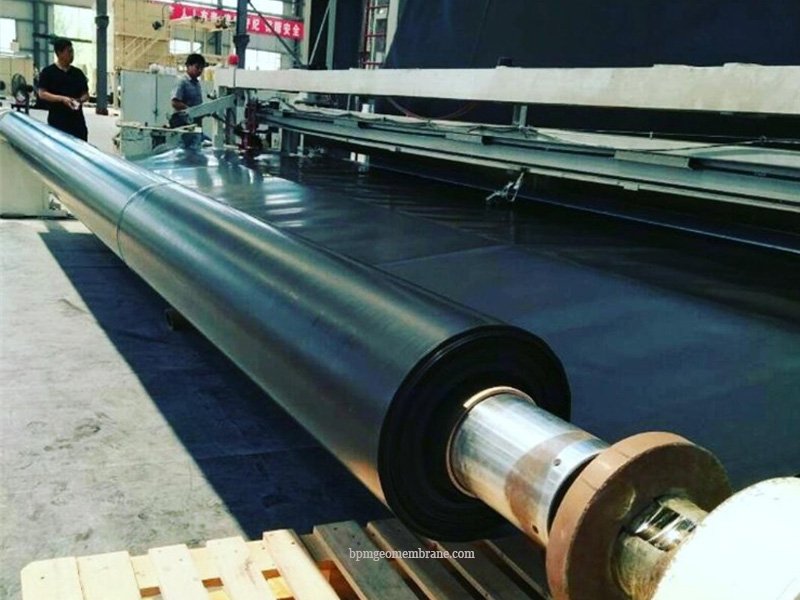

HDPE waterproofing membrane, also known waterproofing HDPE geomembrane, is a type of geomembrane extensively applied in civil engineering and environmental projects. BPM HDPE waterproofing membrane offers a great range of advantage features such as impressive durability, flexibility and chemical resistance compared to other waterproofing materials. From its to its relatively fast and easy installation process, HDPE membrane waterproofing is an ideal solution to water, moisture and gas while providing good puncture resistance during placement of impermeable barrier for many types of projects.

BPM Geomembrana is the OEM/ODM HDPE geomembrane manufacturer and supplier, We have 17+ years geomembrane industrial experiences. In this article, let us delve into the definition, advantage, application and installation of HDPE waterproofing membrane, we think it will helpful for you.

1. What is HDPE Waterproofing Membrane

HDPE waterproofing membrane, also known as HDPE geomembrane liner, is specifically designed to function as an impermeable barrier, effectively preventing the passage of water, moisture, and gas. It offers exceptional puncture resistance, making it suitable for use during the placement of reinforcement bars in construction projects. This synthetic membrane, known as HDPE (High-Density Polyethylene), is widely utilized for waterproofing applications in various construction projects.

Constructed from high-density polyethylene, a durable and flexible plastic material, these membranes provide reliable protection against water penetration. They act as a shield, safeguarding structures from potential damage caused by moisture. With its flexibility and durability, the HDPE membrane ensures long-lasting performance.

HDPE waterproofing membrane has excellent resistance to water and chemicals. It effectively withstands exposure to different types of liquids and chemicals, ensuring the integrity of the structure it is applied to.

The HDPE waterproofing membrane plays a crucial role in maintaining the structural integrity of buildings, basements, and other below-ground structures. By acting as a reliable barrier, it helps prevent water-related issues such as leaks, dampness, and mold growth.

HDPE waterproofing membrane offers flexibility, durability, and superior resistance to water and chemicals. Its reliable performance and protective properties make it a valuable choice for various construction applications that require effective waterproofing solutions.

BPM Geomembrane is the trusted HDPE geomembrane manufacturer and supplier, we offers a wide range of HDPE waterproofing membrane with custom size and thickness at best factory price.

2. What Are Advantages of HDPE Waterproofing Membranes?

HDPE waterproofing membranes is their superior resistance to ultraviolet (UV) radiation. UV rays from the sun can degrade and weaken materials over time. However, HDPE membranes are specifically formulated to withstand prolonged exposure to sunlight without deteriorating, ensuring their long-term performance.

HDPE membranes exhibit a high puncture resistance, minimizing the risk of damage during installation or due to external factors such as roots or sharp objects. This puncture resistance is crucial for maintaining the integrity of the waterproofing system and preventing water infiltration.

The versatility of HDPE membranes extends to their ease of installation. Depending on the specific requirements and conditions of the project, contractors can choose from various installation methods. Torch-applied membranes involve heating the underside of the membrane with a torch to create a secure bond with the substrate. Adhesive-based membranes utilize specialized adhesives to adhere the membrane to the surface. Mechanical fastening methods involve securing the membrane using fasteners such as screws or nails.

Proper maintenance is essential for maximizing the lifespan and performance of HDPE waterproofing membranes. Regular inspections should be conducted to identify any signs of damage, including punctures, cracks, or tears. Additionally, it is crucial to keep the membrane surface clean by removing debris, dirt, and vegetation, as these can compromise the effectiveness of the waterproofing system.

3. Specifications of HDPE Waterproofing Geomembrane

| 1 | Thickness | 0.1mm-3.0mm |

| 2 | Standard | GB and GRI-GM13 Standard |

| 3 | Width | 1m-10m, can be customized |

| 4 | Length | 30m-210m, can be customized |

| 5 | Application | Fish shrimp, landfill, dam, canal, mining, water pond etc. |

HDPE waterproofing membranes are available in various thicknesses and sizes, HDPE membranes can be installed using different methods such as torching, adhesion, or mechanical fastening. The construction industry extensively employs these membranes to waterproof structures like buildings, tunnels, bridges, and reservoirs, providing long-lasting protection against water intrusion.

