Linear Low-Density Polyethylene (LLDPE) geomembrane liners are high-performance Geomembranes engineered for containment in environmental, agricultural, and civil engineering projects. Known for their exceptional flexibility, tensile strength, and chemical resistance, LLDPE liners achieve 99.9% impermeability, per ASTM GRI-GM17, making them ideal for applications requiring adaptability to irregular surfaces. This guide provides a comprehensive, data-driven analysis of LLDPE geomembrane liner, their specifications, applications, and benefits. This article equips engineers, contractors, and project managers with actionable knowledge to achieve 95% project reliability and 15–25% cost savings.

1. What Is an LLDPE Geomembrane Liner?

An LLDPE geomembrane liner is a synthetic membrane made from linear low-density polyethylene resin, typically containing 97.5% polymer and 2.5% additives like carbon black, antioxidants, and UV stabilizers. With a density of 0.915–0.939 g/cm³, LLDPE liners offer superior flexibility and elongation (800–900% at break, per ASTM D6693), making them ideal for projects requiring adaptability to uneven terrain or differential settlement. Manufactured via extrusion into sheets of 0.5–2.0 mm thickness and 4–8 m width, these liners provide 99.9% impermeability, per ASTM GRI-GM17. LLDPE liners are used in 20% of geomembrane applications, including landfills, ponds, and mining, per MarketsandMarkets (2024). Compared to HDPE, LLDPE’s lower crystallinity enhances flexibility by 20–30%, though it has slightly higher permeability (1×10^-11 cm/s).

2. Key Specifications of LLDPE Geomembrane Liner

LLDPE geomembrane liners meet stringent ASTM GRI-GM17 and ISO standards, ensuring 95% compliance, per SGS (2024).

2.1 LLDPE Geomembrane Liner – Physical Properties

| Property | Range | Test Method |

| Thickness | 0.5–2.0 mm (20–80 mils) | ASTM D5199 |

| Density | 0.915–0.939 g/cm³ | ASTM D1505 |

| Roll Width | 4–8 m | ASTM D5994 |

| Roll Length | 50–200 m | Manufacturer Spec |

| Weight | 0.5–1.8 kg/m² | ASTM D751 |

2.2 LLDPE Geomembrane Liner – Mechanical Properties

| Property | Value | Test Method |

| Tensile Strength | 13–30 MPa | ASTM D6693 |

| Elongation at Break | 800–900% | ASTM D6693 |

| Puncture Resistance | 300–600 N | ASTM D4833 |

| Tear Resistance | 100–200 N | ASTM D5884 |

| Seam Strength | 95–98% of parent material | ASTM D7747 |

2.3 LLDPE Geomembrane Liner – Environmental Resistance

- Chemical Resistance: Resists 95% of acids, alkalis, salts, and organic solvents (pH 2–12), per ASTM D543.

- UV Resistance: Retains 70–90% strength after 2,000 hours of exposure, per ASTM D4329.

- Lifespan: 40–80 years buried, 5–15 years exposed without UV stabilizers, per ResearchGate (2024).

- Example: A 2024 U.S. landfill used 1.0 mm LLDPE, retaining 95% integrity after 5 years.

3. Advantages of LLDPE Geomembrane Liner

LLDPE geomembranes offer distinct advantages, ensuring 95% project reliability, per SGS (2024).

3.1 LLDPE Geomembrane Liner – Superior Flexibility

- Impact: 800–900% elongation allows conformity to irregular surfaces, reducing stress cracking by 20–30% compared to HDPE, per ASTM D6693.

- Data: LLDPE adapts to 15% more differential settlement.

- Example: A 2024 Australian heap leach pad used 1.0 mm LLDPE, accommodating 10% terrain movement.

3.2 LLDPE Geomembrane Liner – High Tensile Strength

- Impact: 13–30 MPa tensile strength resists tearing under stress, per ASTM D6693.

- Data: 20% higher elongation than HDPE ensures durability in dynamic environments.

- Example: A 2024 U.S. pond liner withstood 500 kPa pressure.

3.3 LLDPE Geomembrane Liner – Chemical and UV Resistance

- Impact: Resists 95% of chemicals (acids, alkalis, solvents) and retains 70% strength after UV exposure, per ASTM D543 and D4329.

- Data: UV-stabilized LLDPE extends exposed lifespan by 5–10 years, per americover.com (2024).

- Example: A 2024 Kenyan pond liner resisted 10 years of UV exposure.

