CASE STUDY

- Location : Australia

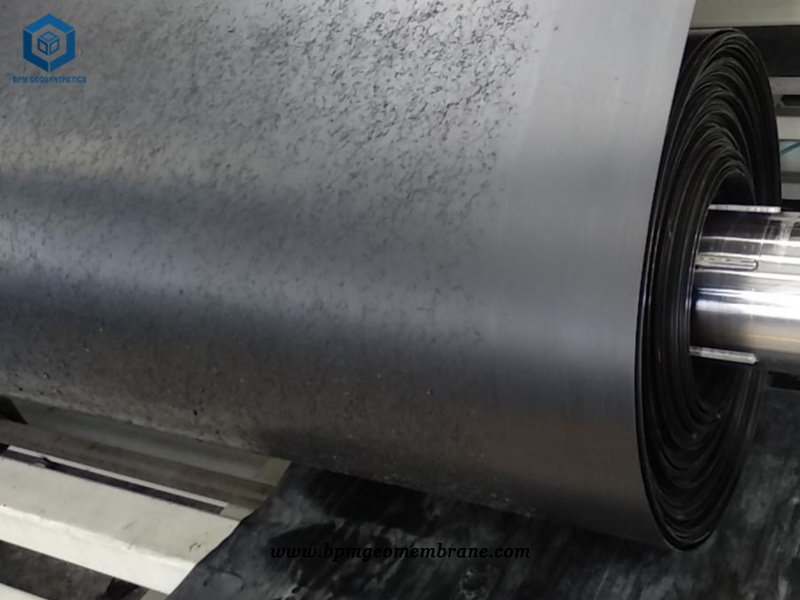

- Product(s) : HDPE Textured Geomembrane Liner

- Application : Tailing Project

Issue

Mine tailings are the finely ground residue from ore extraction. The grain size of the tailings depends on the nature of the ore and the milling process. Tailings are most often in the form of a wet slurry, are conventionally stored above-ground behind earthen dams which are the heavy pollution of engineering project, the storage and handling of tailings is a major environmental issue.Many tailings are toxic and must be kept perpetually isolated from the environment. whether it is raw materials or products, are dangerous goods that have great harm to the environment. If there is no good protection measures, once the toxic pollutants leak, it will lead to groundwater pollution, a serious threat to environmental safety. Australian customers decided to lay a layer of protective geomembrane to prevent seepage after the tailings excavation. However, due to the complex terrain of the construction site, the construction is relatively difficult. Tailings containment facilities are regarded as the world’s largest man-made objects.

Solution

For the mining tailings storage and treatment ponds, HDPE textured geomembrane is the ideal and cost effective solution for slope protection and dam reinforcement. The principle of this technology applied in complex broken open-air slope is show as followed. Impervious HDPE textured geomembrane liner can prevent rainwater from entering the soil and prevent loose soil from affecting soil under the action of rain. The one side textured surface performs high friction strength and stability to prevent the sliding surface mechanical parameters to reduce or the increase of self weight lead to the decline of slope stability and overall sliding. Through the application of HDPE anti-seepage geomembrane slope protection and reinforcement technology in the complex broken open-pit slope, even if there is a large range of through cracks in the slope under the action of rain, it can also prevent the slope from sliding.

Benefits

HDPE textured geomembrane liner is specially designed and fabricated for landfills and mining applications due to its advanced stabilization, excellent interface friction coefficient and inherent flexibility. As flexibility as our other geomembrane products, HDPE textured geomembranes have been widely in backfilled liner, retaining backfill on steep side, heap leach pads, landfill and pad base liner, water conservancy applications such as dam, reservoirs, sewage pools, swimming pools, buildings, underground buildings, garbage dumps and mining projects. At the same time, because of the advantages of simple construction technology, good robustness, low cost and strong adaptability, HDPE textured geomembrane has been widely promoted and applied in the reinforcement of complex broken open-air slope.

Features of HDPE Textured Geomembrane Liner

- Can be textured on one or both sides for your demands.

- Increased frictional coefficient for steep slopes.

- Outstanding ultraviolet and chemical resistance.

- Outstanding UV Environmental stress crack resistance.

- High tensile strength and low elongation.

- Excellent friction coefficient and tensile strength with Geotextile reinforcement performance.

- Excellent water impermeability, corrosion and aging resistance.

