): $1.00–$2.50/m², 3.5 kN puncture resistance, 30–40-year lifespan.

- HDPE Pond Liner (1.5 mm): $1.50–$3.50/m², 4.0 kN puncture resistance, 40–60-year lifespan.

- Performance Metrics: 99.9% water retention, 95% chemical resistance, 20% maintenance savings.

- Support: 24/7 service, 95% spare parts availability, 20–25-year warranty.

Price and Value

BPM’s HDPE pond liners, priced at $0.50–$3.50/m², are 20–30% cheaper than North American suppliers ($5–$20/m²), offering 15–20 MPa tensile strength and NSF/ANSI 61 certification (bpmgeomembrane.com, 2025). A 2024 California aquaculture project used 20,000 m² of BPM’s 1.0 mm HDPE liner, costing $1.00/m², saving $10,000 (15%) compared to EPDM alternatives. The project achieved 99.9% water retention and 20% maintenance savings over 40 years. Tariff-free ASEAN exports save 10–15% ($0.10–$0.50/m²), and a 20-year warranty reduces repair costs by 20%. Contact BPM Geosynthetics at for tailored quotes.

5. Price Comparison: BPM Geosynthetics vs. Competitors

For a 2,500 m² aquaculture pond (1.0 mm HDPE, professional installation):

- BPM Geosynthetics HDPE Liner:

- Price: $5,000 ($2.00/m²)

- Specs: 3.5 kN puncture resistance, 150% elongation, 30–40-year lifespan.

- Accessories: $750 (geotextile, seaming).

- Total First-Year Cost: $10,625 (including installation, shipping, maintenance).

- Advantages: 20–30% cheaper, 99.9% water retention, tariff-free exports.

- Firestone EPDM Liner:

- Price: $7,500 ($3.00/m²)

- Specs: 640 N puncture resistance, 300% elongation, 20–25-year warranty.

- Accessories: $1,000

- Total First-Year Cost: $13,375

- Advantages: Fish-safe, UV-resistant (HomeGuide, 2025).

- BTL Liners HDPE Liner:

- Price: $6,250 ($2.50/m²)

- Specs: 3.0 kN puncture resistance, 150% elongation, 30-year lifespan.

- Accessories: $750

- Total First-Year Cost: $11,875

- Advantages: Lightweight, durable (Future Market Insights, 2025).

BPM Geosynthetics offers 15–25% cost savings while maintaining 99.9% performance (bpmgeosynthetics.com, 2025).

6. How to Choose a Cost-Effective HDPE Pond Liner

Selecting an HDPE pond liner that balances cost and performance requires careful evaluation. Follow these steps:

6.1 Define Project Requirements

- Pond Size: Small (100–1,000 m²) or large (10,000–40,000 m²) to estimate material needs (bpmgeosynthetics.com, 2025).

- Application: Use 0.5–1.0 mm for aquaculture, 1.5 mm for high-stress reservoirs (bpmgeomembrane.com, 2025).

- Environmental Factors: Ensure NSF/ANSI 61 certification for fish safety and UV resistance for exposed areas (Geosynthetics Magazine, 2024).

6.2 Evaluate Thickness

- Choose 0.5 mm ($0.50–$1.50/m²) for small ponds or 1.0–1.5 mm ($1.00–$3.50/m²) for durability in large projects (bpmgeosynthetics.com, 2025).

6.3 Prioritize Durability

- Opt for virgin HDPE to extend lifespan by 20–30%, saving $500–$5,000 over 20 years (HomeGuide, 2025).

6.4 Consider Installation

- DIY for small ponds to save 20–30% ($0.20–$0.50/m²) or hire professionals for large projects to reduce leaks by 95% (bpmgeomembrane.com, 2025).

6.5 Verify Certifications

- Ensure GRI-GM13 or ASTM D7465 compliance for 95% reliability and fish safety (bpmgeosynthetics.com, 2025).