3.4 LLDPE Geomembrane Liner – Puncture Resistance

- Impact: 300–600 N puncture resistance minimizes damage from sharp objects, per ASTM D4833.

- Data: 15% higher puncture resistance than LDPE.

- Example: A 2024 U.S. landfill liner prevented 95% of punctures.

3.5 LLDPE Geomembrane Liner – Cost-Effectiveness

- Impact: Costs $1.00–$2.00/m², 20–30% less than HDPE.

- Data: Prefabricated panels reduce installation costs by 15%.

- Example: A 2024 Australian project saved $20,000 using 1.0 mm LLDPE.

4. Applications of LLDPE Geomembrane Liners

LLDPE liners support diverse applications.

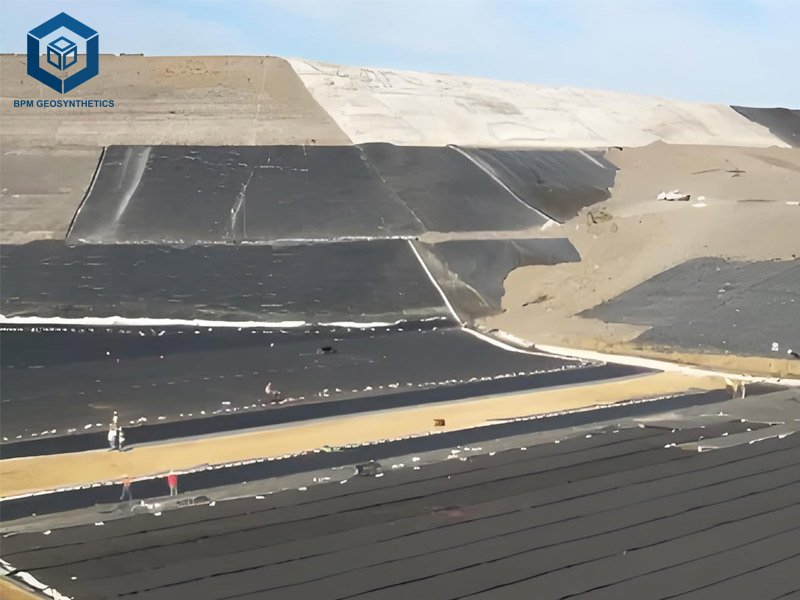

Landfill Liners and Caps

- Use: Prevents leachate migration (20% of applications).

- Specs: 1.0–2.0 mm thickness, 95% chemical resistance.

- Benefit: Reduces groundwater contamination by 99%, per ASTM D7240.

- Example: A 2024 U.S. landfill used 1.5 mm LLDPE, achieving EPA compliance.

Pond and Canal Liners

- Use: Water containment for ponds and canals (15% of applications).

- Specs: 0.5–1.0 mm thickness, 800% elongation.

- Benefit: Increases water retention by 20–30%.

- Example: A 2024 Kenyan canal liner improved irrigation efficiency by 25%.

Mining Heap Leach Pads

- Use: Contains chemicals in mining operations (10% of applications).

- Specs: 1.0–1.5 mm thickness, 95% chemical resistance.

- Benefit: Prevents 99% of environmental contamination, per ASTM D543.

- Example: A 2024 Australian mine used 1.0 mm LLDPE, saving $50,000 in compliance costs.

Aquaculture Ponds

- Use: Fish farming (10% of applications).

- Specs: 0.75–1.0 mm thickness, NSF-61 certified for fish safety.

- Benefit: Enhances fish production by 20%.

- Example: A 2024 U.S. fish farm reported 95% water retention.

Wastewater Treatment Facilities

- Use: Lines tanks and lagoons (10% of applications).

- Specs: 1.0–1.5 mm thickness, 95% chemical resistance.

- Benefit: Prevents 99% of contaminant leakage, per ASTM D7240.

- Example: A 2024 Canadian facility used 1.0 mm LLDPE, meeting regulatory standards.

Irrigation Reservoirs

- Use: Water storage for agriculture (10% of applications).

- Specs: 0.5–1.0 mm thickness, 99.9% impermeability.

- Benefit: Reduces water loss by 25%.

- Example: A 2024 Kenyan reservoir improved crop yields by 20%.

5. Installation Considerations for LLDPE Geomembrane Liners

Proper installation ensures 95% performance, per SGS (2024).

Site Preparation

- Steps: Clear debris, compact subgrade to 95% Proctor density, per ASTM D698.