The inherent properties of HDPE make it an ideal choice for waterproofing applications. High-density polyethylene exhibits excellent tensile strength, flexibility, and resistance to impact, ensuring the longevity and durability of the waterproofing system. Additionally, HDPE membranes possess outstanding chemical resistance, making them impervious to the corrosive effects of various substances commonly encountered in construction environments.

4. Where Is HDPE Waterproofing Membrane Used For?

HDPE waterproofing membranes are used in various applications where effective water protection is required. Some common areas where HDPE waterproofing membranes are utilized include:

4.1 Concrete Structures

HDPE membranes are widely used to waterproof concrete structures such as basements, retaining walls, and underground parking lots. They create a reliable barrier that prevents water from infiltrating the concrete, protecting it from moisture-related damage.

4.2 Roofs and Terraces

HDPE waterproofing membranes are suitable for waterproofing flat roofs, terraces, and balconies. They provide a durable and flexible layer that shields the underlying structure from water penetration, ensuring a watertight and leak-free surface.

4.3 Foundations

HDPE membranes are commonly employed in foundation waterproofing. They are applied to the exterior of foundation walls to prevent water from seeping into the building, safeguarding against potential moisture-related issues.

4.4 Tunnels and Subways

HDPE waterproofing membranes are used in the waterproofing of tunnels and subways to maintain a dry and safe environment. They are applied to the tunnel walls and ceilings to prevent water ingress and protect the structural integrity.

4.5 Landfill Liners

HDPE membranes are utilized as liners in landfills to prevent the leaching of contaminants into the surrounding soil and groundwater. They provide an impermeable barrier that ensures proper containment of waste materials.

4.6 Swimming Pools and Water Lining

HDPE membranes are employed in the construction of swimming pools and water features to provide a waterproofing layer. They ensure that water remains within the designated area and do not seep into the surrounding structures.

5. How To Install HDPE Waterproofing Membranes

Addressing drainage issues is another important aspect of maintenance. Ensuring that the drainage system is functioning correctly and directing water away from the membrane prevents water pooling and excessive stress on the membrane.

Avoiding contact with sharp objects is essential to prevent punctures or damage to the membrane. During construction or maintenance activities, care should be taken to prevent tools, equipment, or other objects from coming into contact with the membrane surface.

Prompt repairs are necessary to address any identified damage or issues. Small punctures or tears can typically be repaired using compatible patching materials and adhesives recommended by the manufacturer.

In cases where the HDPE membrane is exposed to direct sunlight, applying a protective layer, such as a UV-resistant coating, can extend its lifespan by shielding the membrane from the harmful effects of UV radiation.

It is important to note that specific maintenance requirements may vary depending on the manufacturer’s recommendations, the type of HDPE membrane, and the specific application. Therefore, referring to the manufacturer’s guidelines and specifications for maintenance practices is always recommended for the best results.

HDPE waterproofing membranes offer a reliable and durable solution for protecting structures from water infiltration. Their exceptional resistance to water, chemicals, UV rays, and punctures make them a popular choice in the construction industry. With proper installation and maintenance, HDPE membranes can provide long-lasting waterproofing performance, ensuring the integrity and longevity of structures.

6. What Are Some Common Maintenance Practices for HDPE Membrane?

To ensure the longevity and effectiveness of HDPE waterproofing membranes, several common maintenance practices are typically recommended.

Regular inspections are vital to identify any signs of damage. Routine checks should be performed to look for punctures, cracks, tears, and any signs of separation or deterioration along the seams and edges of the membrane. By conducting these inspections, potential issues can be identified early on, allowing for prompt repairs and maintenance.

Keeping the surface of the membrane clean is essential to prevent potential damage and ensure proper water runoff. It is important to remove any debris, dirt, or vegetation that may accumulate on the membrane surface. Regular cleaning helps maintain the integrity of the membrane and prevents the accumulation of substances that could compromise its performance.

Addressing drainage issues is crucial for maintaining the effectiveness of the waterproofing system. It is important to ensure that the drainage system is functioning properly, directing water away from the membrane. Clogged or malfunctioning drains can lead to water pooling, which can exert additional stress on the membrane and compromise its ability to prevent water infiltration. Regularly inspecting and maintaining the drainage system is necessary to avoid such issues.

Avoiding contact with sharp objects is another key maintenance practice. Placing or dragging sharp objects across the membrane surface can result in punctures or damage to the material. During construction or maintenance activities, care should be taken to prevent tools, equipment, or any other objects from coming into contact with the membrane. By avoiding sharp objects, the risk of compromising the integrity of the membrane is minimized.

Prompt repairs are essential when damage or issues are identified during inspections. Even small punctures or tears should be addressed promptly to prevent further damage. Compatible patching materials and adhesives specified by the manufacturer should be used for repairs to ensure the proper functioning of the membrane.

If the HDPE membrane is exposed to direct sunlight, protecting it from UV radiation is crucial. Applying a protective layer, such as a UV-resistant coating, can shield the membrane from the harmful effects of UV rays. UV exposure over time can degrade the membrane and reduce its performance. Therefore, protecting the membrane from UV radiation can help prolong its lifespan.

It is important to note that specific maintenance requirements may vary depending on the manufacturer’s recommendations, the type of HDPE membrane, and the specific application. To ensure the best results, it is always recommended to refer to the manufacturer’s guidelines and specifications for maintenance practices. These guidelines will provide detailed and accurate instructions tailored to the specific type of HDPE membrane being used.

By following these common maintenance practices and adhering to manufacturer recommendations, the lifespan and performance of HDPE waterproofing membranes can be maximized, ensuring effective protection against water infiltration and maintaining the integrity of structures for years to come.