- Advanced stabilization.

- Impermeable, antifouling, antiskid function.

- Light weight, easy construction and good overall continuity.

Construction method of HDPE Textured Geomembrane Liner

Before laying impermeable membrane, the slope surface should be leveled to prevent sharp outburst, and then the loose soil should be covered with impermeable HDPE geomembrane.

1) It should be extended from the bottom to the high position, not too tight, and 1.50% margin should be reserved for local sinking and stretching. Considering the actual situation of the project, the slope is laid from top to bottom.

2) The two adjacent longitudinal joints shall not be in a horizontal line, and shall be staggered by more than 1m.

3) The longitudinal joint shall be more than 1.50M away from the dam foot and bending foot, and shall be set on the plane.

4) Slope first and then bottom.

5) When the slope is laid, the film spreading direction should be basically parallel to the maximum slope line.

Slope laying: before laying the anti-seepage geomembrane on the slope, the laying area shall be inspected and measured. According to the measured size, the anti-seepage geomembrane with matching size in the warehouse shall be transported to the anchorage ditch platform of phase I. during laying, the convenient way of “pushing” from top to bottom shall be adopted according to the actual site conditions. In the sector area, it should be cut reasonably to make the upper and lower ends firmly anchored.

Site bottom laying: before laying the anti-seepage geomembrane, the laying area shall be inspected and measured, and the anti-seepage membrane matched with the size in the warehouse shall be transported to the corresponding position according to the measured size. During laying, the anti-seepage membrane shall be pushed manually in a certain direction.

Alignment and alignment:The paving of BPM HDPE textured geomembrane, no matter the side slope or the bottom of the field, should be flat and straight to avoid wrinkles and ripples, so as to make the two geomembranes aligned and aligned. According to the design requirements, the lap width is generally about 10 cm.

Pressing: press the aligned and aligned BPM HDPE textured geomembrane with sand bags in time to prevent the wind from blowing and pulling. Laying in Anchorage ditch: at the top of anchorage ditch, a certain amount of impervious membrane shall be reserved according to the design requirements for local sinking and stretching.

Longitudinal joint: the uphill section is on the upper side and the downhill section is on the lower side, and sufficient lap length ≥ 15cm shall be reserved. The bentonite pad shall be laid in the area after passing the acceptance, and the manual “push paving” shall be carried out in a certain direction.

Specifications of HDPE Textured Geomembrane Liner for Tailing Project in Australia

- Total HDPE Textured Geomembrane quantity – 80,000 squares meters

- Thickness – 2.0mm

- Each roll size – 7m*50m

Summary

BPM geomembrane is manufactured by the high-quality polyethylene virgin resin as raw material, add carbon black, anti-aging agent, anti-ultraviolet absorber, stabilizer and other auxiliary materials formula, uses world-class fully automated geomembrane production equipment, through three-layer co-extrusion blow molding Or calendering process technology, produced, is an effective waterproof barrier type engineering material.

We had provided many types of effective and states of the art geomembranes and other geosynthetics to over 120 countries. Our main customers are from Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia etc.

In recent years, BPM had invested more than 2 million dollars into its modern manufacturing factory to improve the basic production facilities, manufacturing equipment, working conditions, employee salary and welfare, technical and teamwork training, etc.

Our modern factory is equipped with advanced machines like blowing film technology Geomembrane production line, extrusion technology Geomembrane production line, PET Geogrid production line, Geotextile production line and other special machines, which help us to keep high product quality, shorter delivery time and competitive cost to meet the demands of our worldwide customers. Most of our geomembranes and other geosynthetic products had been kept up with the international forefront counterparts. Some of them have enjoyed leading positions, especially smooth Geomembrane HDPE Liner and Composite Geomembrane Liner.

Welcome to visit our Geomembrane factory.

About BPM

As the the professional geomembrane manufacturer and supplier, BPM has been dedicated to supplying one stop geomembranes and services to worldwide customers since its foundation in 2010. Our main innovative, high quality geosynthetics products include geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids, etc. All BPM brand HDPE geomembranes have passed the certificates of the ISO9001, ISO14001, TUV, Soncap, SASO, BV certificates and the test of SGS and Intertek etc. Our geomembrane products have been exported to over 36 countries. If you have any questions or inquiries, please fill in and submit the form to contact us.