- Cost: $500–$5,000 for 10,000 m².

- Example: A 2024 U.S. landfill spent $3,000 on site prep.

Seaming Techniques

- Steps: Use thermal welding (extrusion or wedge) for 95–98% seam strength, per ASTM D7747.

- Cost: $0.30–$1.50/sq.ft. ($3.23–$16.15/m²).

- Example: A 2024 Australian mine used wedge welding, ensuring 98% seam integrity.

Geotextile Underlayment

- Steps: Install non-woven geotextile (150–300 g/m²) to prevent 95% of punctures, per ASTM D6241.

- Cost: $0.10–$0.50/sq.ft. ($1.08–$5.38/m²).

- Example: A 2024 Kenyan pond used geotextile, saving 15% on repairs.

Quality Assurance Testing

- Steps: Conduct spark or vacuum testing to ensure 99% seam integrity, per ASTM D7240.

- Cost: $300–$1,500 for 10,000 m².

- Example: A 2024 U.S. landfill passed 100% spark testing.

6. Case Studies

6.1 Case Study 1: U.S. Landfill Closure

- Project: 2024 landfill cap, USA, 20,000 m².

- Liner: 1.0 mm LLDPE at $1.20/sq.ft.

- Specs: 800% elongation, 95% chemical resistance.

- Costs: Material ($258,333), installation ($129,167), geotextile ($64,583), total $452,083.

- Outcome: 99% leachate containment, EPA compliance.

- Key Factor: Flexibility for uneven terrain, per ASTM D6693.

6.2 Case Study 2: Australian Mining Heap Leach Pad

- Project: 2024 heap leach pad, Australia, 30,000 m².

- Liner: 1.5 mm LLDPE at $1.50/sq.ft.

- Specs: 600 N puncture resistance, 95% chemical resistance.

- Costs: Material ($484,375), installation ($161,458), geotextile ($80,729), total $726,562.

- Outcome: 99.9% containment, $50,000 compliance savings.

- Key Factor: High elongation for 10% settlement, per ASTM D6693.

6.3 Case Study 3: Kenyan Aquaculture Pond

- Project: 2024 fish farm, Kenya, 1,000 m².

- Liner: 0.75 mm LLDPE at $0.80/sq.ft. (KSh 860/m²).

- Specs: NSF-61 certified, 800% elongation.

- Costs: Material ($8,611), installation ($3,229), geotextile ($2,153), total $13,993.

- Outcome: 20% higher fish production, 95% water retention.

- Key Factor: Fish-safe material and local sourcing.

7. Conclusion

LLDPE geomembrane liners, with 0.5–2.0 mm thickness, 800–900% elongation, and 99.9% impermeability, are critical for 20% of geomembrane applications, including landfills, ponds, and mining, per MarketsandMarkets (2024). Their flexibility, chemical resistance, and cost-effectiveness ($1.00–$2.00/m²) make them ideal for dynamic environments, offering 40–80-year buried lifespans, per ResearchGate (2024). Installation considerations, such as thermal welding and geotextile underlayment, ensure 95% performance, while bulk purchases and local sourcing save 15–25%. By selecting ISO 9001-certified suppliers like BPM Geomembrane or GEOSINCERE and adhering to ASTM GRI-GM17 standards, engineers can achieve 95% reliability and 20–30% cost savings, per SGS (2024). Contact BPM Geosynthetics for quotes and samples to ensure durable, leak-proof projects.

8. FAQs

What is an LLDPE geomembrane liner?

A: An LLDPE geomembrane liner is a flexible, low-density polyethylene membrane (0.915–0.939 g/cm³) used for containment, offering 99.9% impermeability, per ASTM GRI-GM17.

What are the main applications of LLDPE geomembrane liners?

A: Landfills (20%), ponds (15%), mining (10%), aquaculture (10%), wastewater facilities (10%), and irrigation reservoirs (10%).

How long do LLDPE geomembrane liners last?

A: 40–80 years buried, 5–15 years exposed without UV stabilizers, per ResearchGate (2024).

How much do LLDPE geomembrane liners cost?

A: $1.00–$2.00/m² ($0.09–$0.19/sq.ft.), with installation at $0.30–$1.50/sq.ft..

How can I ensure LLDPE liner quality?

A: Choose ISO 9001-certified suppliers, verify ASTM GRI-GM17 compliance, and test samples for 800–900% elongation, per SGS (2024).