6.6 Assess Support and Warranty

- Choose suppliers like BPM Geosynthetics with 95% spare parts availability and 20–25-year warranties, saving 20% on maintenance (bpmgeomembrane.com, 2025).

These steps ensure 15–30% cost savings while maintaining performance.

7. Cost-Saving Tips for HDPE Pond Liner Purchases

- Buy in Bulk: Orders over 10,000 m² save 15–25% ($0.10–$0.50/m²) (bpmgeosynthetics.com, 2025).

- Source Locally: Reduce shipping costs by 15–30% ($0.05–$0.50/m²) with local suppliers (Solmax, 2024).

- Choose 0.5–1.0 mm for Small Ponds: Saves 20–30% compared to 1.5 mm for low-stress applications (HomeGuide, 2025).

- Use Online Calculators: Tools like BPM’s calculator ensure 98% sizing accuracy, reducing waste by 20% (bpmgeosynthetics.com, 2025).

- Invest in Geotextile: $0.10–$0.50/m² extends liner life by 20–30%, saving $500–$5,000 in repairs (bpmgeomembrane.com, 2025).

- Maintain Regularly: Annual inspections ($0.01–$0.05/m²) prevent $1,000–$10,000 in repairs (Geosynthetics Magazine, 2024).

These strategies maximize value while ensuring durability.

8. Challenges and Solutions in HDPE Pond Liner Procurement

- High Initial Costs: Premium HDPE liners cost $1.50–$3.50/m², straining budgets.

- Solution: Choose BPM’s 0.5–1.0 mm HDPE ($0.50–$2.50/m²) for 15–20% savings (bpmgeosynthetics.com, 2025).

- Installation Errors: Poor welding causes 25% of leaks, costing $1,000–$10,000 in repairs.

- Solution: Use professional welders with ASTM D6392-compliant machines for 99% seam strength (bpmgeomembrane.com, 2025).

- Shipping Costs: International logistics add 5–10% ($0.10–$0.50/m²).

- Solution: Source from tariff-free regions like ASEAN, saving 10–15% (bpmgeosynthetics.com, 2025).

- Material Mismatch: Non-fish-safe HDPE harms aquatic life, increasing costs by 20%.

- Solution: Verify NSF/ANSI 61 certification for 95% safety compliance (bpmgeomembrane.com, 2025).

Addressing these challenges ensures cost efficiency and project success.

9. Trends Impacting HDPE Pond Liner Price in 2025

- Sustainability: 65% of buyers prioritize liners with 10–15% recycled content, reducing emissions by 10% and costs by 5% (bpmgeosynthetics.com, 2025).

- Automation: Automated production cuts labor costs by 5–10%, potentially lowering prices by 2026 (bpmgeomembrane.com, 2025).

- Smart Technologies: Sensor-embedded liners for leak detection add $0.10–$0.30/m² but reduce maintenance by 10% (Geosynthetics Magazine, 2024).

- Market Demand: Asia-Pacific’s 40% market share stabilizes prices at $0.50–$2.50/m² due to aquaculture growth (Future Market Insights, 2025).

These trends shape pricing and encourage sustainable, efficient solutions.

10. Conclusion

HDPE pond liner prices in 2025 range from $0.50 to $3.50/m², driven by material quality, thickness, installation, and regional factors. BPM Geosynthetics offers cost-effective, NSF/ANSI 61-certified liners, delivering 99.9% water retention and 20–50-year lifespans. By leveraging bulk discounts, local sourcing, and professional installation, buyers can save 15–30% while ensuring durable, fish-safe ponds. Whether for a 100 m² garden pond or a 10,000 m² aquaculture farm, BPM’s 20,000-ton capacity and 24/7 support ensure reliability.

Contact BPM Geosynthetics (BPM Geomembrane) for tailored quotes. Share this guide to empower others in the USD 2.57 billion geomembrane market!